Equipotential operating curve ladder

A technology of equipotential operation, applied to ladders, overhead lines/cable equipment, buildings, etc., can solve the problems that the combined gap cannot meet the requirements and cannot perform equipotential operations, etc., and achieve the effect of compact wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

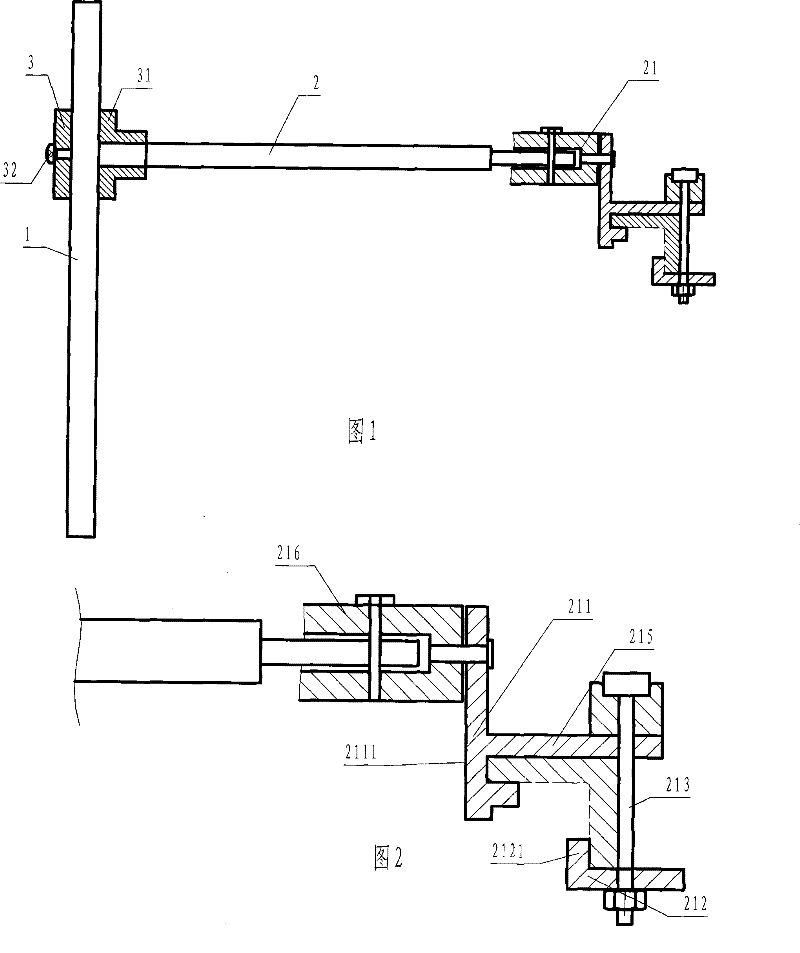

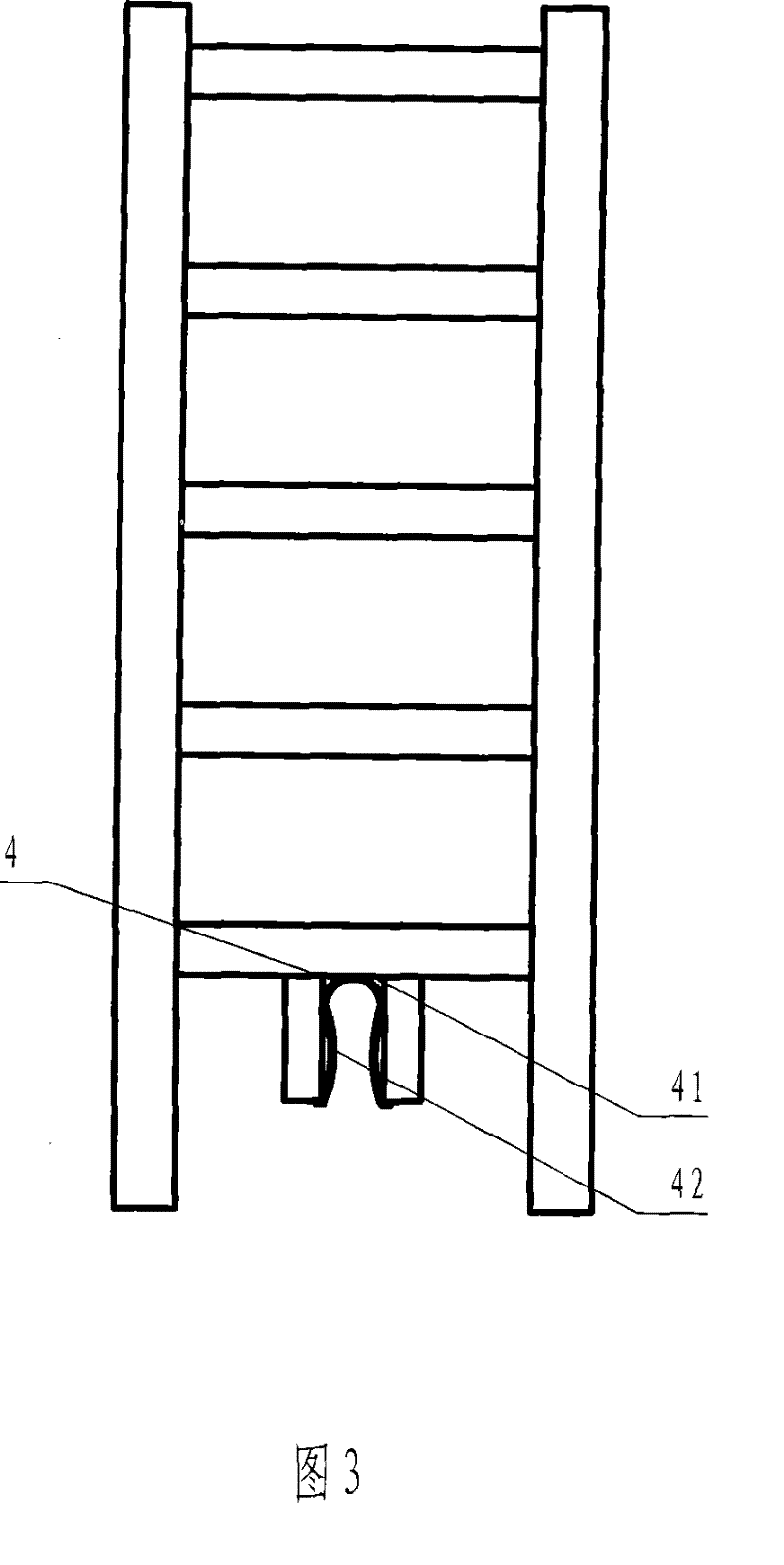

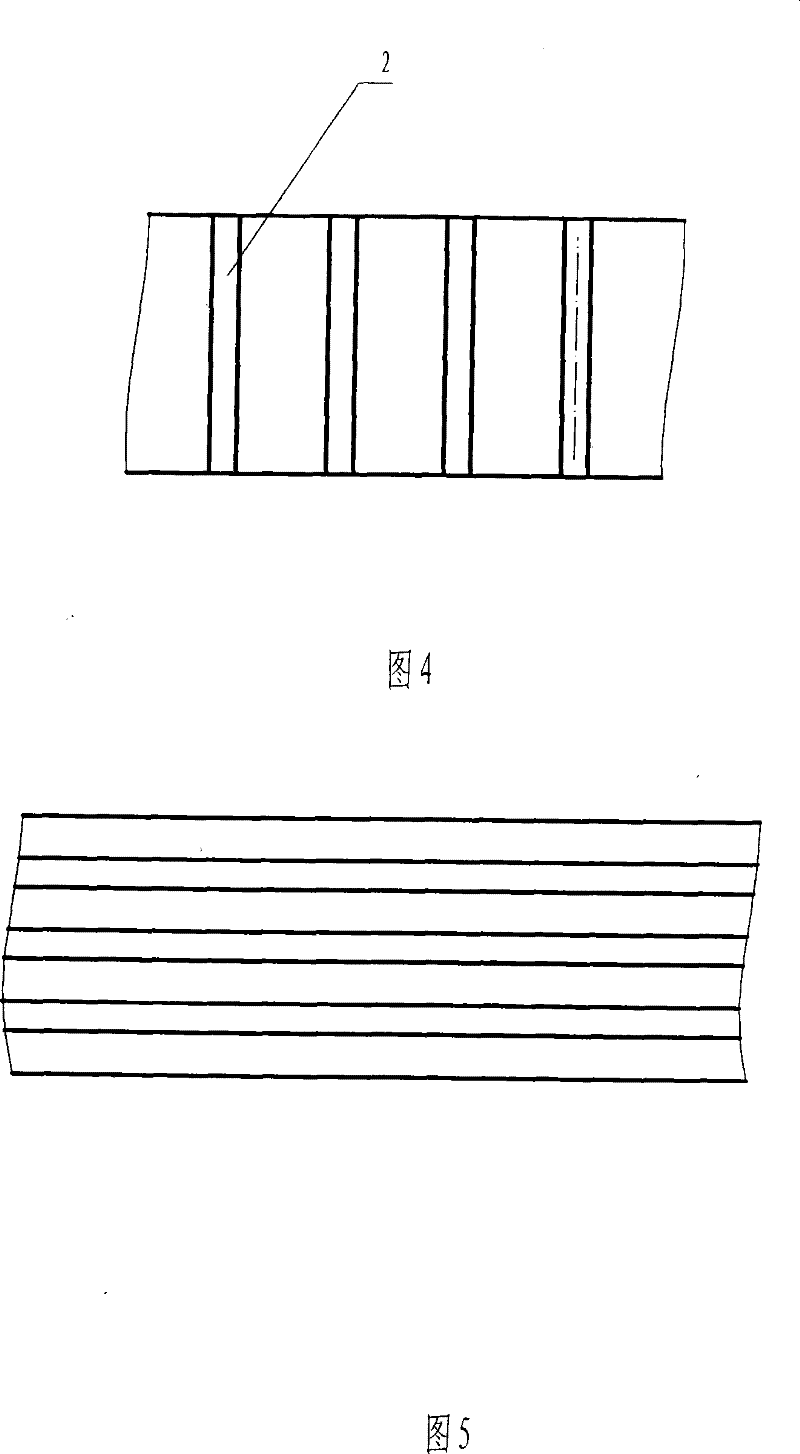

[0045] a kind of like Figure 1-4 The curved ladder for equipotential work shown includes a straight ladder 1 and a horizontal frame 2. The straight ladder and the horizontal frame are both made of insulating materials. The two are intersected and connected. The cross-arm connecting piece 21 is fastened to the cross-arm angle steel. The cross arm connector 21 includes a main body 211, a pressure plate 212 and a fastening bolt 213, the bottom of the main body 2111 is connected to the end of the cross frame, and the bottom of the side of the main body vertical plate 215 has a groove into which the end of the cross arm angle steel wing plate can be embedded. 2151, the fastening bolts of the horizontal frame above the main body vertical plate connect the main body vertical plate and the pressure plate, and the lower end of the pressure plate has a bending head 2121 that can be connected with the hook of the other wing plate of the cross arm angle steel. The connection mode betwee...

Embodiment 2

[0048]The structure of embodiment 2 is basically the same as that of embodiment 1, and its horizontal frame part is a framework in which a plurality of rods with the same length are distributed in parallel and at intervals and fixedly connected into one. The position adjustment mechanism between the horizontal frame and the vertical ladder is that connecting holes are distributed on the vertical ladder at intervals along its length direction, and a kind of bolt passes through the holes and the holes on the horizontal frame to fasten the horizontal frame and the vertical ladder. The supporting mechanism of the lower section of the straight ladder is located at the bottom end of the side bar of the straight ladder.

[0049] The parts not described in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com