Vibration absorbing device

A technology of adsorption device and suction cup, which is used in motor vehicles, transportation and packaging, etc., can solve the problems of high power consumption, large volume, and limit the development of wall-climbing robots, and achieve the effect of reliable energy consumption, low energy consumption, and stable adsorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings.

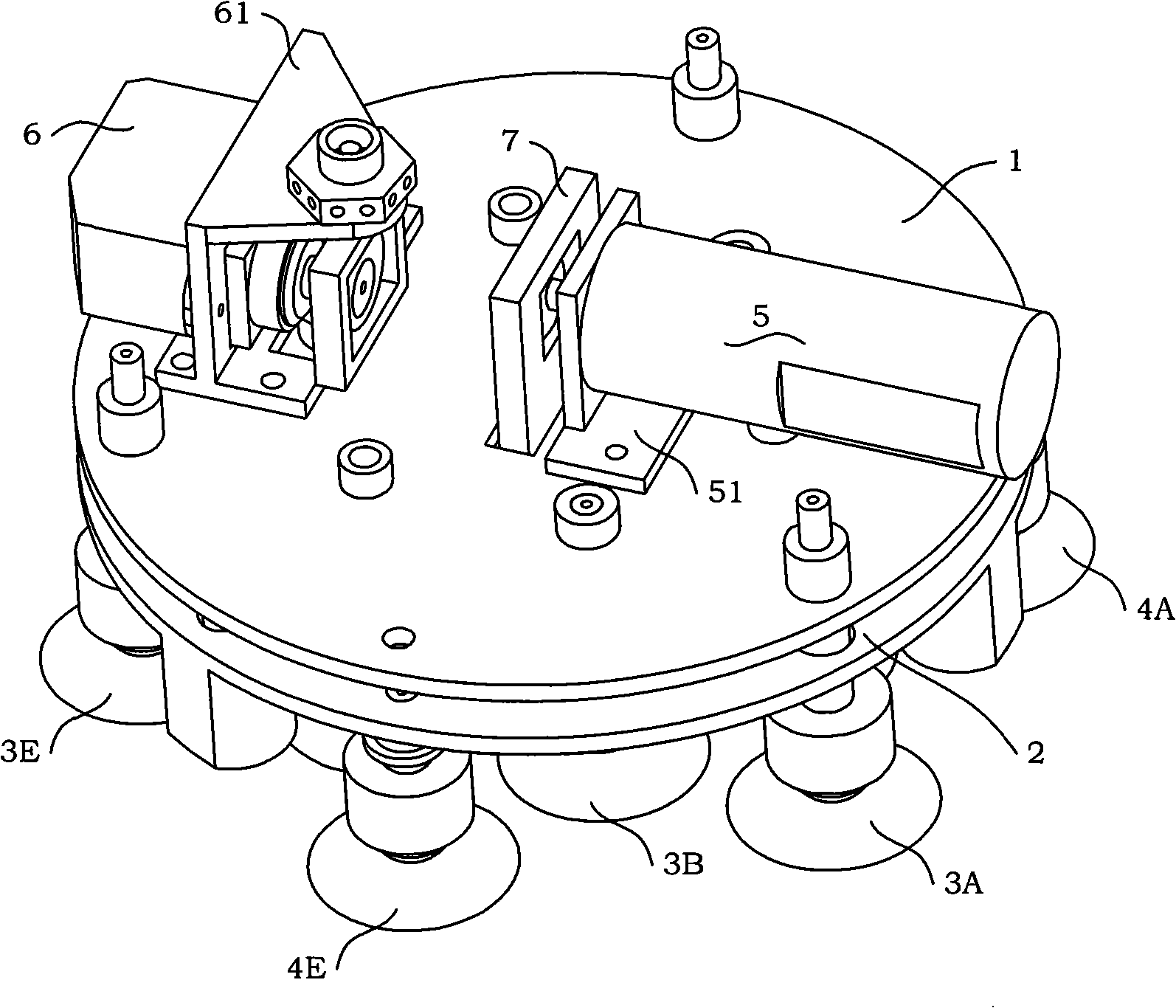

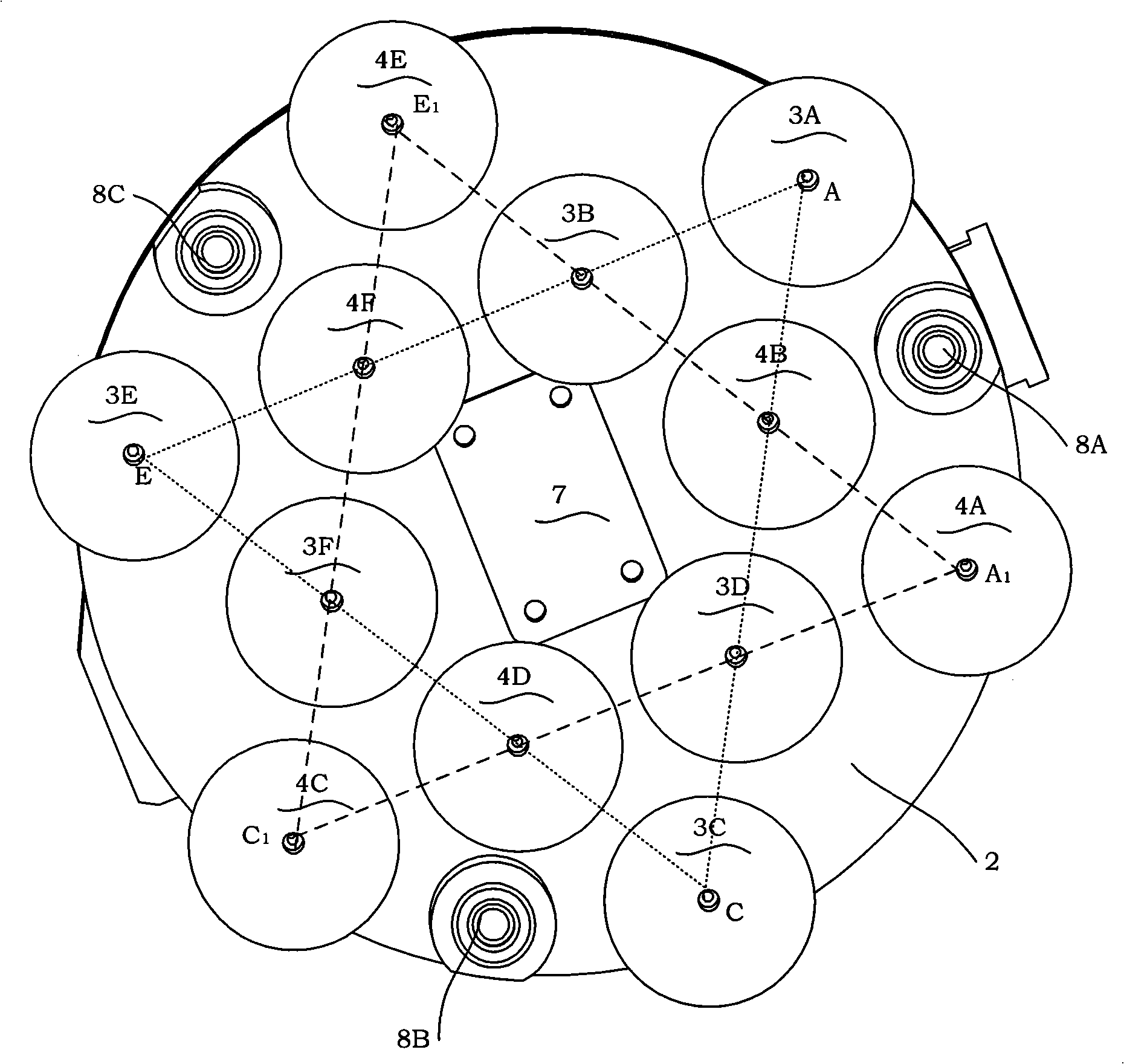

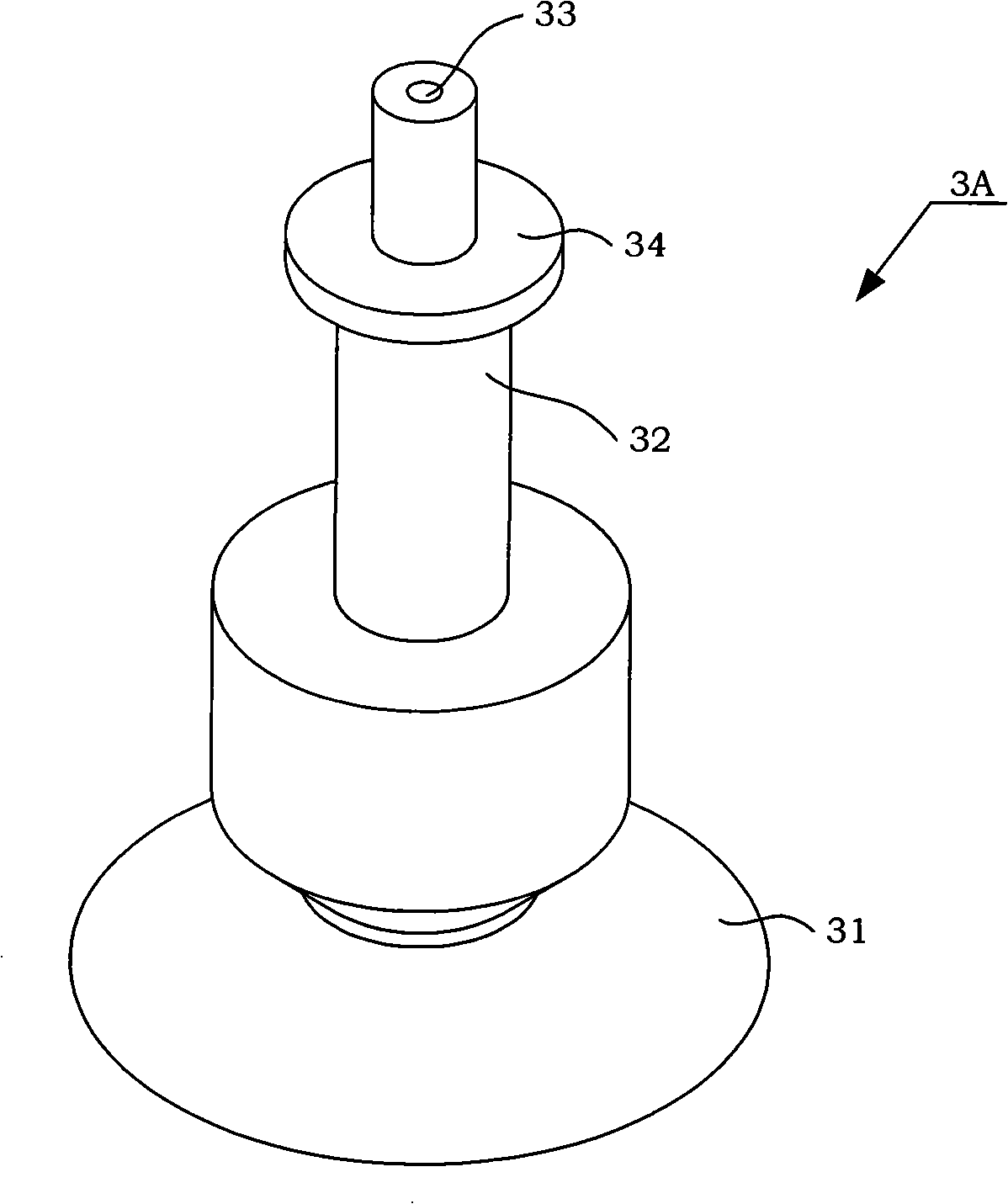

[0040] The vibration adsorption device of the present invention, through two relatively parallel suction cup mounting plates (upper suction cup mounting plate 1, lower suction cup mounting plate 2), and twelve vacuum suction cups, adopt suction cups to be divided into two groups and respectively installed on the upper suction cup mounting plate 1 , The mode below the lower suction cup mounting plate 2 makes two groups of suction cups spaced from each other. Through the connection of three parallel ball slide rails (by ball bearings, linear guide rails, and guide rods) set on the upper suction cup mounting plate 1 and the lower suction cup mounting plate 2, the relative position of the upper suction cup mounting plate 1 and the lower suction cup mounting plate 2 is ensured. Motion has only one degree of freedom. The eccentric wheel slider mechanism composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com