Digital intelligent electric ballast of high power ultraviolet lamp tube

A technology of electronic ballasts and ultraviolet lamps, applied in electric light sources, electrical components, lighting devices, etc., to achieve the effects of suppressing input AC surge current, suppressing radio frequency interference, and limiting harmonic distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the structural details of the utility model embodiment are described in further detail:

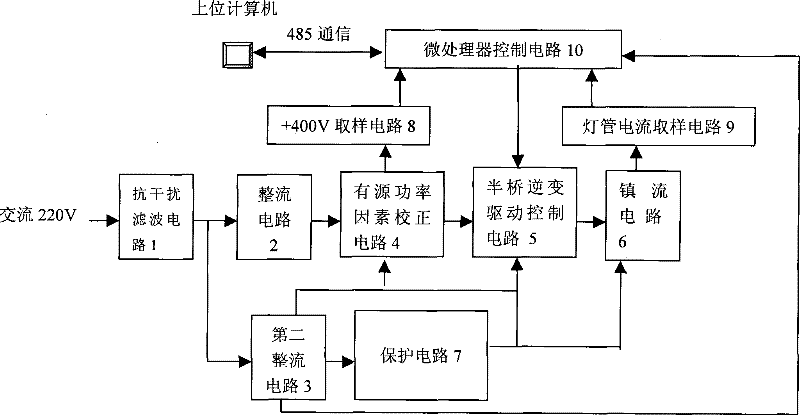

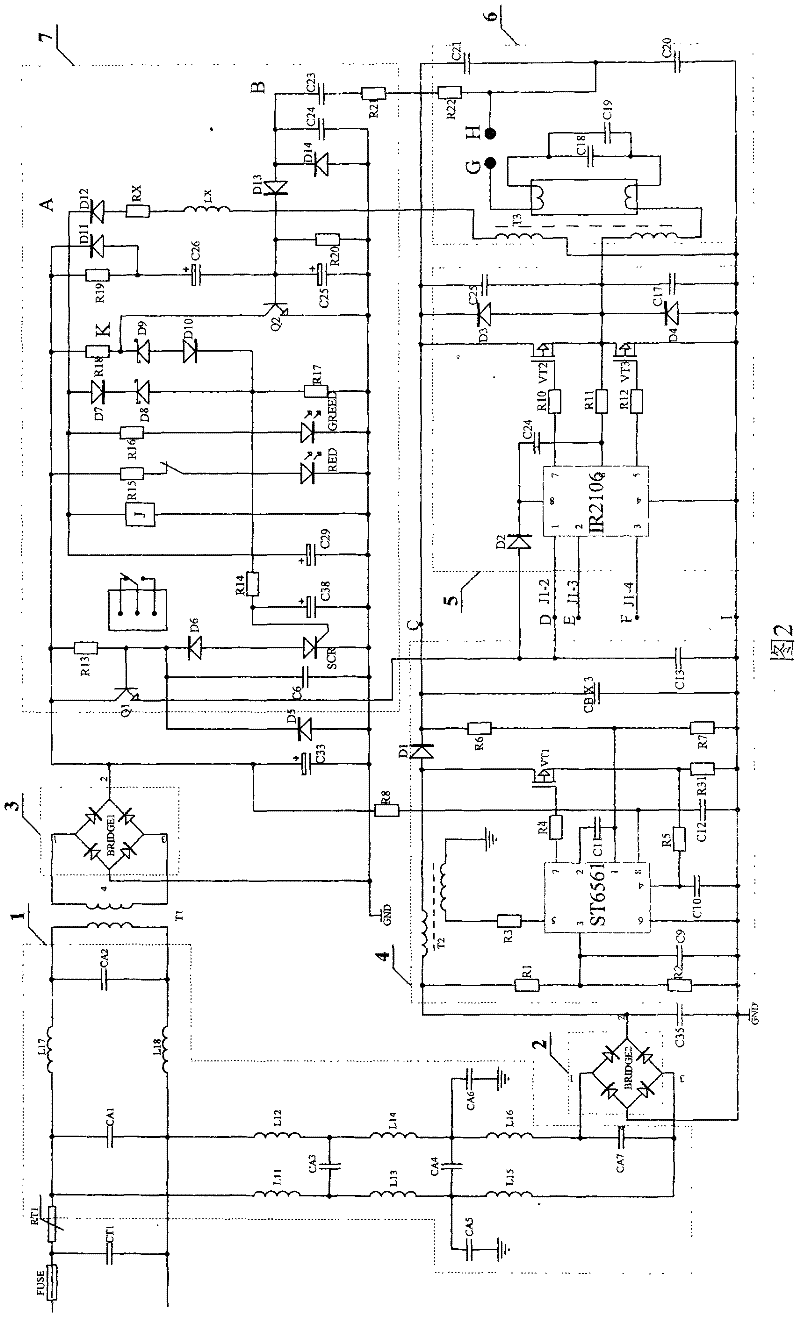

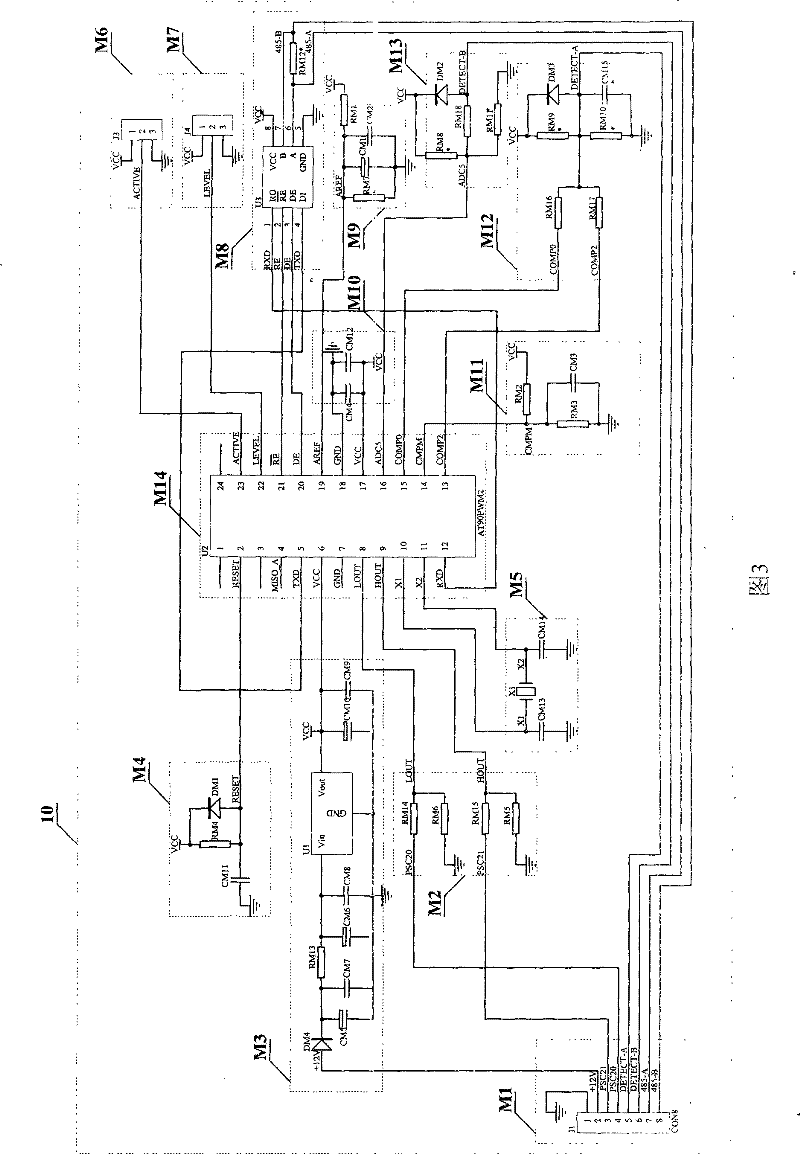

[0021] like figure 1 As shown, the intelligent electronic ballast equipped with 320W ultraviolet lamp is composed of anti-interference filter circuit 1, rectifier circuit 2, second rectifier circuit 3, active power factor correction circuit 4, half-bridge inverter drive control circuit 5, A ballast circuit 6, a protection circuit 7, a lamp current sampling circuit 8, a +400V sampling circuit 9 and a microprocessor control circuit 10 are formed. The specific circuit composition of each sub-circuit is described below (such as figure 2 , 3 , 4, 5 shown):

[0022] 1. Anti-interference filter circuit 1

[0023] The AC 22V input power is input to the anti-interference filter circuit 1 through the overcurrent and overvoltage protection circuit composed of the fuse FUSE, the varistor RT1 and the varistor CT1. The anti-interference filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com