Conditioning equipment for selectively harvesting corn stalk

A technology of corn stalks and straws, which is applied in the field of corn stalk harvesting and processing combined operating machines, and can solve the problems of harvesting ears and ignoring reasonable harvesting of straws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

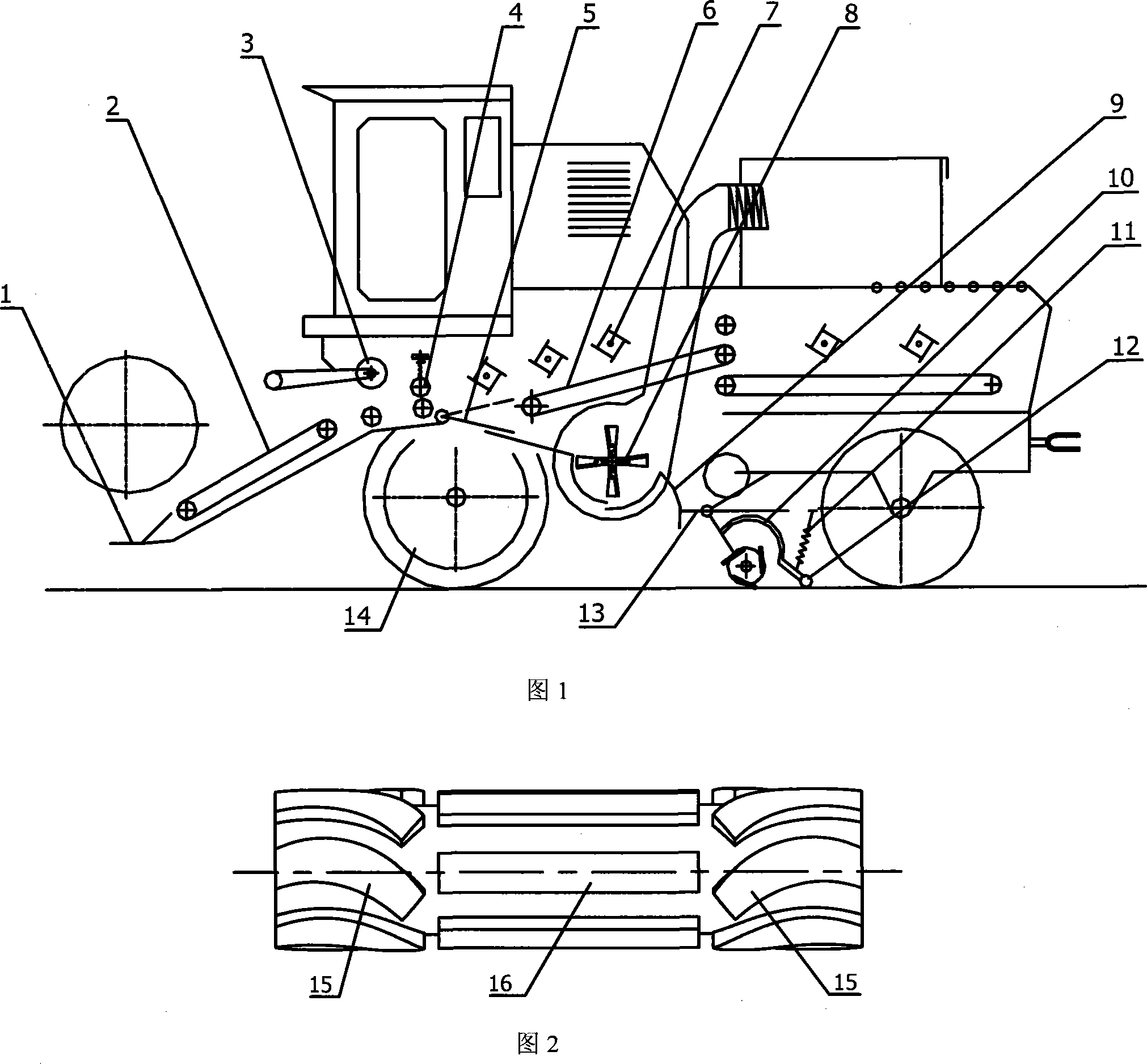

[0008] With reference to Fig. 1, Fig. 2 is an embodiment of the present invention, cutter (1) is connected with inclined conveyer (2), and the upper shaft of inclined conveyer (2) is hinged with frame (13), and header can be transported around inclined The upper shaft of the device (2) swings to realize harvesting different parts of the straw. The upper roller of the feeding pair (3) and the upper roller of the flattening roller (4) float up and down by the guide groove and the spring limit adjustment force. The rollers rotate in opposite directions to crush the straw, the front end of the valve (5) is hinged on the frame (13) and can be swiveled and shifted to realize logistics guidance, the conveyor (6) rotates, the pressing wheel (7) rotates and presses the straw, and the splitting The straw is sent out of the machine in strips and laid in strips to cool in the sun, and is used to prepare briquetted dry feed or briquetted fuel; the chopping device (8) rotates at a high speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com