Pulp forming packing base wad for washing machine bottom

A washing machine and pulp technology, which is applied in packaging, packaging food, machine containers, etc., can solve the problems of high mold cost, non-universal packing bottom pad of washing machine, and consumption of storage space, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

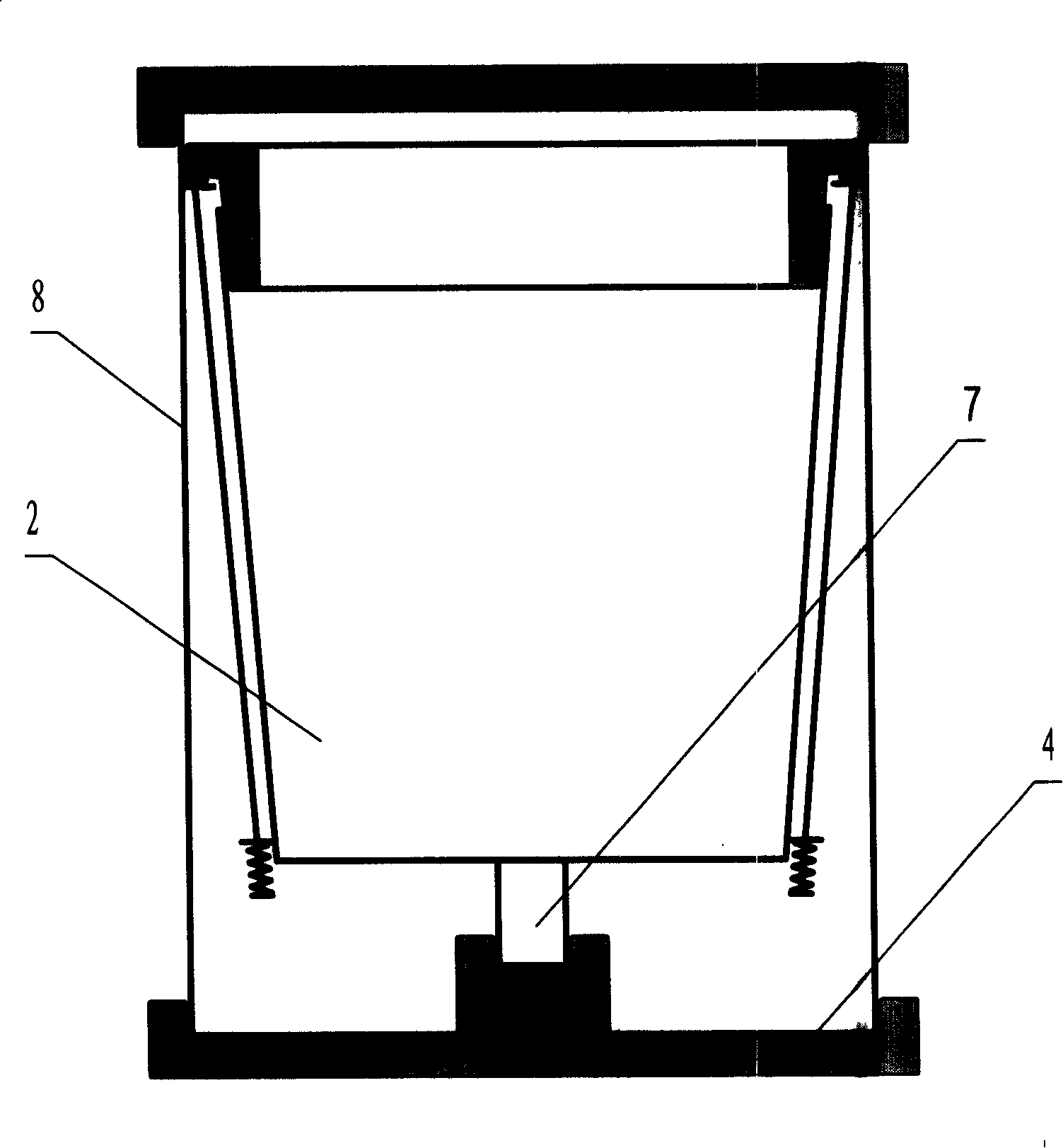

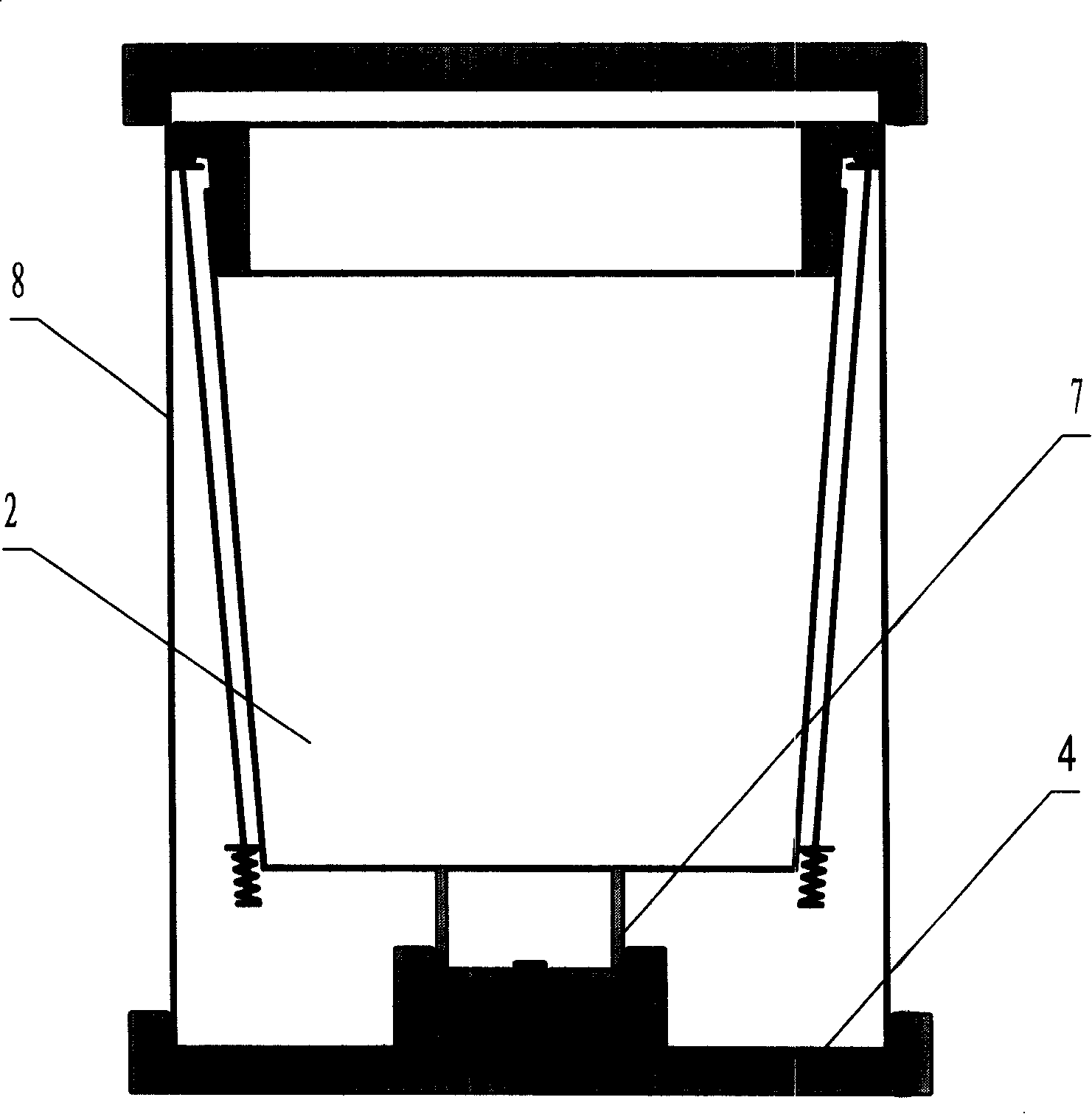

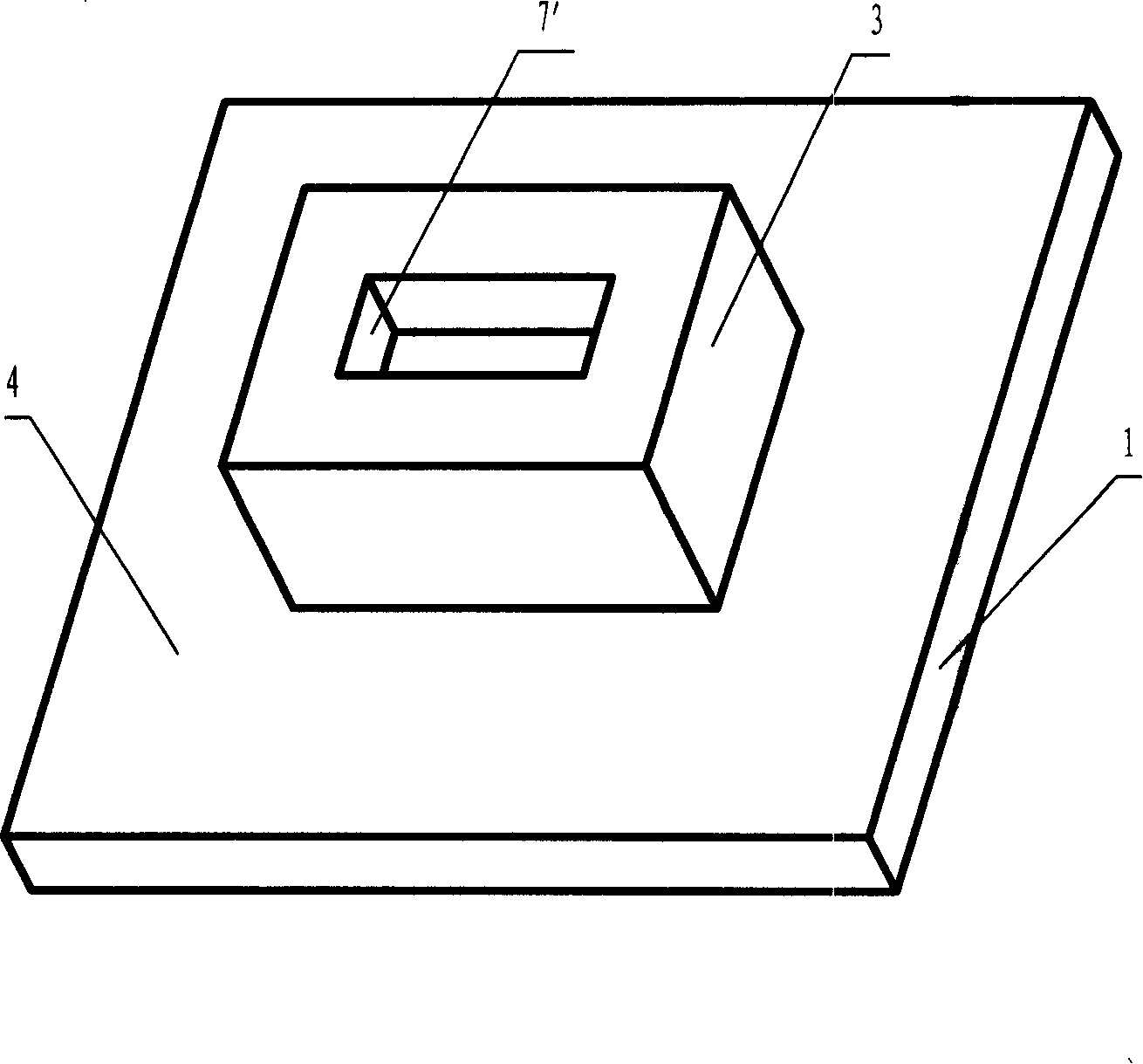

[0016] The packaging bottom cushion of the embodiment of the present invention is improved on the basis of the prior art packaging bottom cushion. The packaging base pad of prior art is as figure 1 , figure 2 , image 3 As shown, the packaging bottom pad 4 is integrally formed by supporting the support base 1 supporting the bottom of the outer casing 8 of the washing machine and the fixing seat 3 protruding from the upper surface of the support base 1 for fixing the inner tub parts of the washing machine.

[0017] The packaging bottom pad of the first embodiment of the present invention is as Figure 4 As shown, the prior art support base and the integrally formed packaging bottom pad of the fixing seat are divided into two parts, and become independent and mutually combined support base 5 and fixing seat 6 two parts. The support base 5 is provided with five protrusions 9 with a height of 20 mm upwards, and the lower end of the fixed base 6 is provided with five grooves 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com