Piercing mandrel of automatic dotter and automatically dotting method

A punch, automatic technology, used in clothing, footwear, tools for sewing clothes, etc., to ensure one-time success, smooth surface, and ensure accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

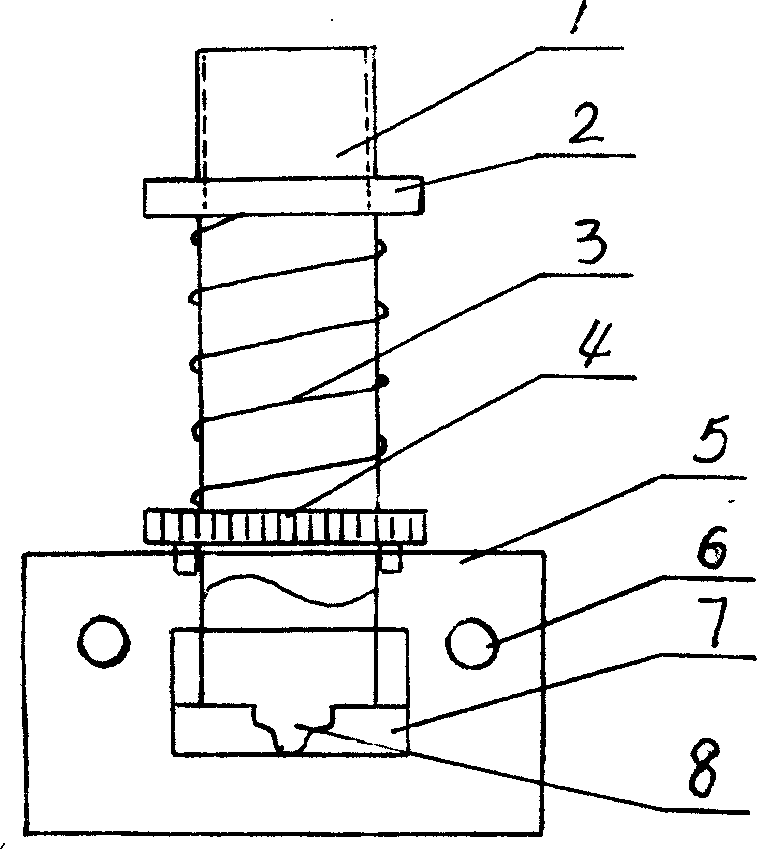

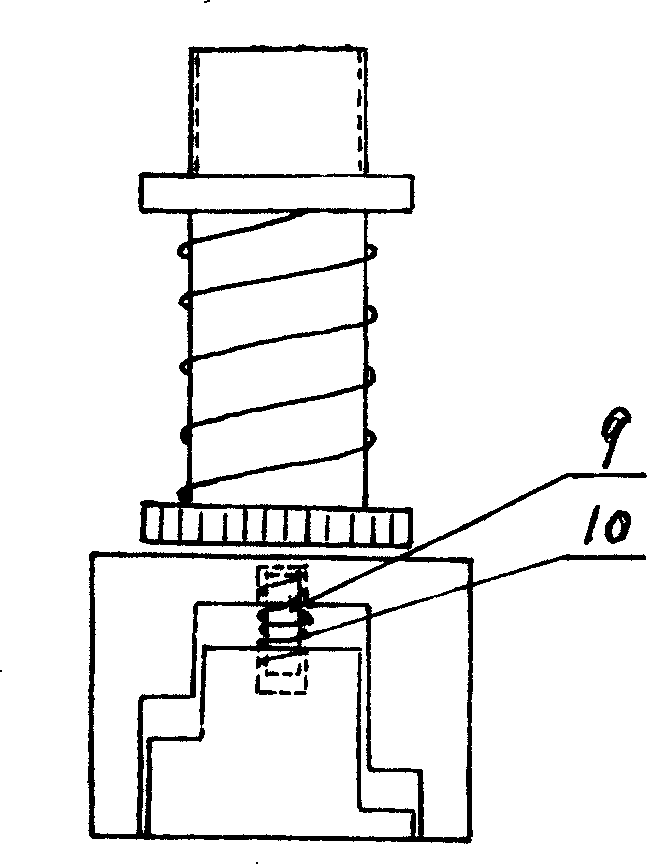

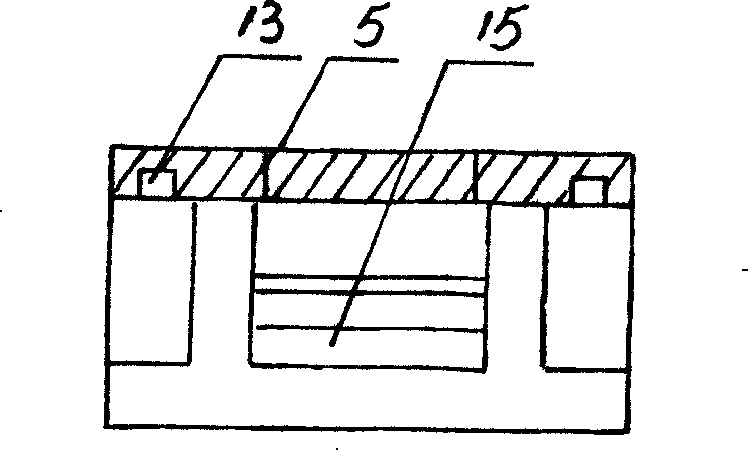

[0012] Embodiment 1: with reference to attached Figure 1~4 . The automatic buckle punch includes a punch base. The structure of the punch base has been disclosed in the background art, and its manufacturing process is a prior art, so it will not be described here. The punch jacket 5 has a groove structure and is made by a wire cutting machine. The two punch chucks 7 are made by a wire cutting machine and are located in the groove of the punch jacket 5. The two punch clips located in the groove of the punch jacket 5 are The head 7 adopts the pin shaft 6 to be pinned to the two side plates of the punch jacket 5 respectively and the two punch chucks 7 rotate around the pin shaft 6. The upper end of the punch chuck is in conflict with the inner end surface of the punch jacket, which is convenient for the punch chuck to be opened downward. The ends of the chucks 7 of the two punches are opposite to the inner end surface of the punch jacket 5 with a guide column hole 13, the guid...

Embodiment 2

[0013] Embodiment 2: The automatic buckle method of the punch of the automatic buckle machine, the lower buckle is located on the punch base, the material to be buckled is located on the lower buckle, and the bottom of the jacket has been flattened and punched when the punch moves down to the workpiece The surface of the material makes the surface smooth when punching and buckling, and there will be no folding and shrinking. The buckle enters the punching socket formed by the two punch chucks through the button hole on the back of the punch jacket, and the piston in the cylinder drives the punching When the rod moves downward, the punch located at the lower end of the punch rod passes through the hole of the make-up button, and at the same time directly impacts the make-up and the punching socket formed by the two punch chucks, the punching socket is forced to open automatically, and the upper button is automatically opened. The buckle falls steadily on the material to be punch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com