Using method of floating upper filtering type filter capable of cleaning by backflushing

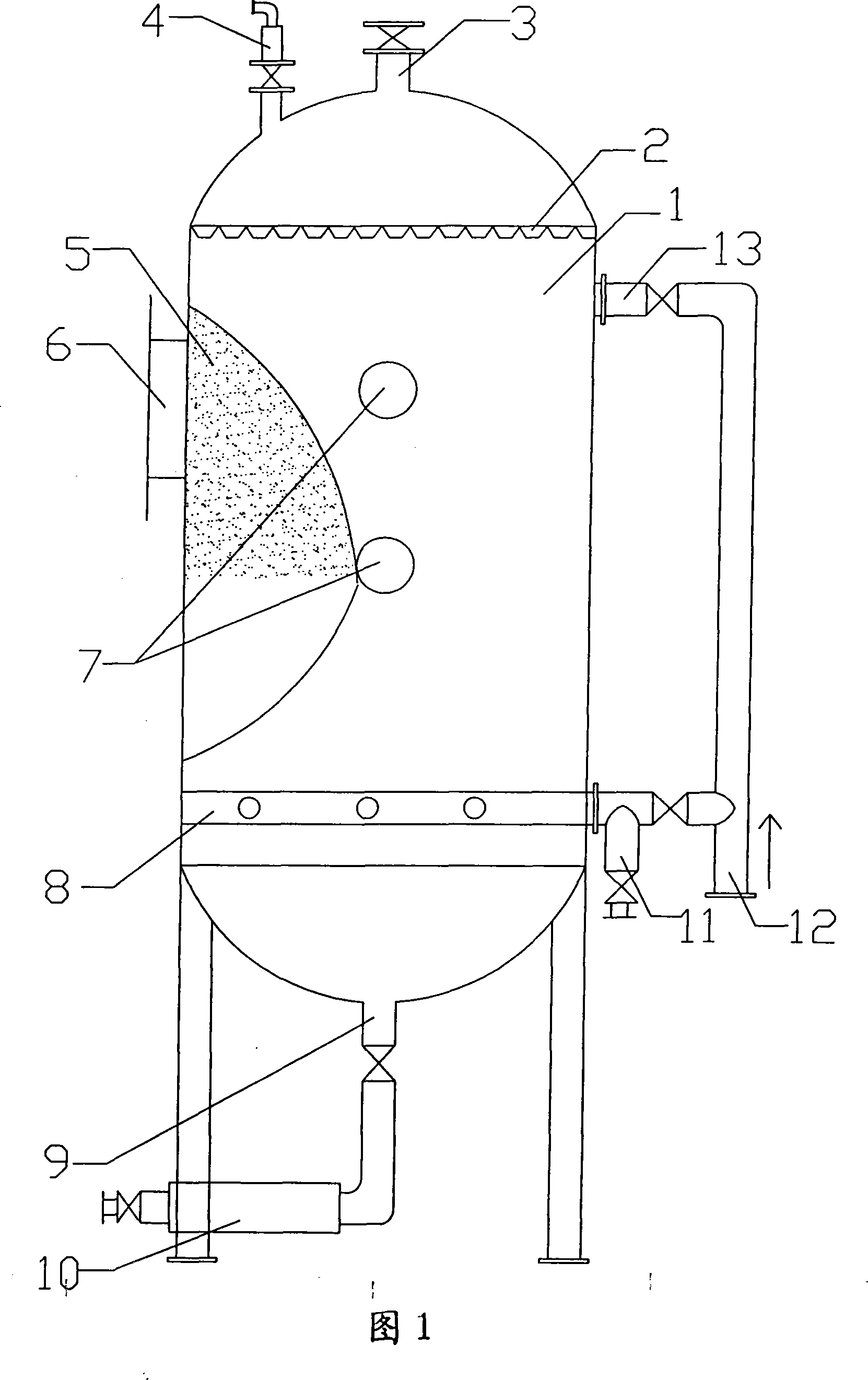

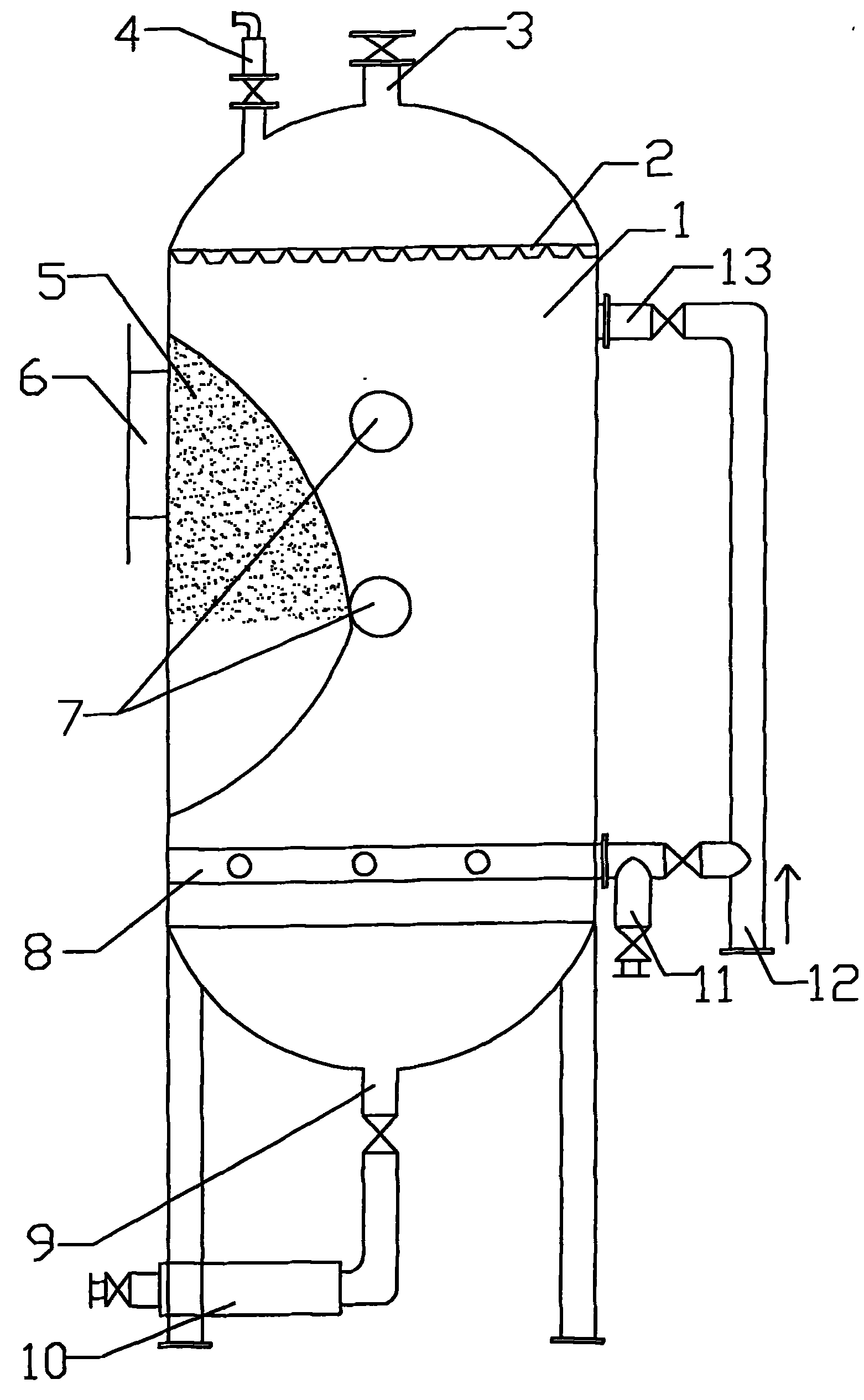

A floating filter technology, which is applied in the field of sewage treatment by filtration, upper filter sewage treatment, and sewage treatment, can solve the problems of difficult cleaning and treatment of filter materials, poor comprehensive benefits, and the inability to observe the specific status of sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 2

[0068] Carry out on the basis of specific implementation mode-implementation, a kind of use method of the floating up-filter type filter that can recoil cleaning dirt, according to following requirements:

[0069] (1), application equipment:

[0070] (1). ①. The application equipment is: apply the floating upper filter filter that can be recoiled and decontaminated as described in the first embodiment;

[0071] (1). ②. The floating filter material in the application equipment is as follows according to the weight ratio:

[0072] Polystyrene 91% is 91 kg,

[0073] Pentane blowing agent 8% is 8 kg,

[0074] 1% styrene free monomer is 1 kg;

[0075] (1). ③, the making of floating filter material in the application equipment: the described floating filter material is mixed, foamed and granulated after proportioning by weight according to the composition, and its particle size is 0.5 mm. Its specific gravity is less than 1; it is applied to the above-mentioned floating filter t...

specific Embodiment approach 3

[0090] Carry out according to specific embodiment two, just: floating type filter material is according to the proportioning by weight of following composition: polystyrene 95% is 95 kilograms, pentane foaming agent 4% is 4 kilograms, styrene free monomer 1 % is 1 kilogram; the floating filter material is mixed, foamed and granulated after proportioning by weight according to the components, and its particle size is 1.6 millimeters.

specific Embodiment approach 4

[0091] Carry out according to specific embodiment two, just: floating filter material is according to the proportioning by weight of following composition: polystyrene 93% is 93 kilograms, pentane blowing agent 6.9% is 6.9 kilograms, styrene free monomer 0.1 % is 0.1 kg; the floating filter material is mixed, foamed and granulated after proportioning by weight according to the components, and its particle size is 1.0 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com