Control system for micro-nano sample in electronic microscope

An electron microscope and control system technology, applied in circuits, discharge tubes, electrical components, etc., can solve the problems of limited space, increased repeated testing and personalized modification, and decreased automatic operation ability, so as to achieve easy operation and avoid affecting the vacuum degree. and test accuracy, the effect that is conducive to observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

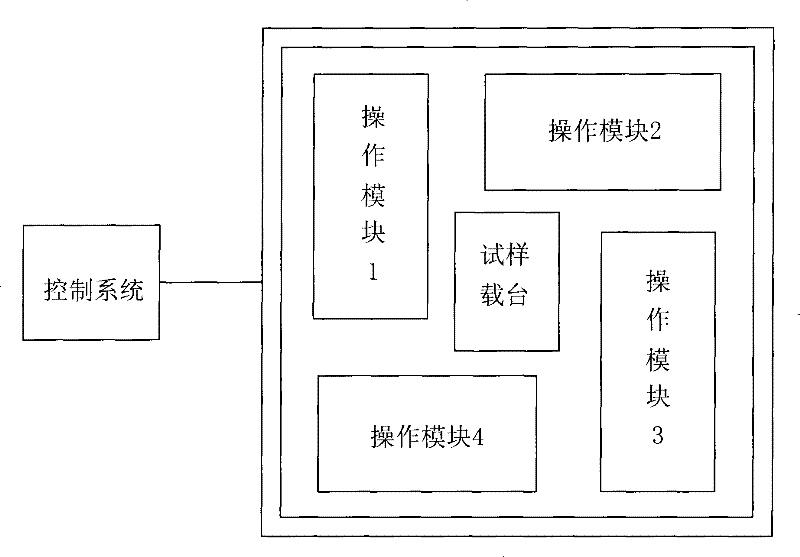

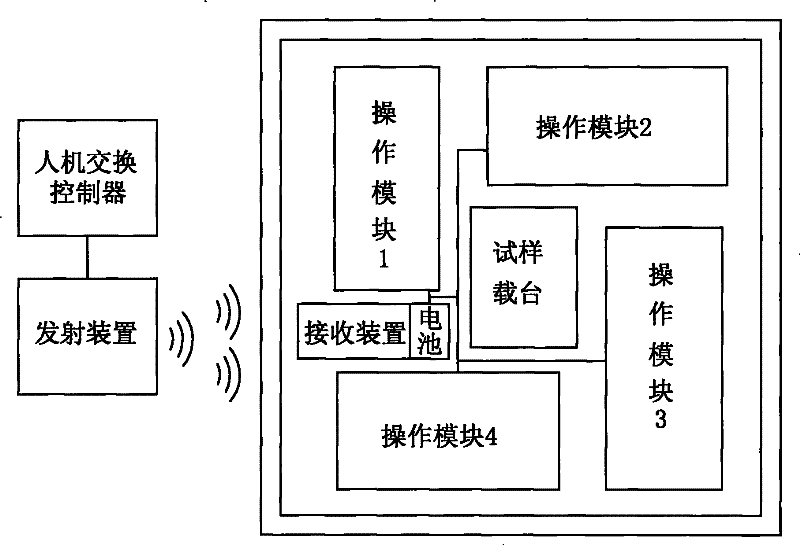

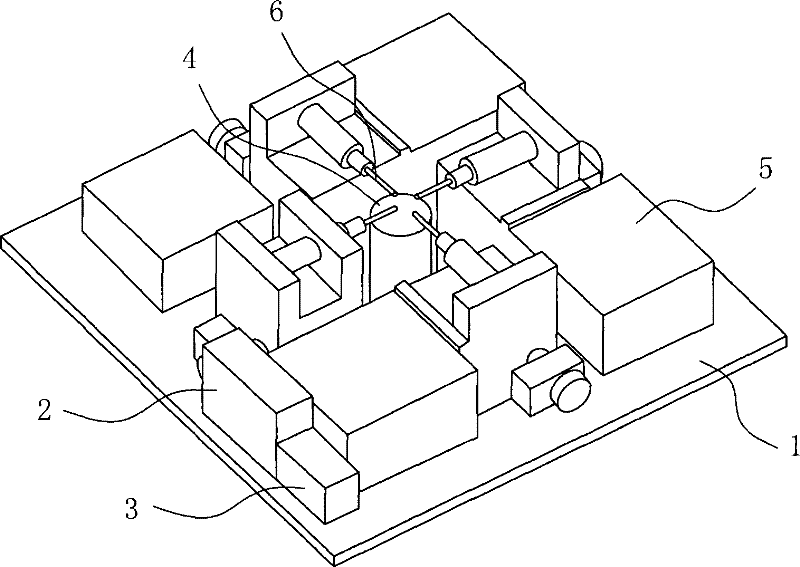

[0024] Embodiment one: see Figure 1 to Figure 3 As shown, a control system for micro-nano samples under an electron microscope includes an operating platform 1, 4 operating modules 5 arranged on the platform, a sample carrier 4 for carrying samples, and each operating module 5 A control device connected to a control circuit, the control device includes a signal transmitting device, a signal receiving device 2 and a battery assembly 3 compatible with a vacuum environment, the signal receiving device 2 is arranged on the operating platform 1, and its signal The output end is connected to each of the control circuits, the signal transmitting device is connected to a man-machine exchange control, and sends a radio frequency (RF) signal to the signal receiving device 2 through radio waves, the battery assembly 3 is a solid battery, Its output terminal is connected with each control circuit and the power supply terminal of the signal receiving device 2 to supply power to the receiv...

Embodiment 2

[0026] Embodiment two: see Figure 4As shown, a control system for micro-nano samples under an electron microscope includes an operating platform, an operating module set on the platform, a sample carrier carrying samples, and a control device connected to the control circuit in the operating module , the control device includes a signal transmitting device, a signal receiving device and a battery assembly compatible with a vacuum environment, the signal receiving device is arranged on the operating platform, and the battery assembly is composed of a liquid battery and a sealed battery wrapped outside the battery The liquid battery and the sealed case are filled with air, and the electrode terminals of the battery are led out of the sealed case through wires, connected to the receiving device and the power supply end of the control circuit, and supply power to both. The signal output terminal of the device is connected with the control circuit, the signal transmitting device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com