Shipping tray for optical elements, and optical element shipped therein

A technology for optical components, transport pallets, applied in the field of optical components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

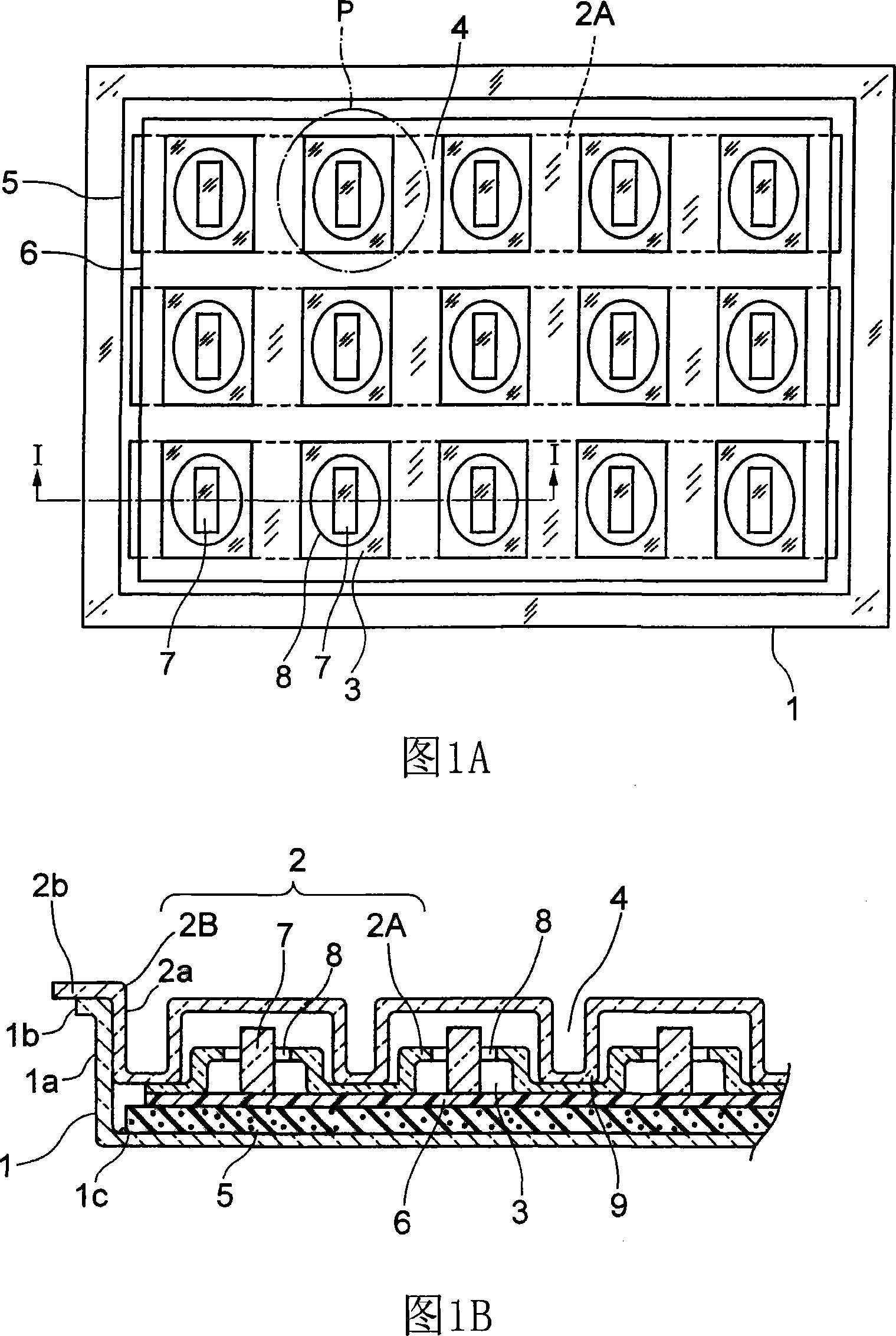

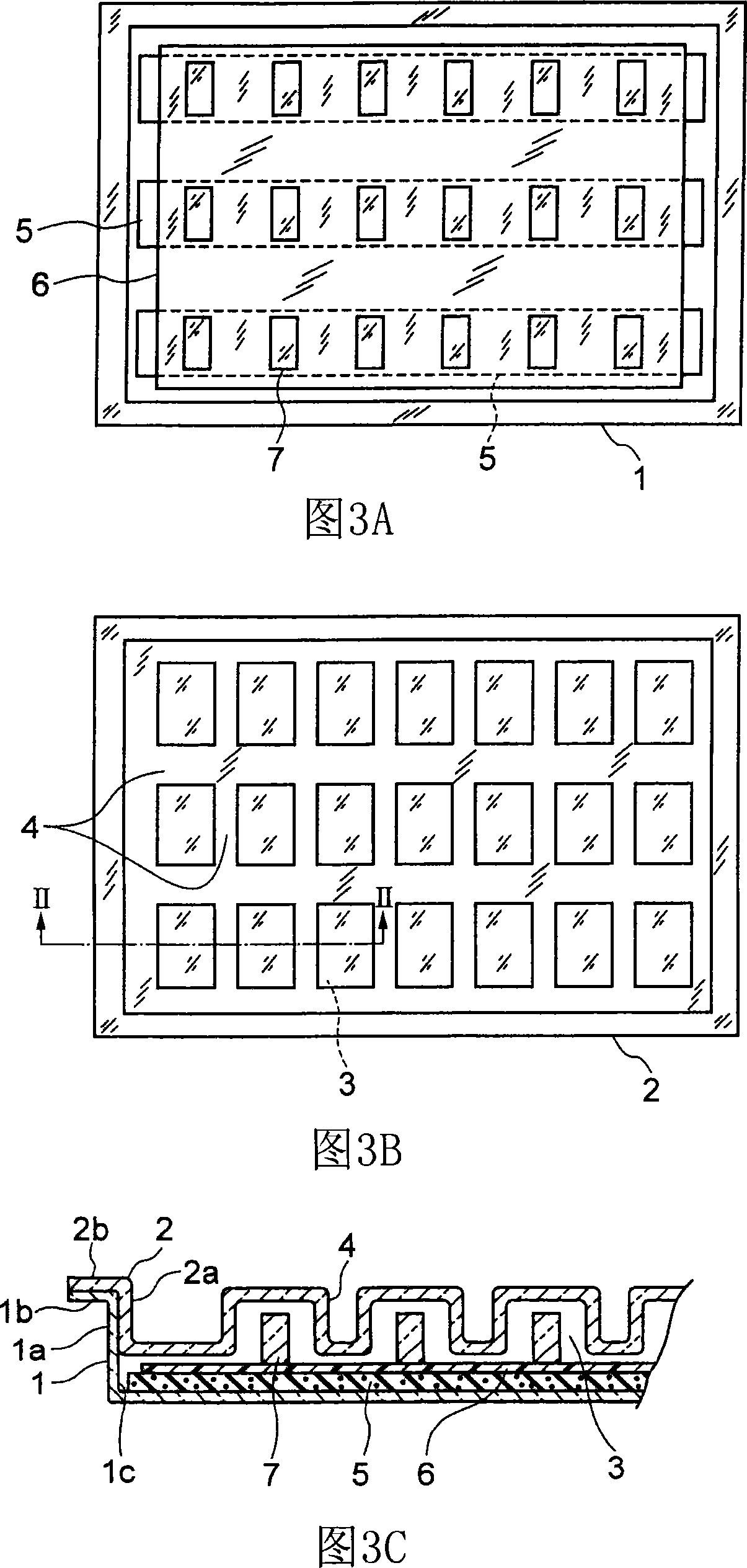

[0025] Fig. 1 shows an embodiment of the transport tray for optical elements according to the present invention, in which Fig. 1A is a plan view with the outer cover removed, and Fig. 1B is a partially enlarged cross-sectional view seen from the direction of arrow II in Fig. 1A . Please note that the same parts as those of the prior art are given the same reference numerals, and their description is simplified or omitted.

[0026] The transport tray for optical elements of the present invention is formed of a main container 1 and a cover 2, each of which is molded from a transparent plastic plate by using a mold (vacuum formation), as described previously. In this case, the cover 2 is composed of an inner cover 2A and an outer cover 2B.

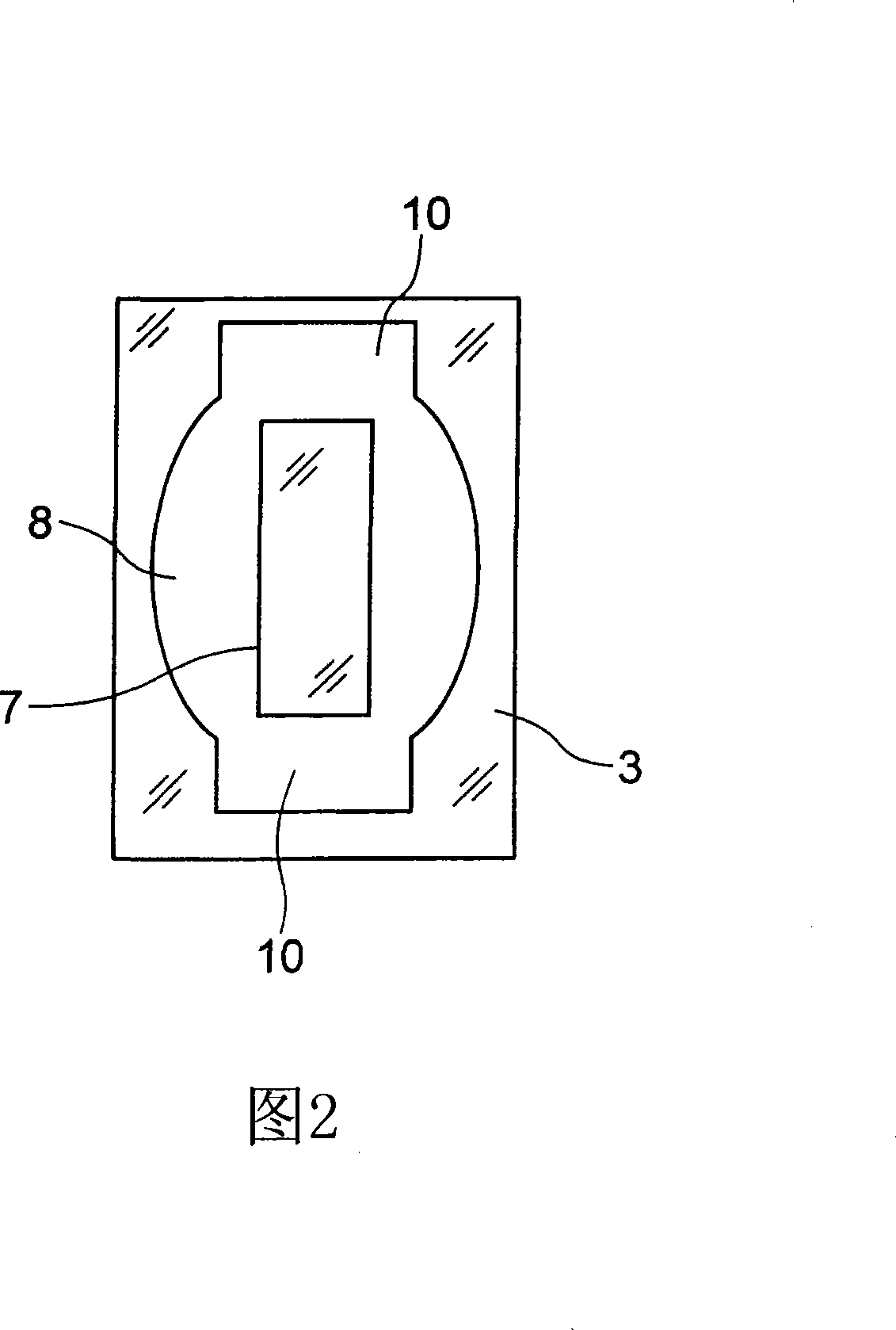

[0027] The inner cover 2A has a plurality of recesses 3 in a rectangular shape formed in the lateral and longitudinal directions by, for example, pressing, in which an oval (e.g., elliptical) hole portion 8 punched by a die is formed in the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com