Coffee maker

A coffee machine and coffee technology, applied in beverage preparation devices, household appliances, applications, etc., can solve the problems that the coffee outlet seat cannot be adjusted horizontally, and the container cannot be filled with coffee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

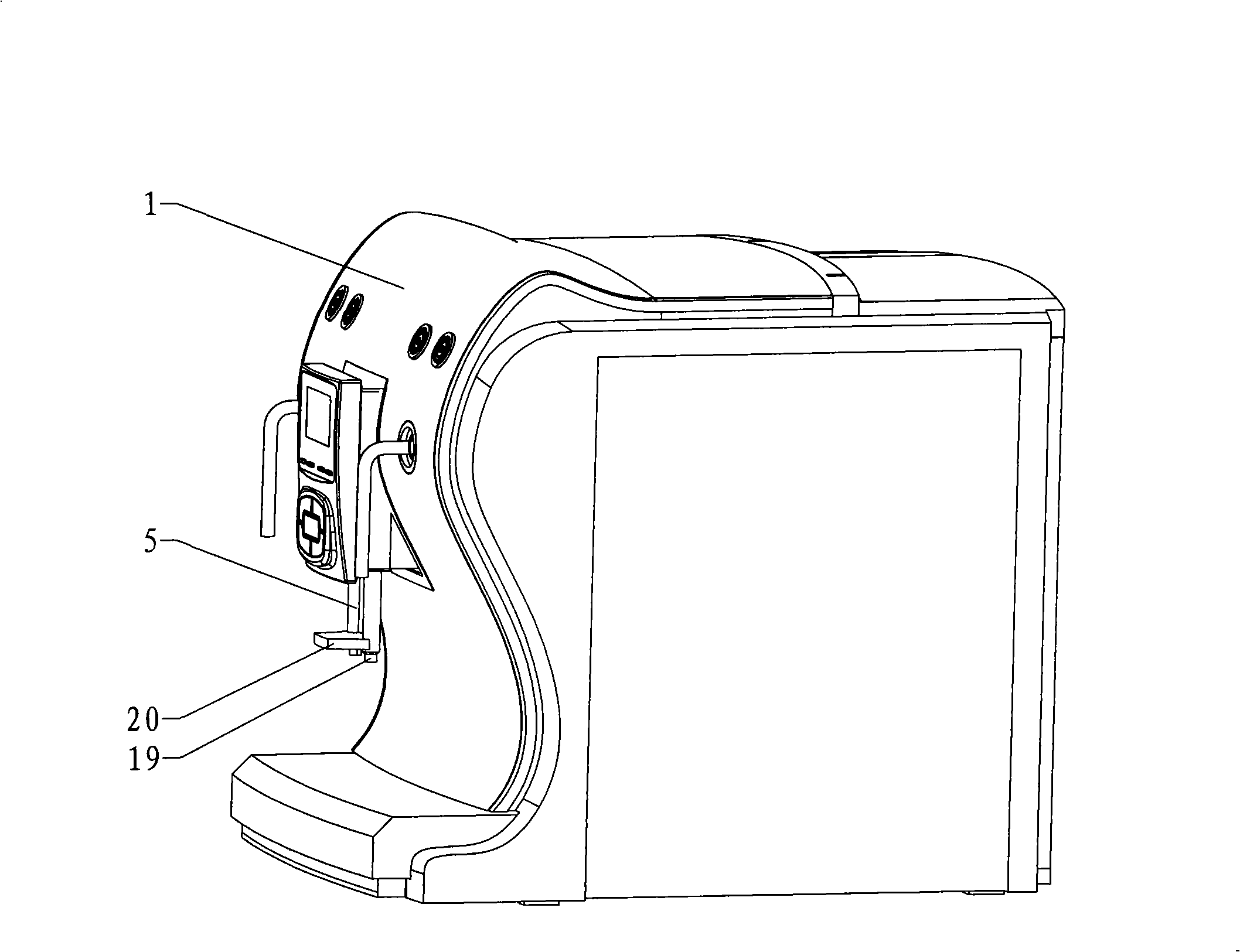

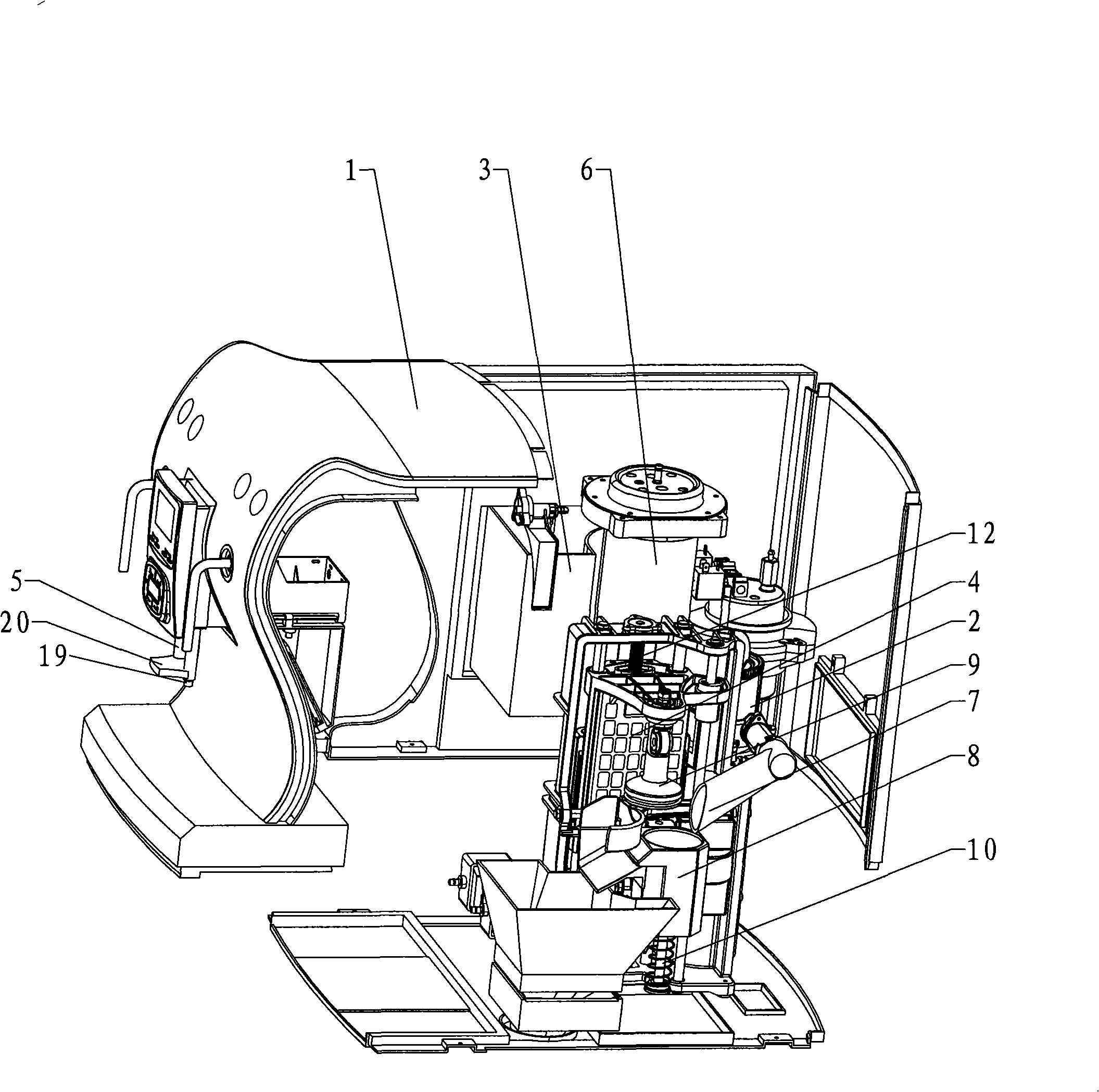

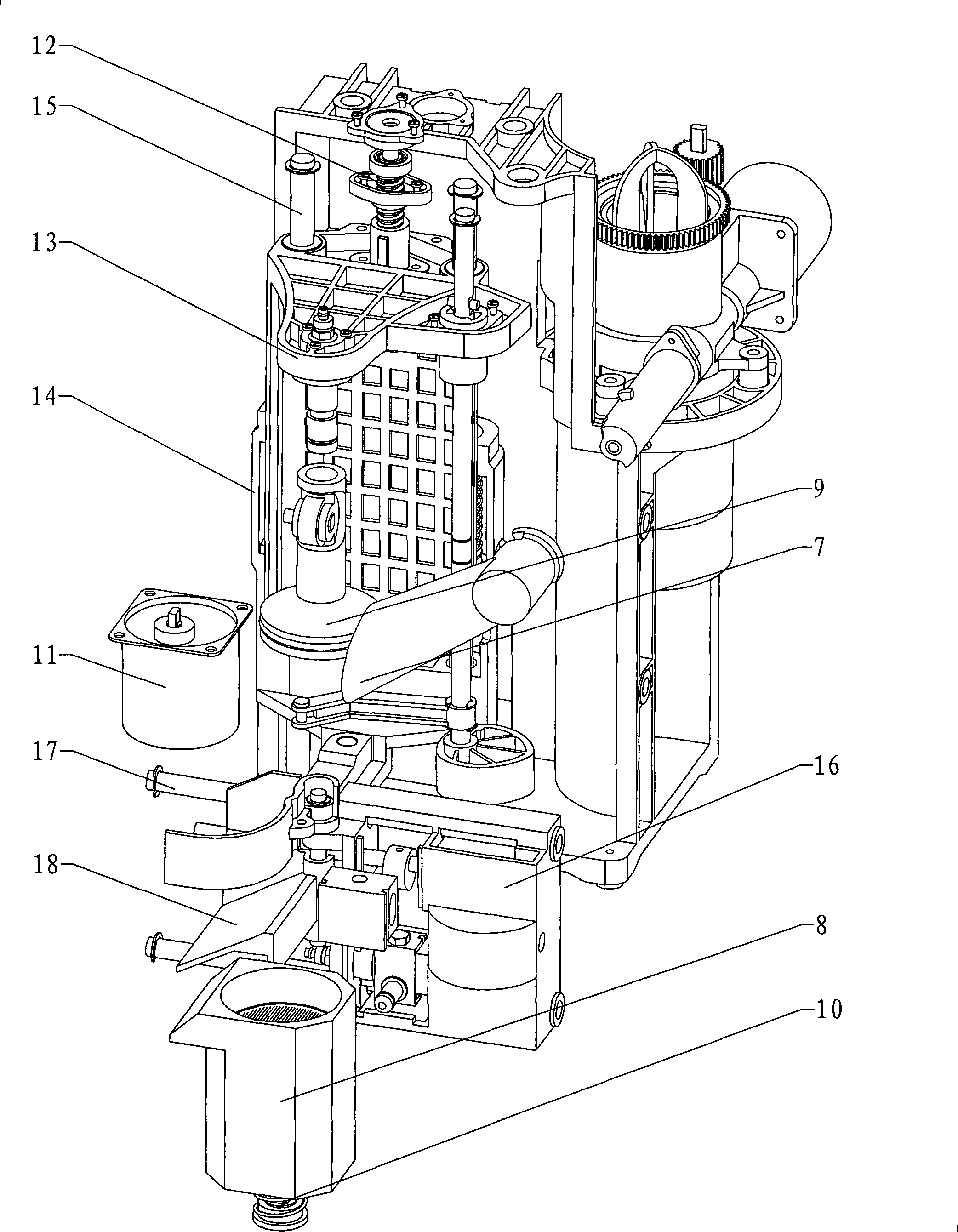

[0015] combine figure 1 , figure 2 , image 3 , Figure 4 As shown: the casing 1 of the coffee machine in this embodiment is provided with a grinder mechanism 2 , a water supply mechanism 3 , a brewing mechanism 4 and a liquid outlet mechanism 5 . The water outlet pipe in the water supply mechanism is connected to the heating container 6 , a heater is arranged in the heating container 6 , and the water outlet pipe of the heating container communicates with the brewing mechanism 4 . The brewing mechanism includes: a cylinder 8 into which coffee powder can be placed, and upper and lower pistons 9 and 10 can move in the cylinder. The brewing mechanism is provided with a motor 11, the motor drives the screw 12 to rotate, the screw drives the upper supporting plate 13 and the lower supporting plate 14 to move along the longitudinal guide rail 15, the upper supporting plate 13 is connected with the upper piston 9, and the lower piston 10 is installed in the cylinder body 8; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com