Air compressor piston body structure improvement

A technology for air compressors and piston bodies, which is applied in the field of air compressors and can solve problems such as damage, wrinkles at the connection between the reed and the valve head, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

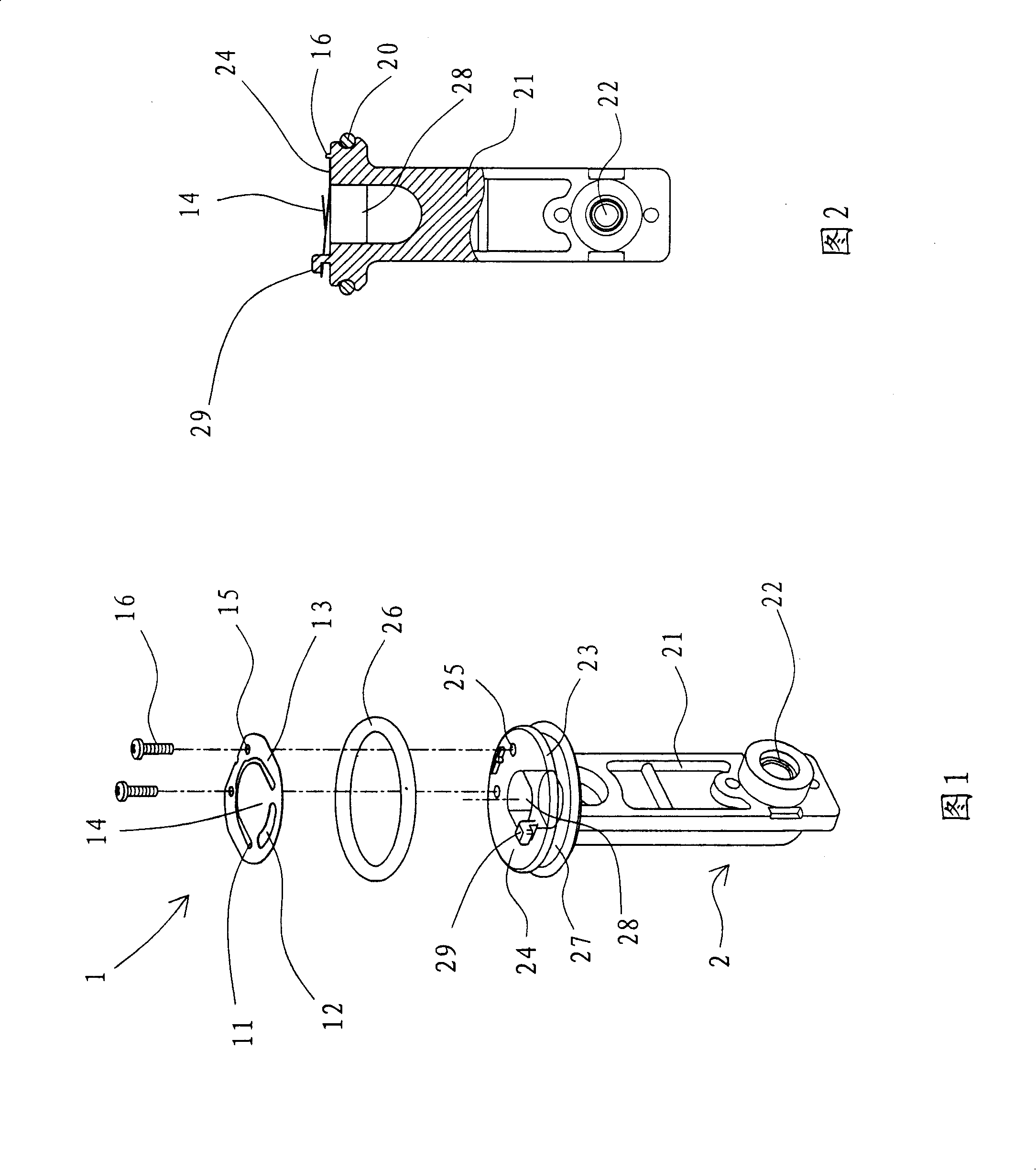

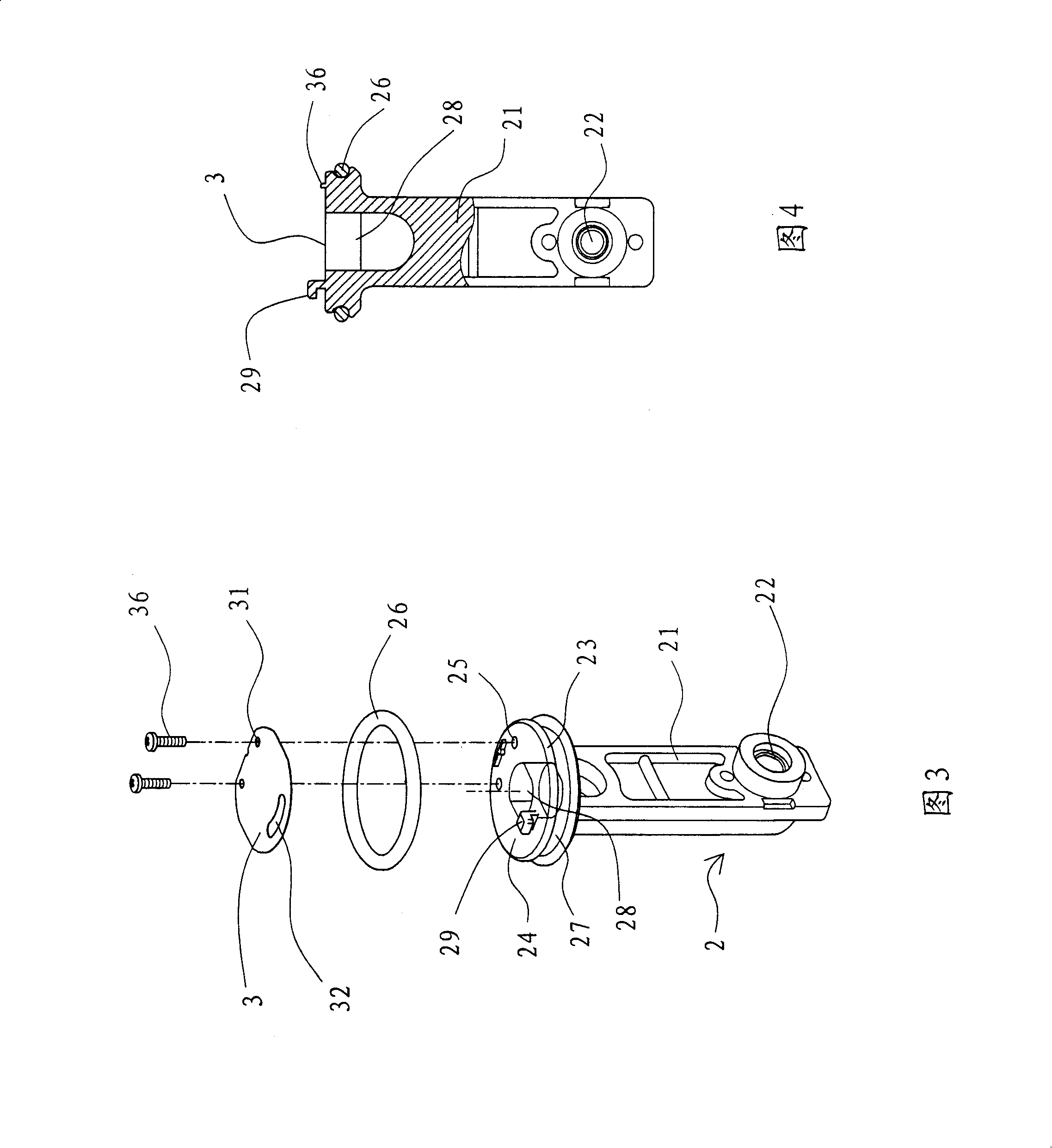

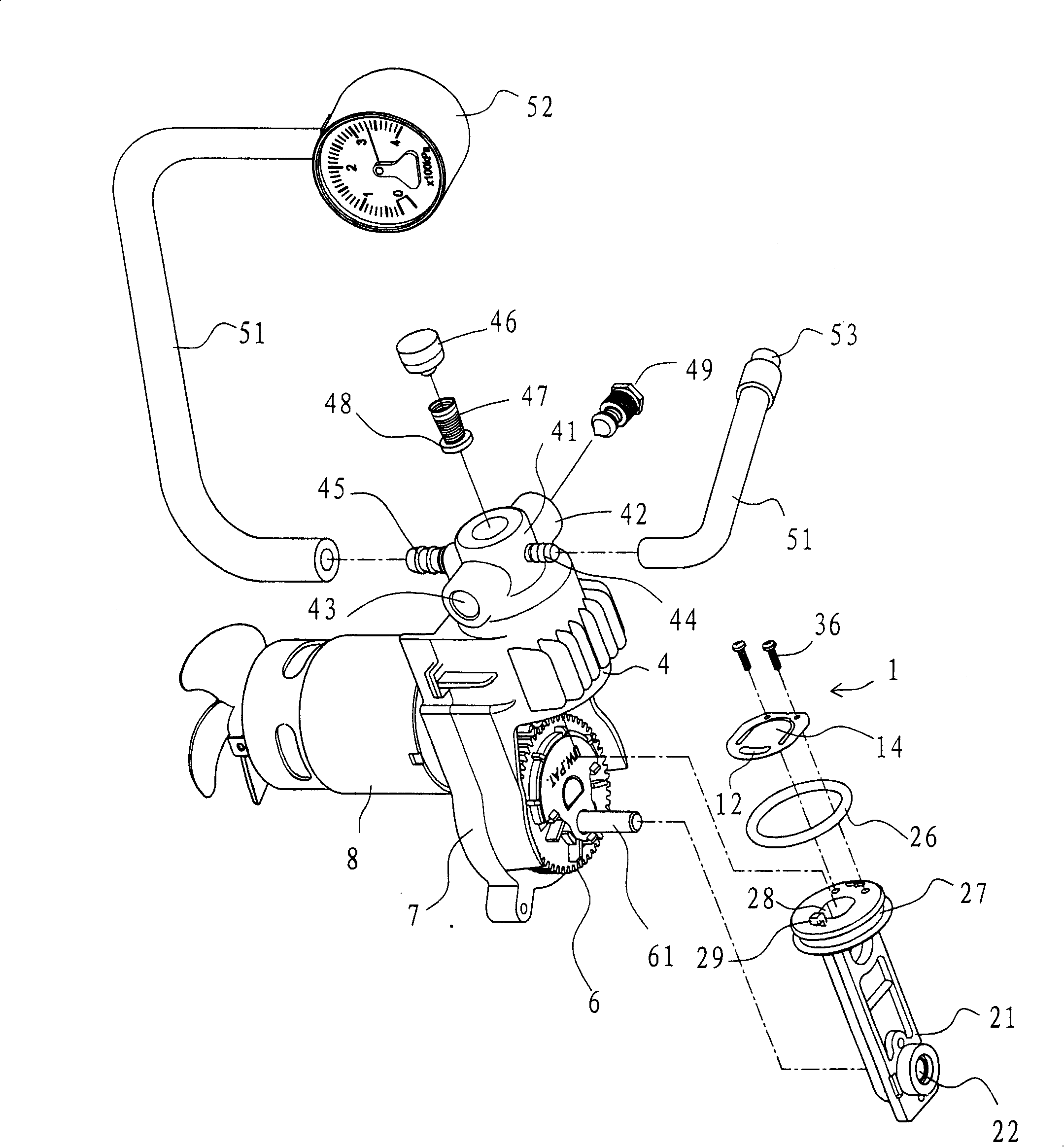

[0026] The present invention is an improvement in the structure of the piston body 2 . Please refer to FIG. 1 , the present invention includes a piston body 2 and a reed 1 . Cut a hollow circular arc-shaped inner hollow area 11 in the reed 2, the peripheral part of the inner hollow area 11 is an outer ring area 13, and the inner peripheral part of the inner hollow area 11 is an inner disc 14, and the inner circle of the inner hollow area 11 A stop groove 12 is hollowed out at the notch, and two positioning holes 15 are set at the opposite ends of the stop groove 12 on the reed 1 .

[0027] One piston body 2, the upper end is provided with valve head 23, and valve head 23 extends piston rod 21, and piston rod 21 lower end is provided with a shaft hole 22; Above the valve head 23; the top surface 24 of the valve head 23 is provided with two screw holes 25, which can be fixed in the screw holes 25 through the positioning holes 15 of the aforementioned reed 1 with bolts 16; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com