Batch supplying fermentation technique for producing acetonic acid oxidase high-effectively by using recombinant bacillus coli

A technology of recombinant Escherichia coli and pyruvate oxidase, applied in the field of bioengineering, can solve the problems of low fermentation level and high market price of pyruvate oxidase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

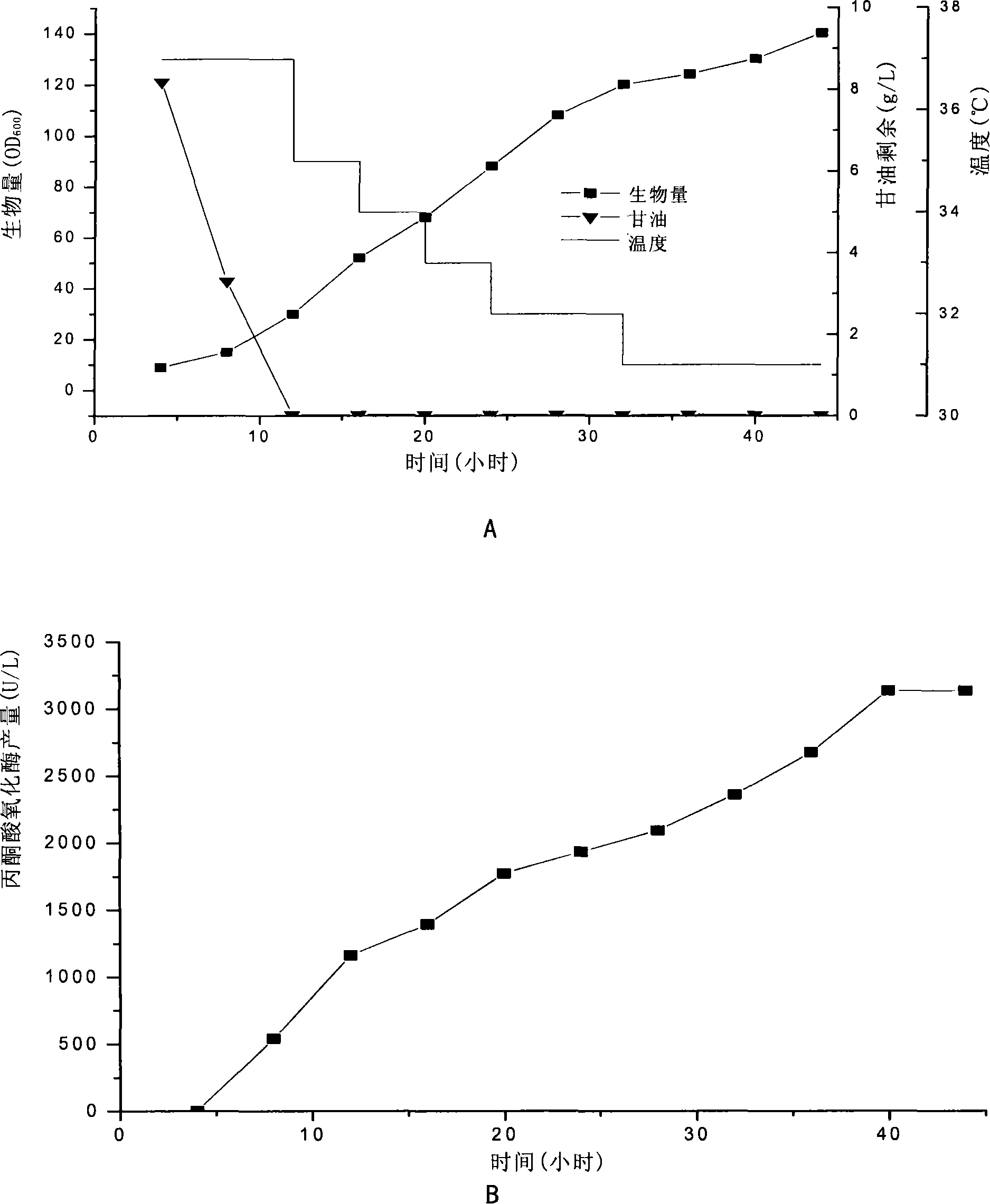

[0079] Example 1 Fermentation to the fermentation process of gradient cooling at the end of the initial growth stage

[0080] The E.coli DH5d / pSMLPyOD seeds stored in glycerol tubes were activated in LB medium for 12 hours, and then transferred to a fermenter at a 10% inoculum size. The parameters of the fermenter are set as follows: the temperature is 37° C., the initial ventilation rate is 5 L / min, the initial stirring speed is 300 rpm, and the initial dissolved oxygen (DO) is 100%. The dissolved oxygen level in the fermentation process is controlled between 30-40% by adjusting the stirring speed and the ventilation rate, and the ammonia water controls the pH to 7.

[0081]After about 11-12 hours of fermentation, the dissolved oxygen starts to rise. When it rises to 70-80%, it indicates that the initial growth stage is over. At this time, the temperature is adjusted to 35°C and feeding is started. The feeding rate is 0.2ml / min / L. After 4 hours, the temperature was adjusted ...

Embodiment 2

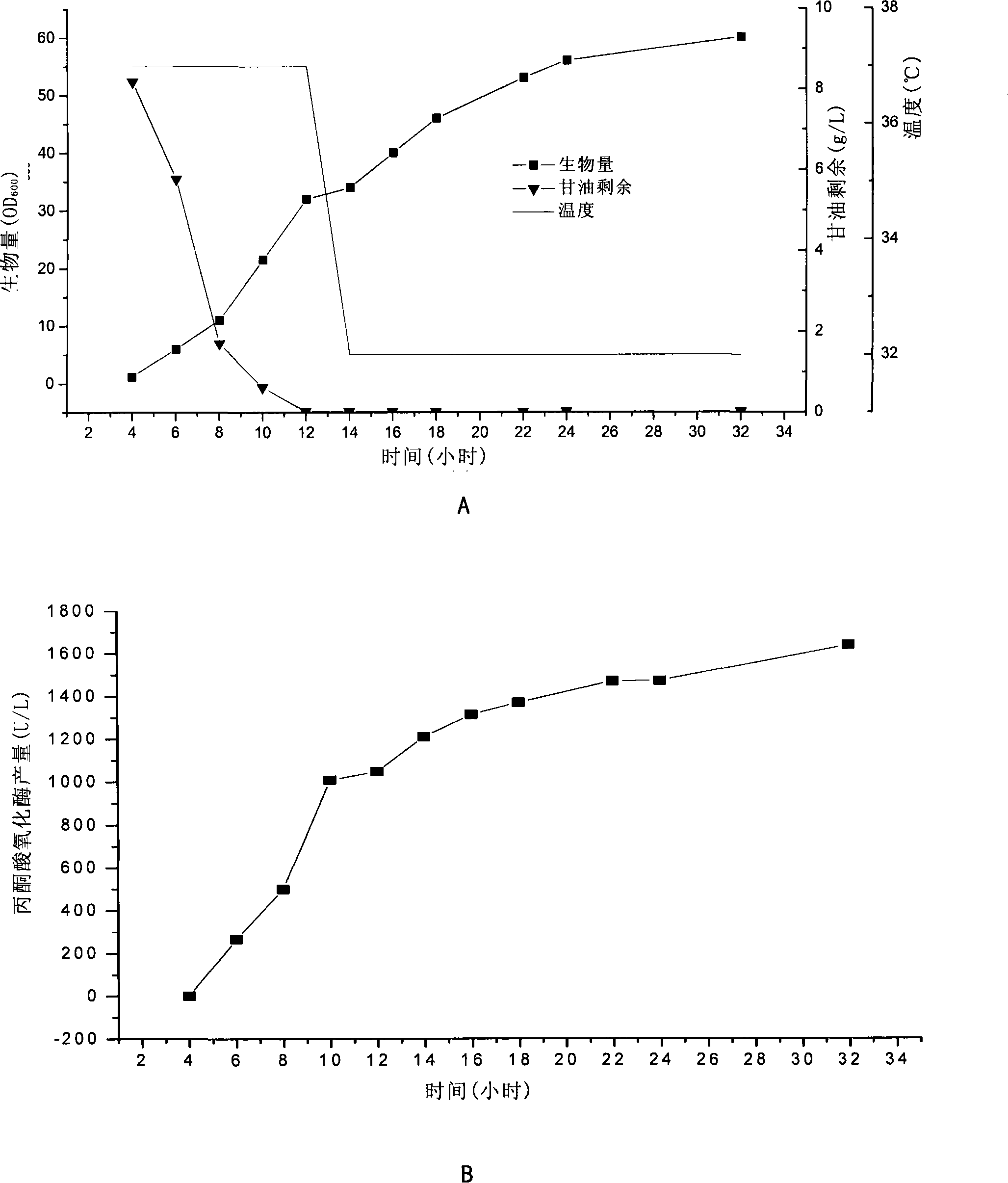

[0083] Fermentation process of one-time cooling when embodiment 2 fermented to the end of the initial growth stage

[0084] The culture medium and the initial fermentation stage are the same as in Example 1.

[0085] After 11-12 hours of fermentation, the dissolved oxygen starts to rise, and when it rises to 70-80%, it indicates that the initial growth stage is over, and the fermentation temperature is adjusted to 32° C. at this time. Reduce the stirring speed to 450RPM, and add a small amount of feeding medium (5-10ml). After 2-3 hours, the cells start to grow and metabolize, and the dissolved oxygen decreases. When the dissolved oxygen rises again, start feeding, and the feeding rate is 0.1mL / min / L, when the dissolved oxygen drops below 30%, control it to 30-40% by increasing the speed and ventilation. Ammonia water controls the pH to 6.7±0.1. If the pH rises to 7 spontaneously, it indicates that the feeding rate is too low. At this time, the feeding rate should be increas...

Embodiment 3

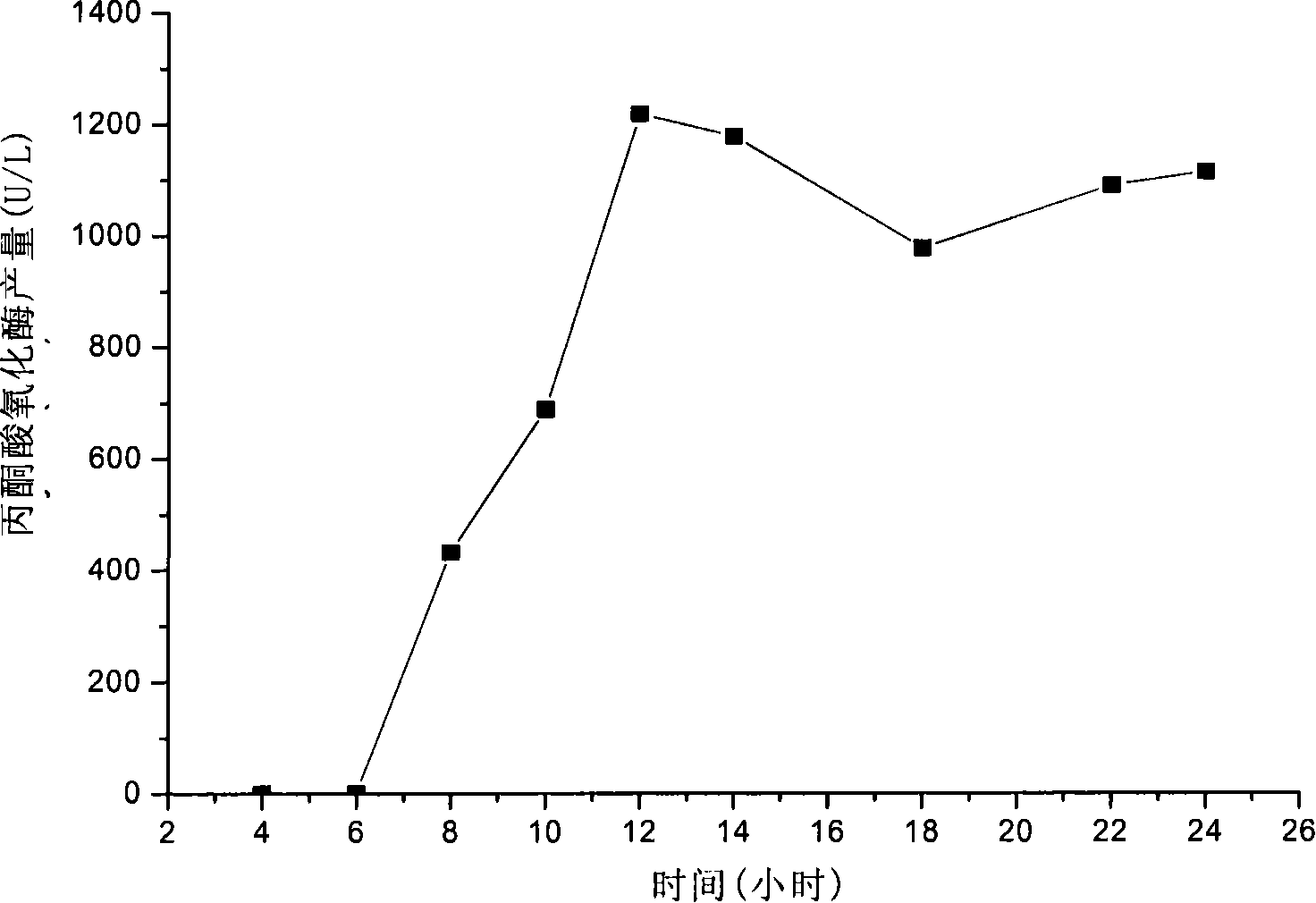

[0087] All adopt the fermentation process of 37 ℃ in the fermentation process of embodiment 3

[0088] The culture medium is the same as in Example 1. Ferment for 11-12 hours, the initial growth stage is over, and the dissolved oxygen starts to rise. Keep the fermentation temperature at 37°C. When the dissolved oxygen rises above 60%, start feeding. The feeding rate is 1ml / min, and the feeding rate is constant. , until the end of fermentation. The dissolved oxygen level in the fermentation process is controlled between 30-40% by adjusting the stirring speed and the ventilation rate, and the pH of the ammonia water is controlled to be 6.7±0.2.

[0089] Adopt this fermentation technique, after 24 hours, bacterial concentration is no longer increasing, and fermentation finishes, and bacterial cell concentration (OD 600 ) reached 60, and the output of pyruvate oxidase reached the highest 1200U / L in 12 hours, and then decreased again. For the fermentation process curve, see im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com