Filter paper die cutting device of transfusion device automatic assembling machine

A technology of automatic assembly machine and infusion set, which is applied in the direction of filter fittings, instruments introduced into the body, metal processing, etc. It can solve the problems of not being able to be completely stamped, insufficient stamping speed of the cylinder, curling, etc., so as to prevent the incomplete stamping and falling , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

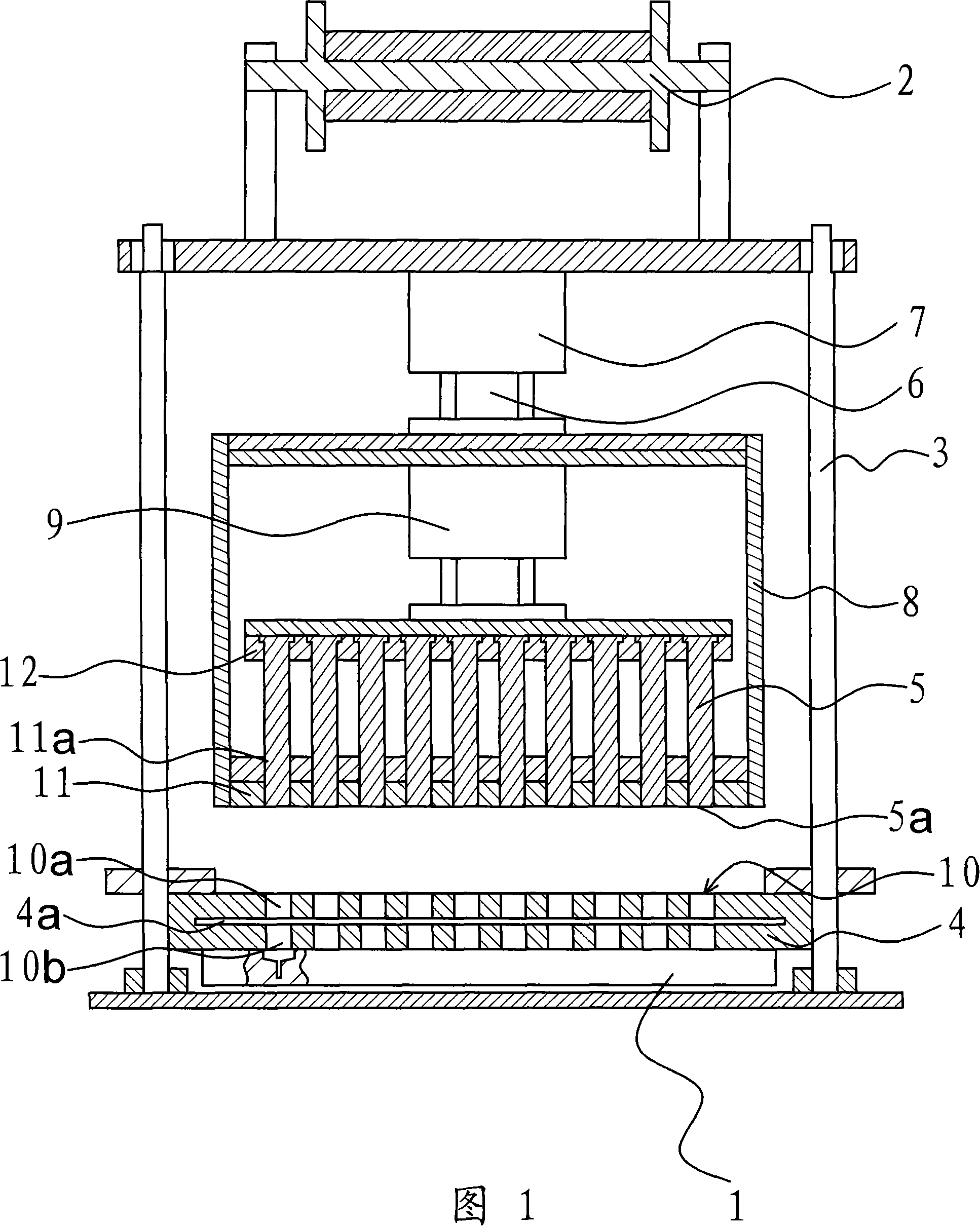

[0020] As shown in Figure 1, the filter paper punching device of the automatic infusion set assembly machine is fixed by a support 3, and a paper roll conveying mechanism 2 is fixedly connected to the support 3. A paper punching die 4 is fixed on the bottom of the support 3, and several die holes 10 are arranged on the paper punching die 4, and each die hole 10 is arranged in a row. The paper punching die 4 is provided with a transversely extending paper feed slot 4a for the filter paper belt to pass through, and the paper feed slot 4a separates each die hole 10 into an upper die hole 10a and a lower die hole 10b. The lower die hole 10b has a supporting effect on the filter paper. When the punching rod 5 is inserted into the die hole 10, it can be easily punched down, while the upper die hole 10a has a guiding effect. Above the punching die 4, there is a punching rod 5 arranged vertically in one-to-one correspondence with the die holes 10, and the punching rod 5 is fixed on a ...

Embodiment 2

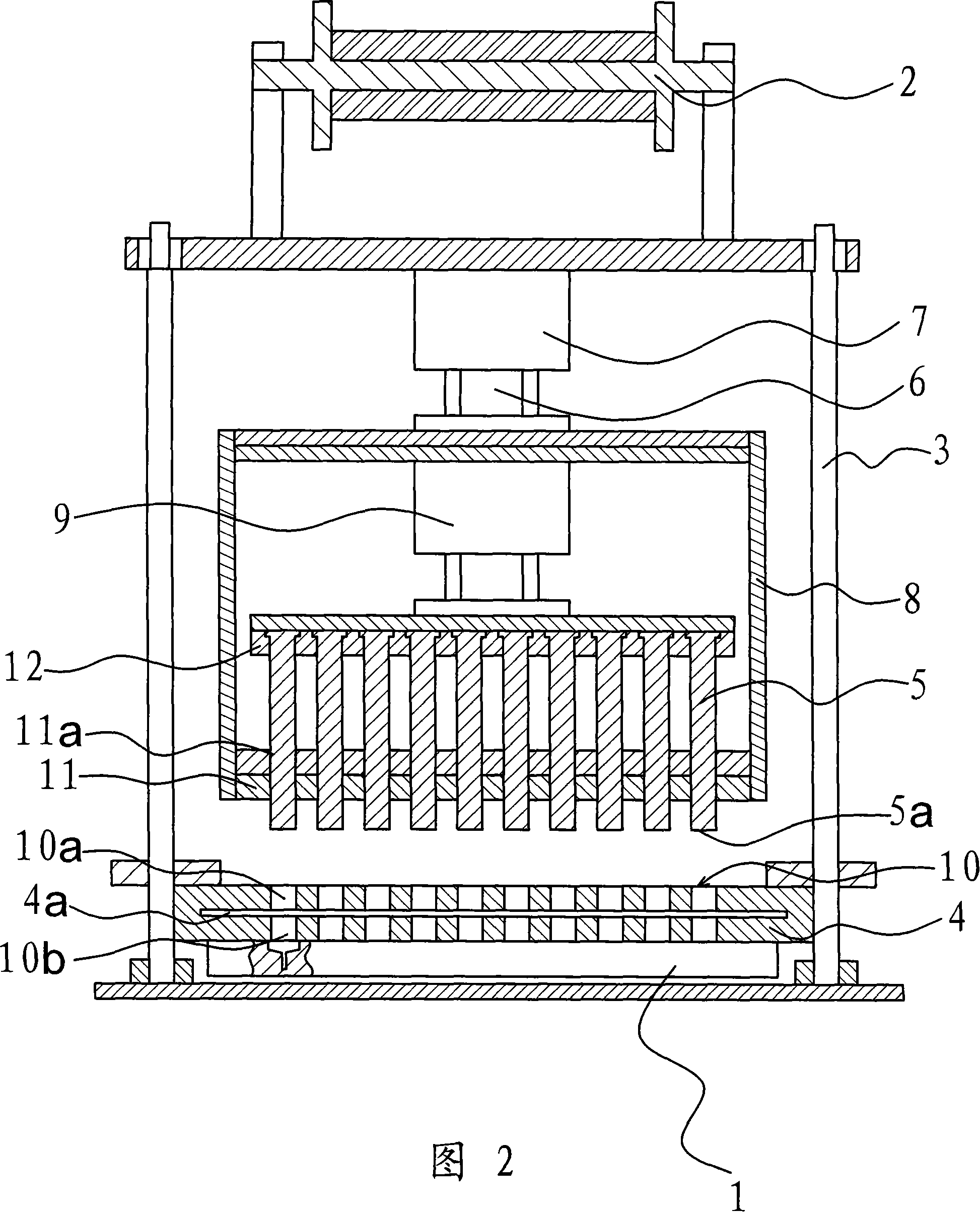

[0024] As shown in FIG. 2 , the structure and principle of this embodiment are basically the same as those of the first embodiment, except that the length of the punching rod 5 is greater than the distance between the second cylinder 9 and the punching rod guide seat 11 . The punching rod 5 passes through the punching rod guide seat 11 and grows a part, so that the filter paper punched down can be directly sent into products with deep notches such as bottle inserting needles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com