Terrane stress simulation clamping device

A clamping device and stress technology, applied in the field of rock stress simulation clamping devices, can solve problems such as failure to fully simulate gas-bearing coal seams, failure of the device to simulate, and failure to simulate local stress concentration in the mining face, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

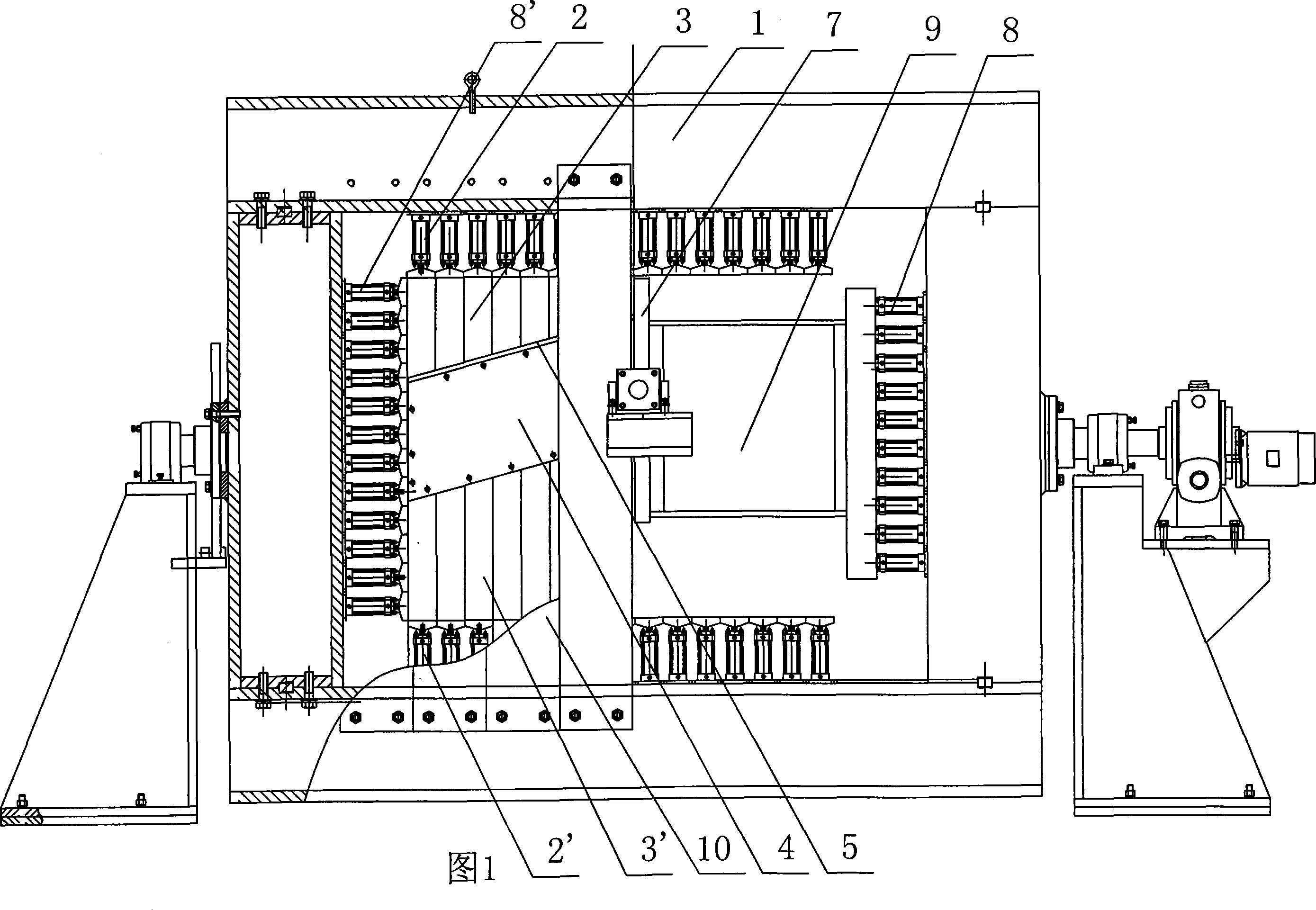

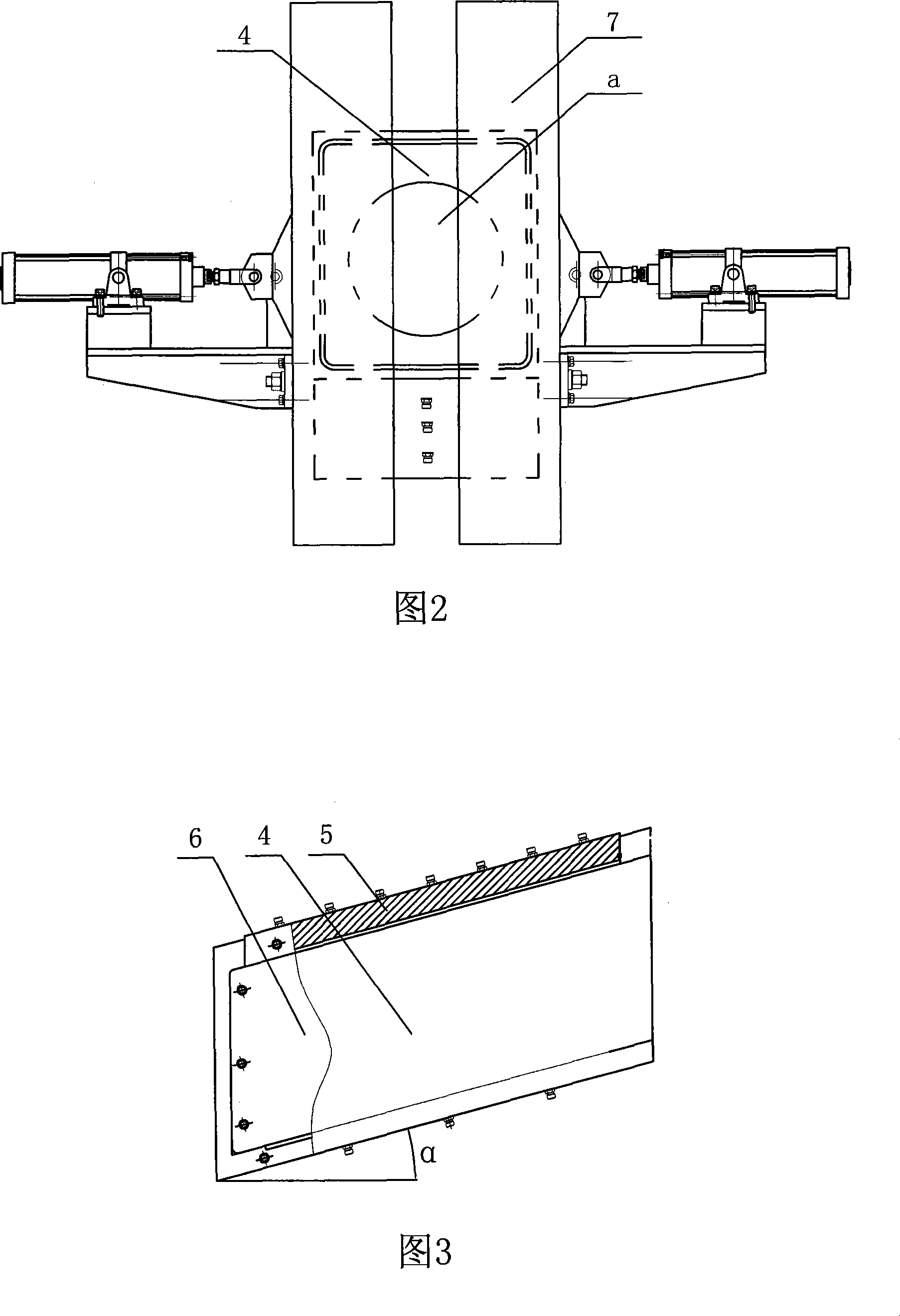

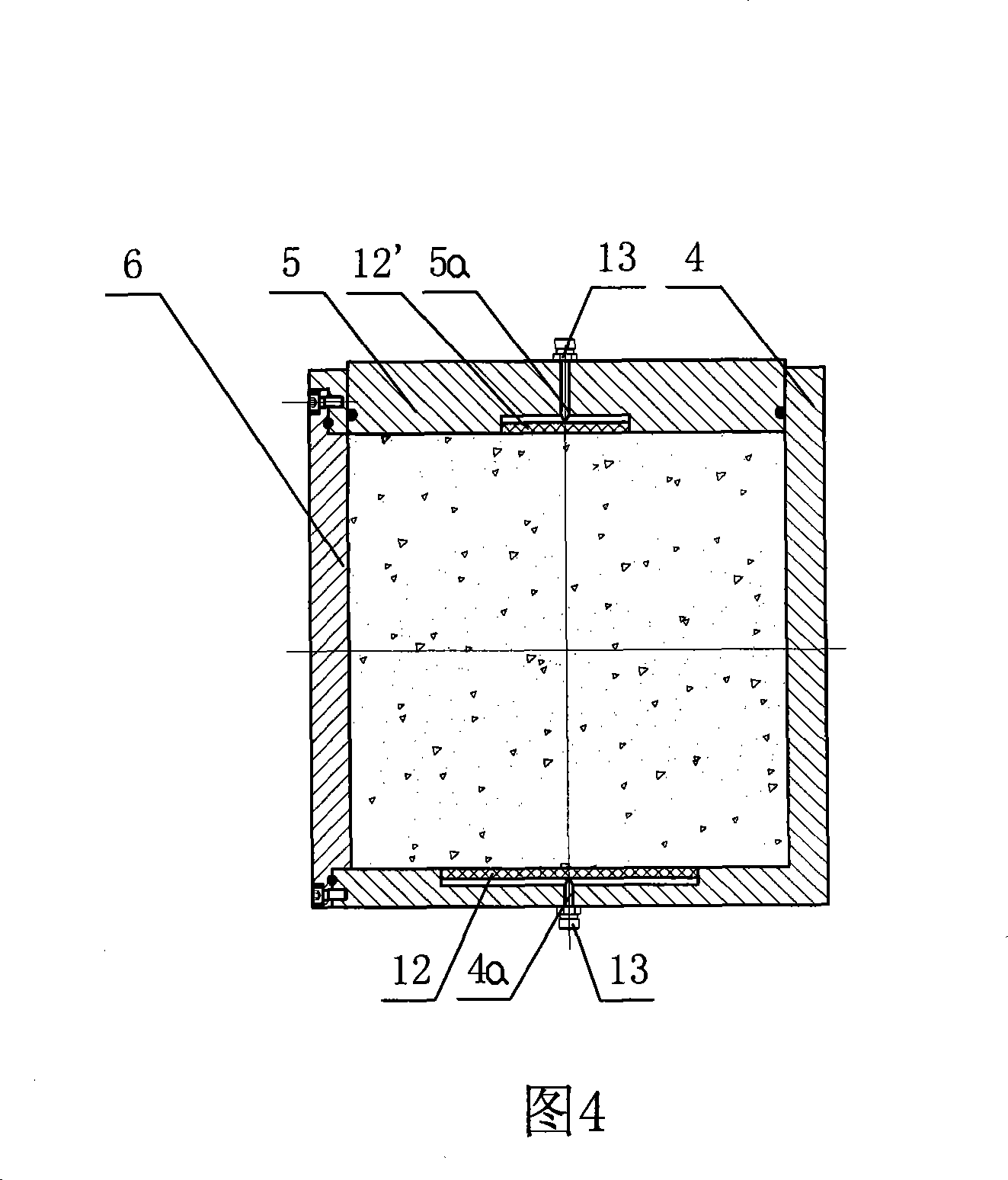

[0030] As shown in Figures 1 and 2: a rock formation stress simulation clamping device is provided with a rectangular reaction force frame 1, and at least one row of hydraulic cylinders are fixed on the inner walls of the two transverse sides of the reaction force frame 1, wherein the upper and lower The upper and lower hydraulic cylinders 2, 2' push rods on the horizontal side are respectively fixed with upper and lower pressing blocks 3, 3', and the upper and lower hydraulic cylinders 2, 2' respectively push the upper and lower pressing blocks 3, 3 'points to the middle of the reaction force frame 1, a pressure test box 4 is connected between the upper and lower pressure blocks 3, 3', the upper end of the pressure test box 4 is open, and a movable pressure plate 5 is installed in close fit, so The above-mentioned upper briquetting b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com