Magnetic gear drive stepless shift transmission driving system

A technology of transmission drive and stepless speed change, which is applied in the direction of electromechanical transmission, electric components, electrical components, etc., and can solve problems such as mechanical noise and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

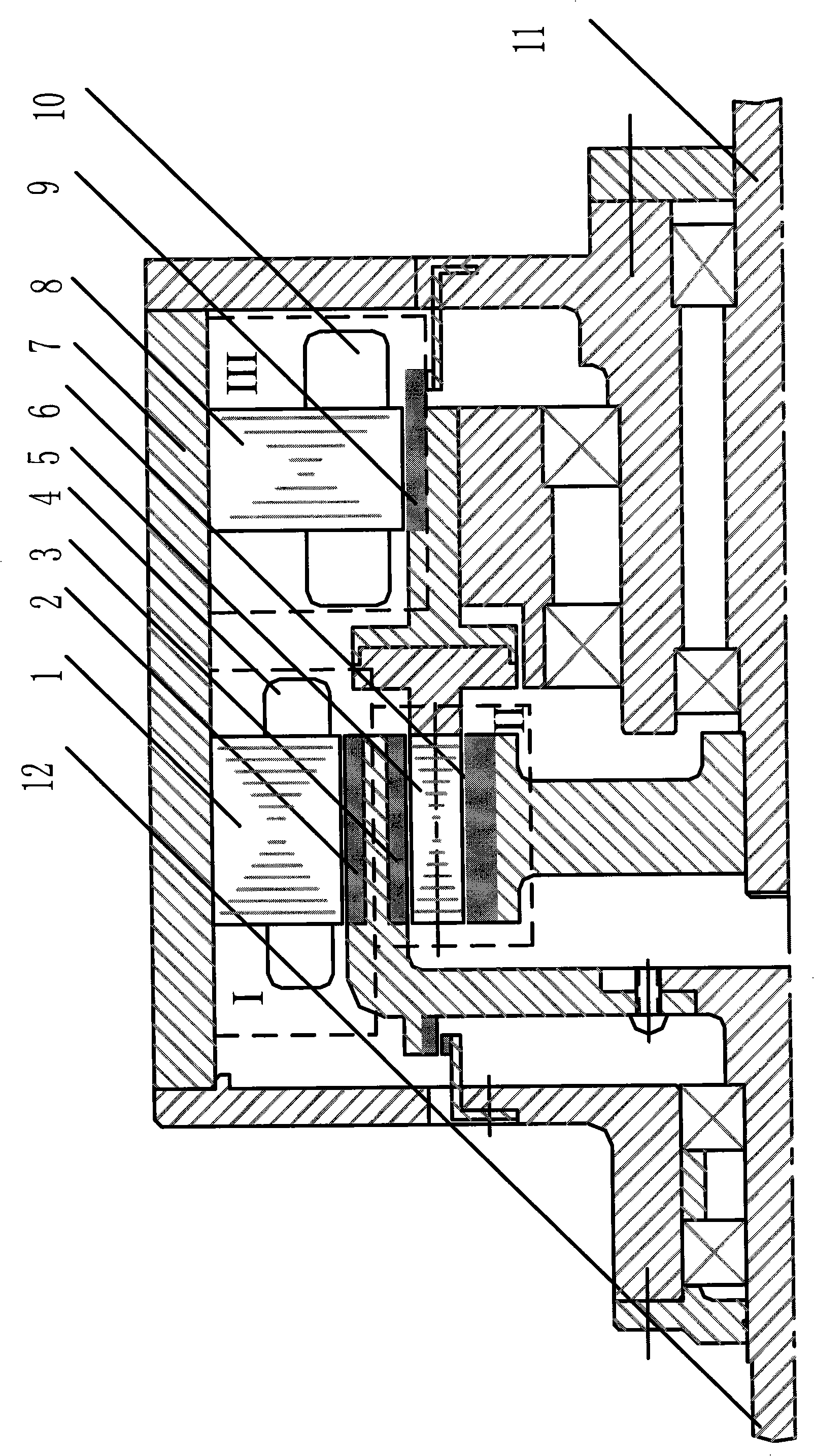

[0006] A preferred embodiment of the present invention is described as follows in conjunction with accompanying drawing:

[0007] Part I in the figure is a permanent magnet motor, its 1 is a stator core, 2 is a rotor permanent magnet, and 4 is a stator winding. Part II is the magnetic gear, 3 is the peripheral permanent magnet of the magnetic gear, 5 is the magnetic adjustment coil, and 6 is the permanent magnet of the inner ring of the magnetic gear. Part III is another permanent magnet motor, 8 is the stator core, 9 is the rotor permanent magnet, and 10 is the stator winding. 7 is support, is used for fixing the stator of two motors, and 11 is the input shaft of mechanical energy, and its one end links to each other with motor, and the other end links to each other with the inner ring of magnetic gear. 12 is output shaft, and its one end links to each other with load, and the other end links to each other with the outer ring of magnetic gear and the rotor of the first motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com