Horizontal tube falling-film evaporator with flow guiding device and secondary liquid-dispensing device

A technology of falling film evaporator and diversion device, which is applied in the direction of horizontal tube evaporator, etc., can solve the problems of increasing steam energy loss, unfavorable promotion, and reduced heat exchange effect, so as to improve heat exchange efficiency, avoid splashing, and liquid flow stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

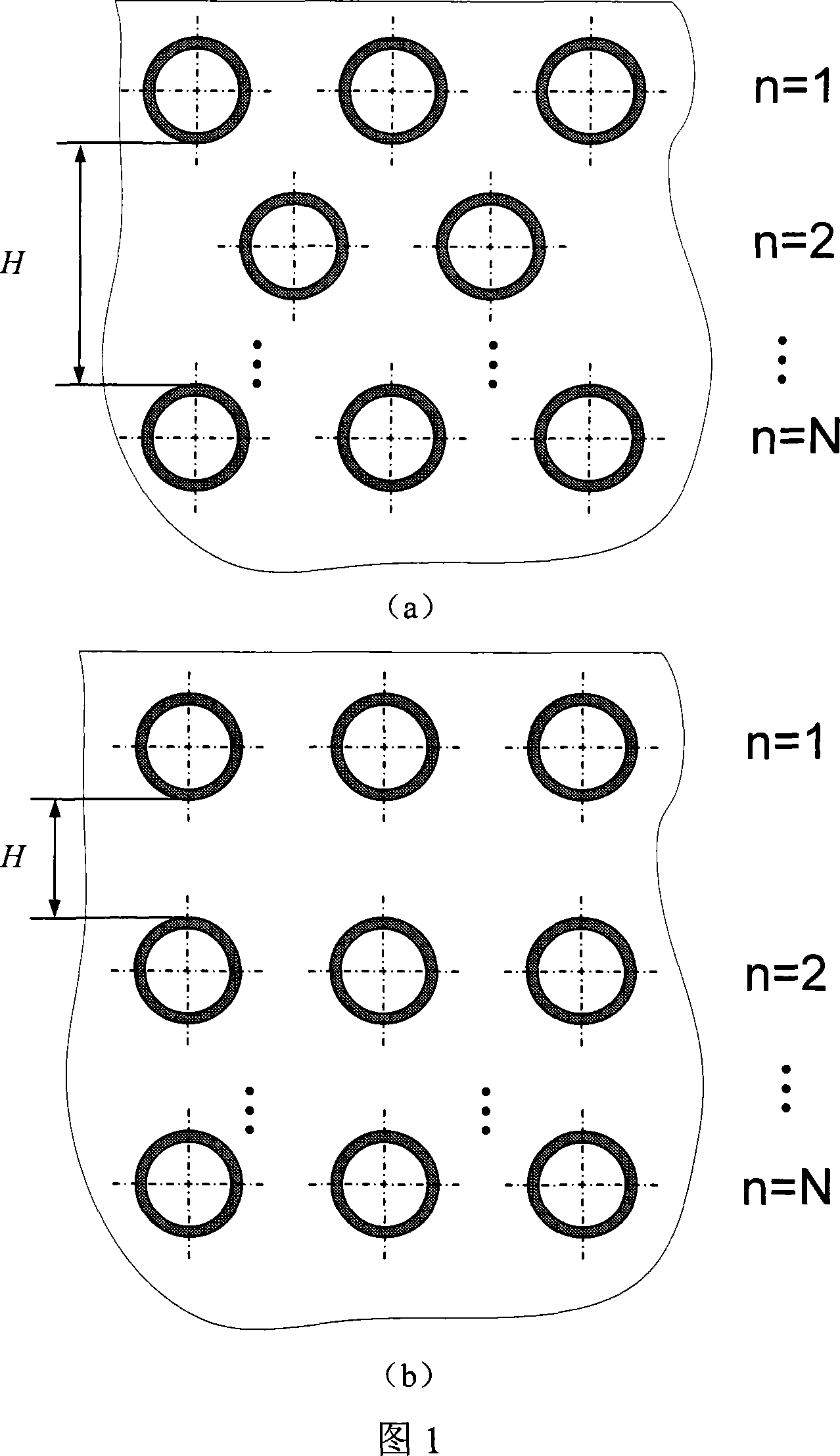

[0027] The tube bundle arrangement form of the horizontal tube falling film evaporator can be selected from the tube bundle arrangement form of the traditional horizontal tube falling film evaporator, that is, rectangular arrangement, triangular arrangement, etc., as shown in Figure 1.

[0028] 1. Diversion device

[0029] Since different forms of diversion devices are set for different flow state stages, it is necessary to determine in advance the pipe row intervals occupied by the three flow states (sheet flow, columnar flow, and droplet flow). The pipe row interval occupied by each flow state can be determined by calculating the total flow rate of the liquid working medium above the liquid distributor. Accordingly, the corresponding continuous sheet-shaped flow guide device, zigzag sheet-shaped flow guide device and linear flow guide device are arranged. The specific form of each diversion device is as follows:

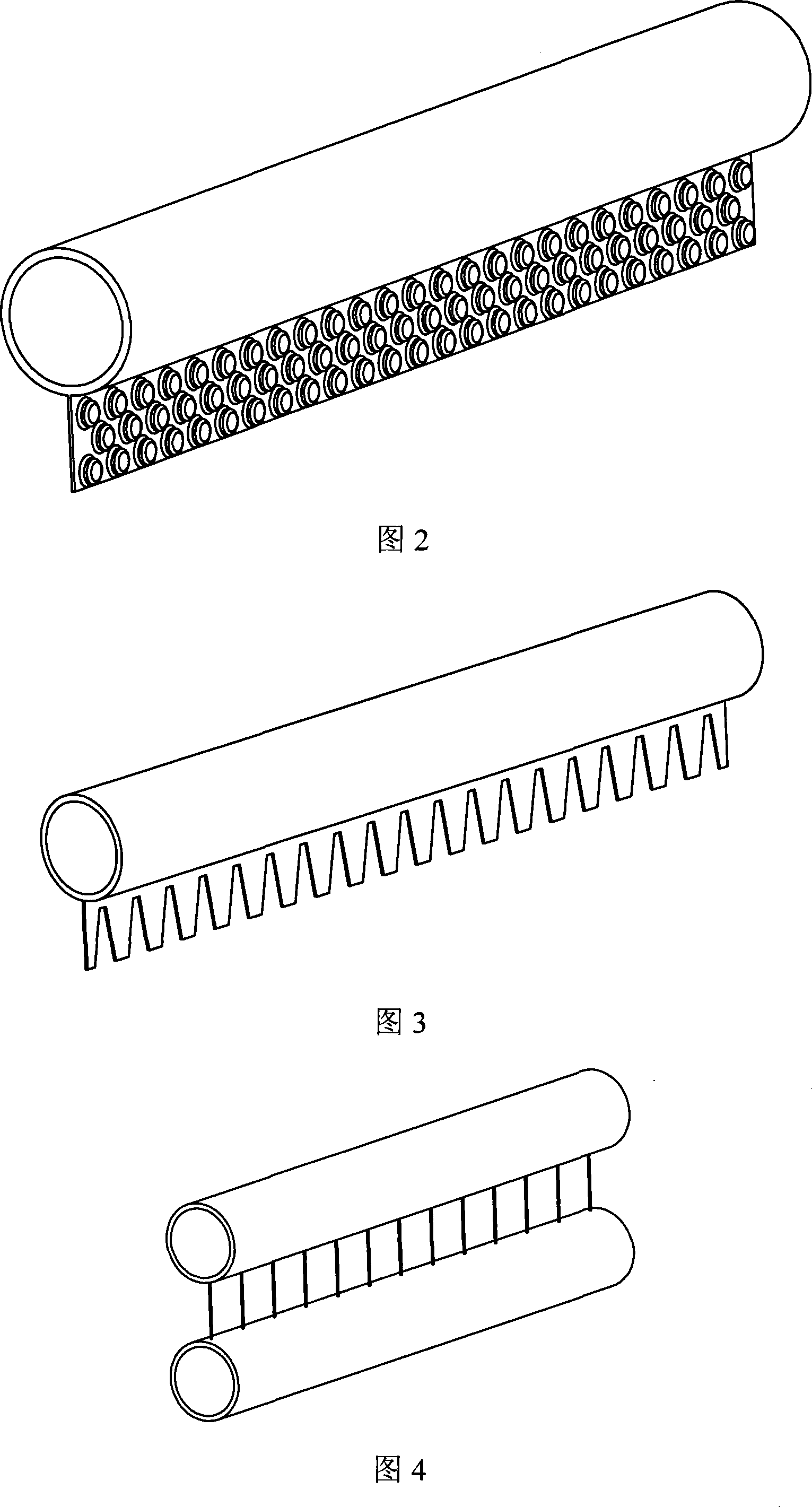

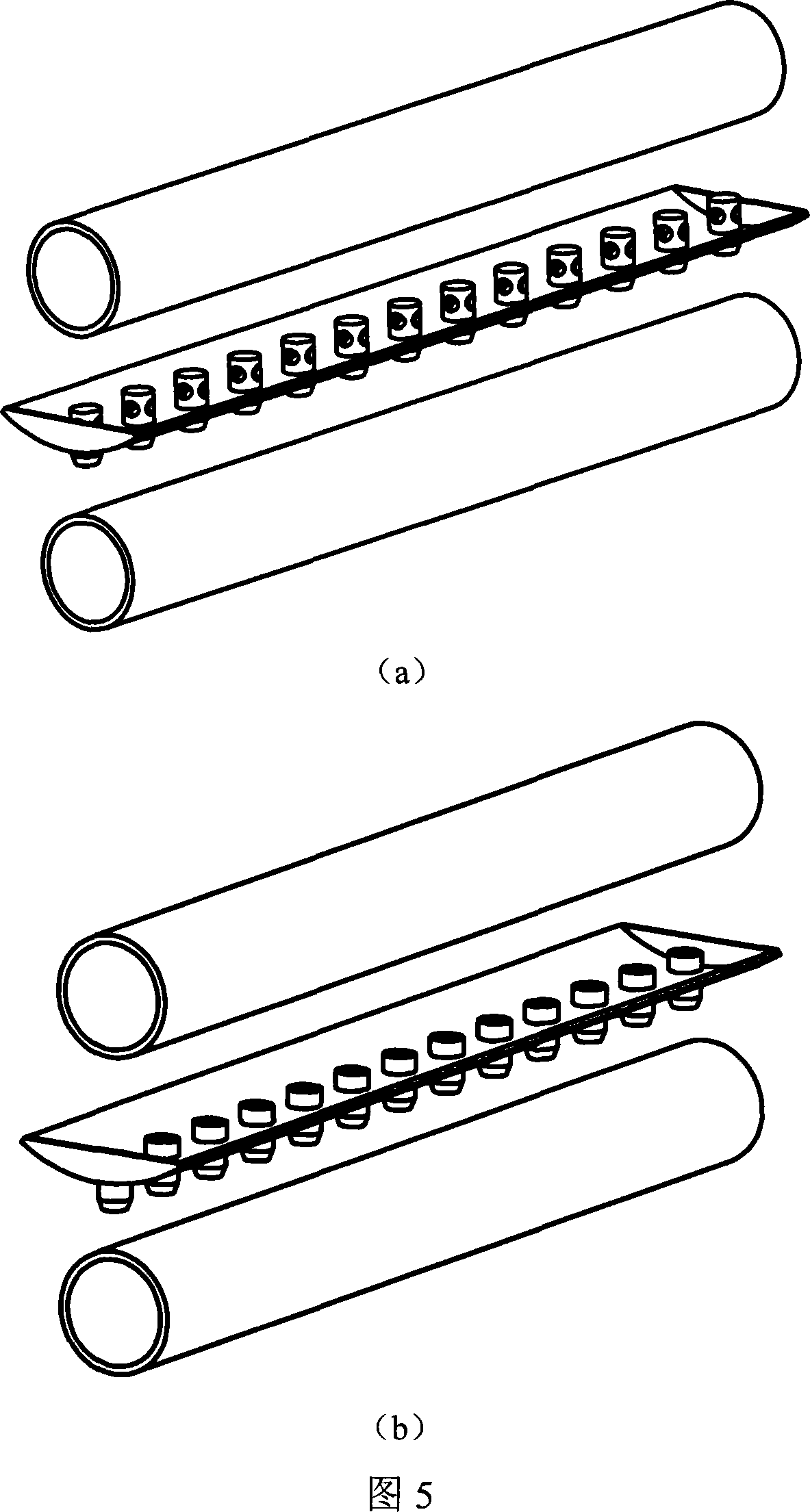

[0030] 1. Continuous sheet diversion device

[0031] As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com