Special-shaped flattened rayon spinning machine

A rayon and spinning machine technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of inability to produce special-shaped flat, non-twisted, large-denier rayon, etc., to achieve large denier and use Convenience and large filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

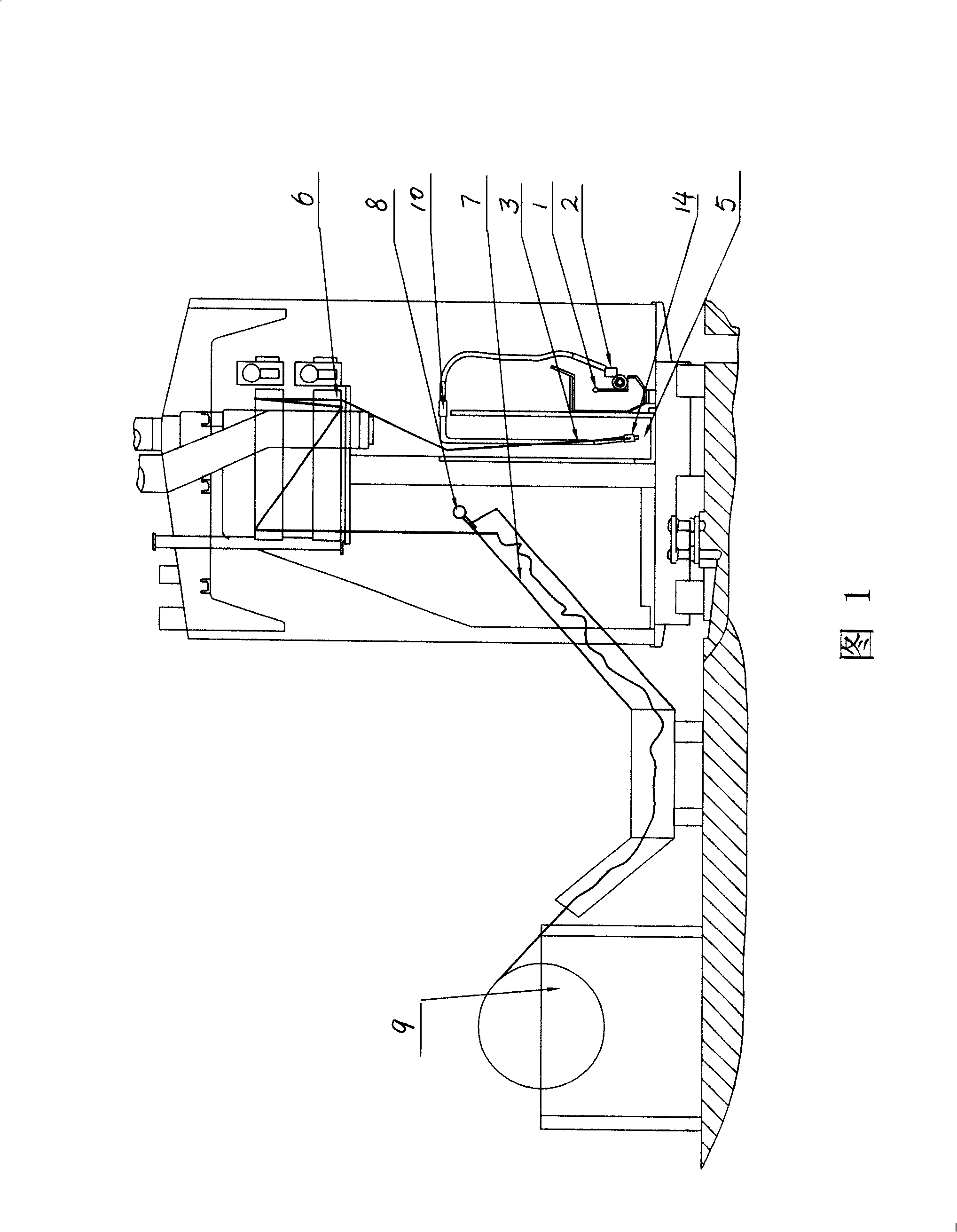

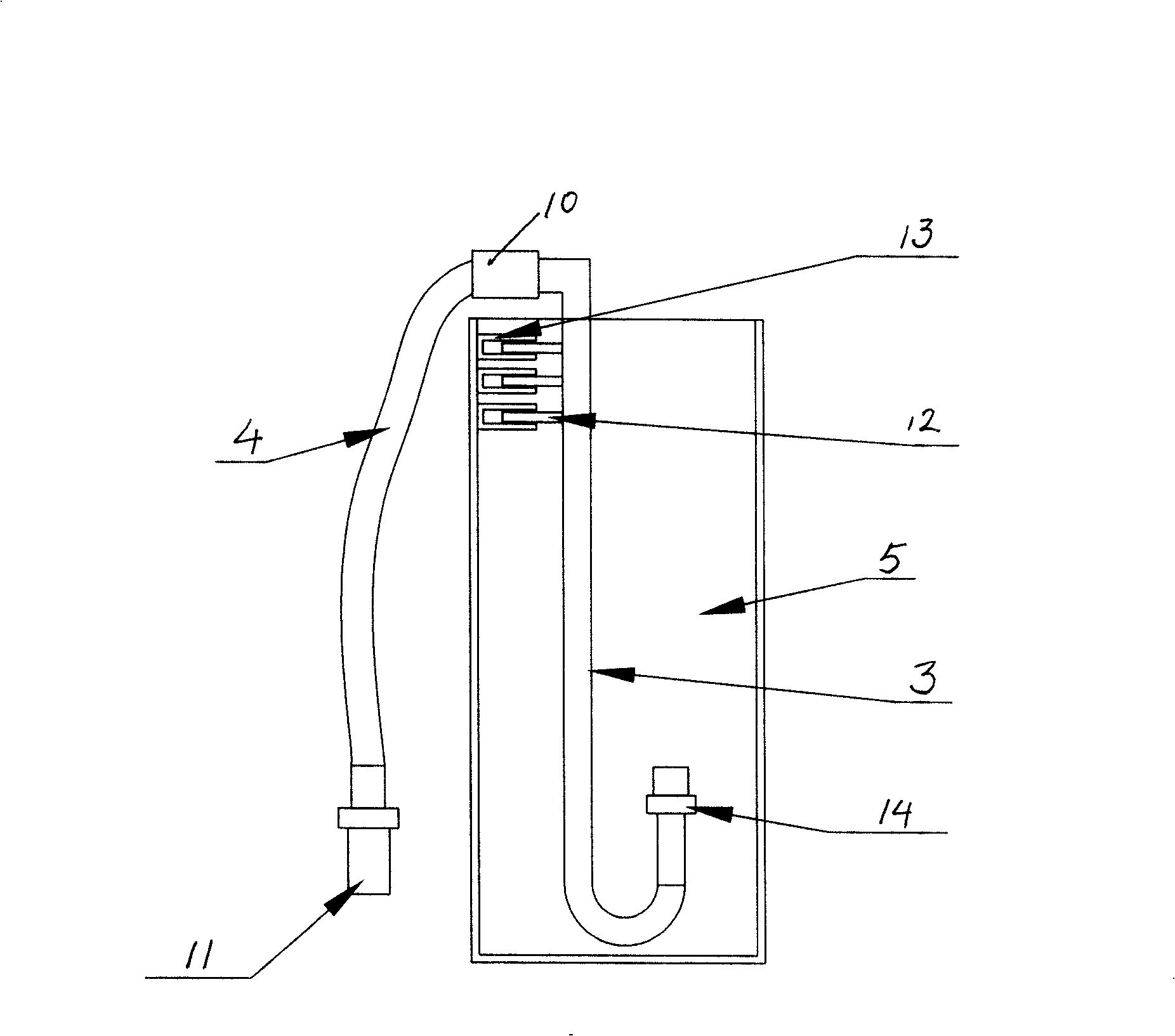

[0044] Example 1: 4000D

[0045] The metering pump 2 is a double metering pump 2 of 3.5ml / min, the rubber supply hose 1 adopts the double rubber supply hose 1, the filter on the curved pipe 3 adopts a butterfly filter 11, and the immersion length is 650mm, and the curved pipe 3 is placed on the acid bath 5 The positioning level is level 1. The filament fineness is 4440dtex / 1F, the unfolded width of the film tape is 40±6mm, and the thickness is 0.01-0.04mm. The dry breaking strength is 0.75-2.0CN / dtex, the dry breaking elongation is 12-20%, and the residual sulfur is ≤10mg / 100g silk.

Embodiment 2

[0046] Example 2: 2000D

[0047] The metering pump 2 is a metering pump 2 of 3.5ml / min. The filter on the curved pipe 3 adopts a butterfly filter 11 with an immersion length of 600 mm. The positioning level of the curved pipe 3 on the acid bath 5 is 2. The filament fineness is 2222dtex / 1F, the unfolded width of the film tape is 20±3mm, and the thickness is 0.01-0.04mm. The dry breaking strength is 0.8-0.2CN / dtex, the dry breaking elongation is 12-20%, and the residual sulfur is ≤10mg / 100g silk.

Embodiment 3

[0048] Example 3: 1100D

[0049] The metering pump 2 is a metering pump 2 of 2.0ml / min. The filter on the curved pipe 3 adopts a butterfly filter 11 with an immersion length of 550 mm. The positioning level of the curved pipe 3 on the acid bath 5 is 3. The filament fineness is 1222dtex / 1F, the unfolded width of the film tape is 11±2mm, and the thickness is 0.01-0.04mm. The dry breaking strength is 0.9-0.2CN / dtex, the dry breaking elongation is 12-20%, and the residual sulfur is ≤10mg / 100g silk.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com