Garden waterpipe winding machine and its control method

A technology for winding pipes and water pipes, which is applied in the directions of pipes/pipe joints/fittings, mechanical equipment, pipe laying and maintenance, etc. It can solve the problems of inconvenient storage of the pipe winding machine in winter, avoid adverse effects, have a simple structure, and solve the problem of inconvenience in opening. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

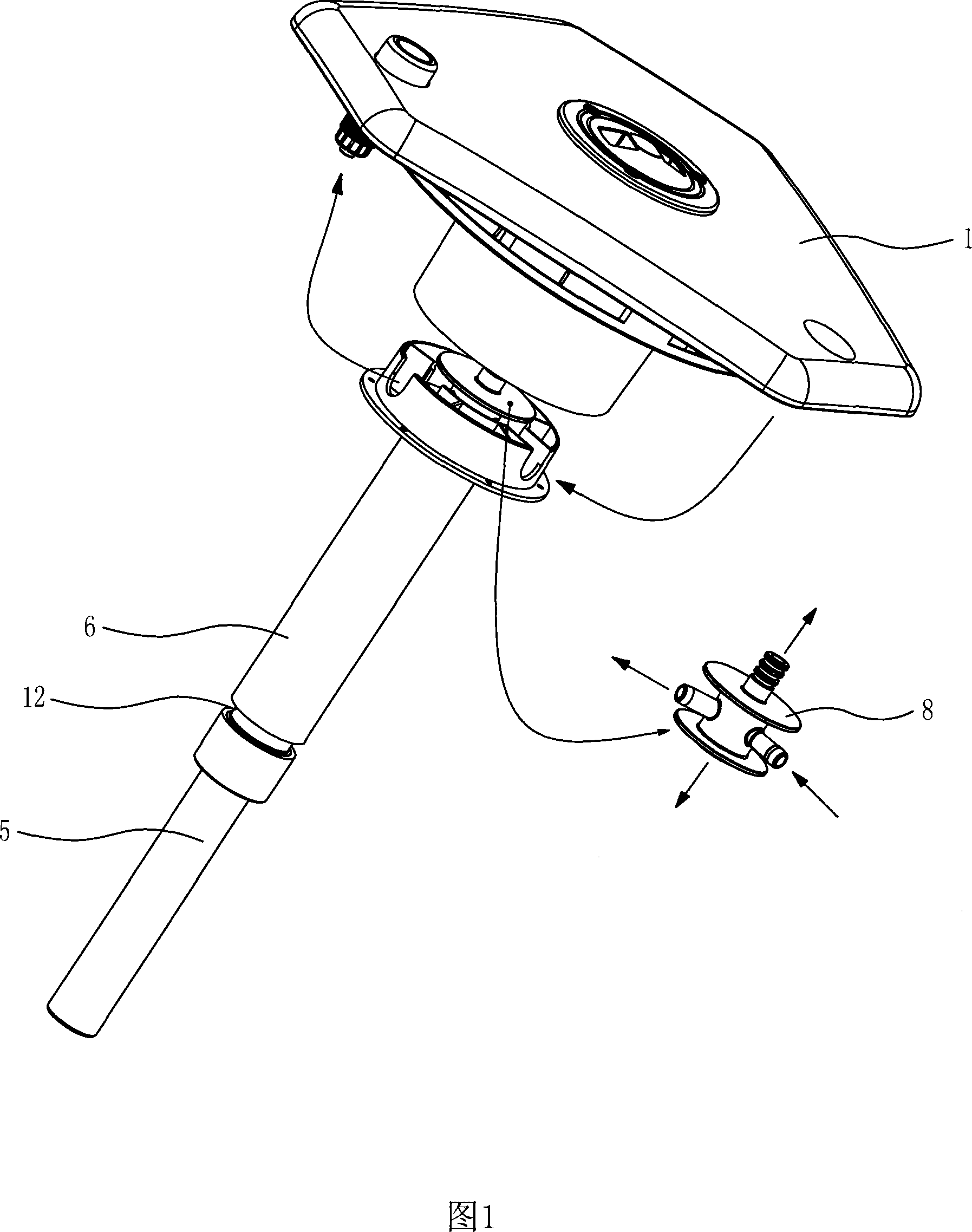

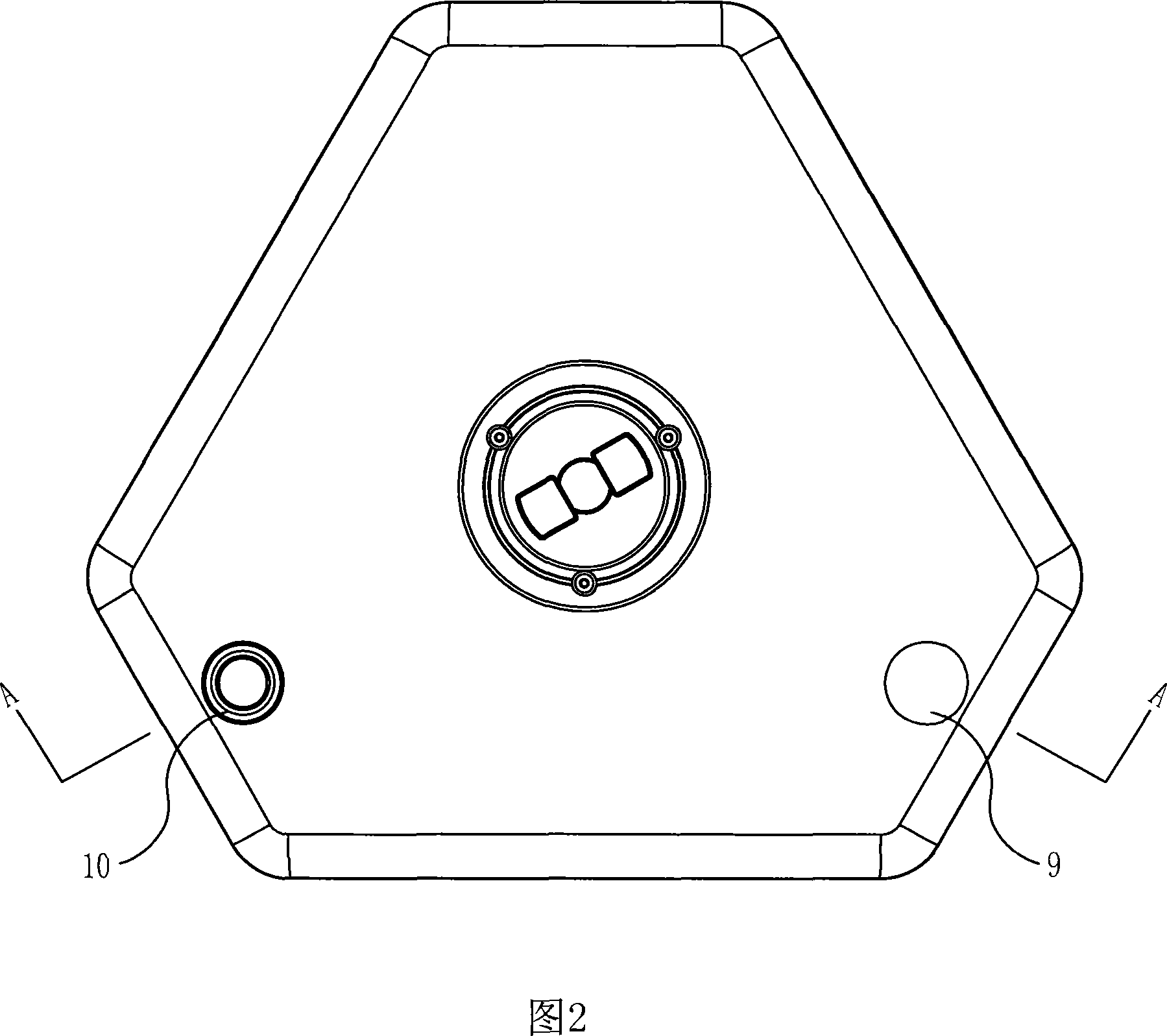

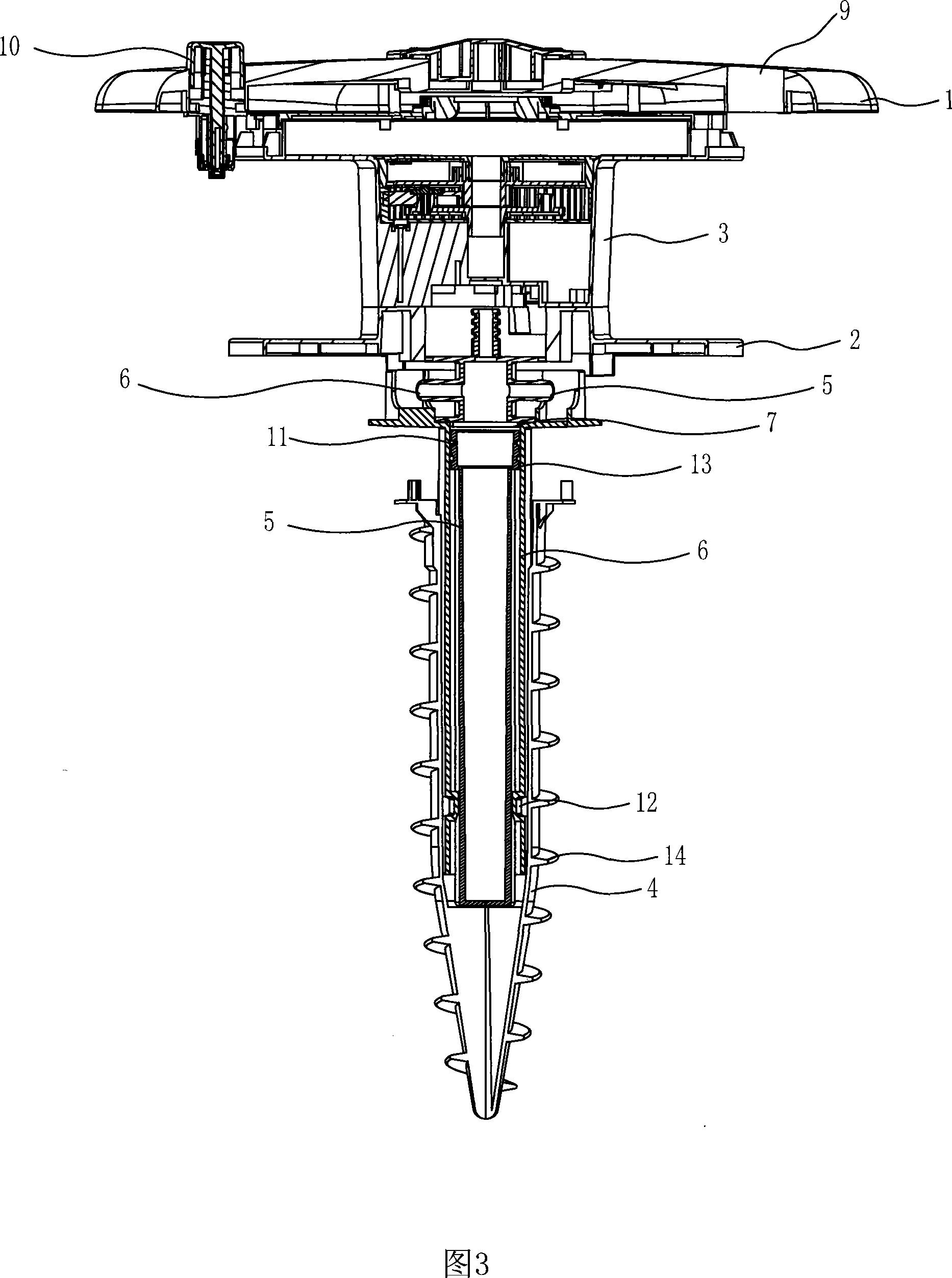

[0018] Embodiment 1: Referring to accompanying drawings 1 to 3, a garden hose winding machine includes a winding coil assembly, a water supply hose wound on the winding coil assembly, and a positioning installation assembly. The coil assembly is mainly composed of the top cover 1 of the coil coil, the base 2 of the coil coil, the coil shaft 3 arranged between the roof and the base, and the recovery speed limiting device. The positioning and installation assembly includes a shell buried in the soil And the fixed rod 4 at the lower end of the housing, the fixed rod is a hollow structure, which contains a positioning rod 5 and a sliding rod 6 sleeved on the positioning rod and slidingly connected with it. A sealing structure is provided between the sliding rod 6 and the positioning rod 5, so that a pressure chamber 7 is formed between the lower end of the coiling coil base, the sliding rod and the positioning rod, and a cross 8 is provided on the coiling coil base, and each passag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com