Complex grease additive

A grease additive and dispersant technology, which is applied in the direction of additives, lubricating compositions, thickeners, etc., can solve the problem of grease anti-wear performance, limit working ability effect is not obvious, grease improvement has not made substantial progress, graphite Add problems such as weak functionality to achieve the effect of improving the limit working capacity, simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

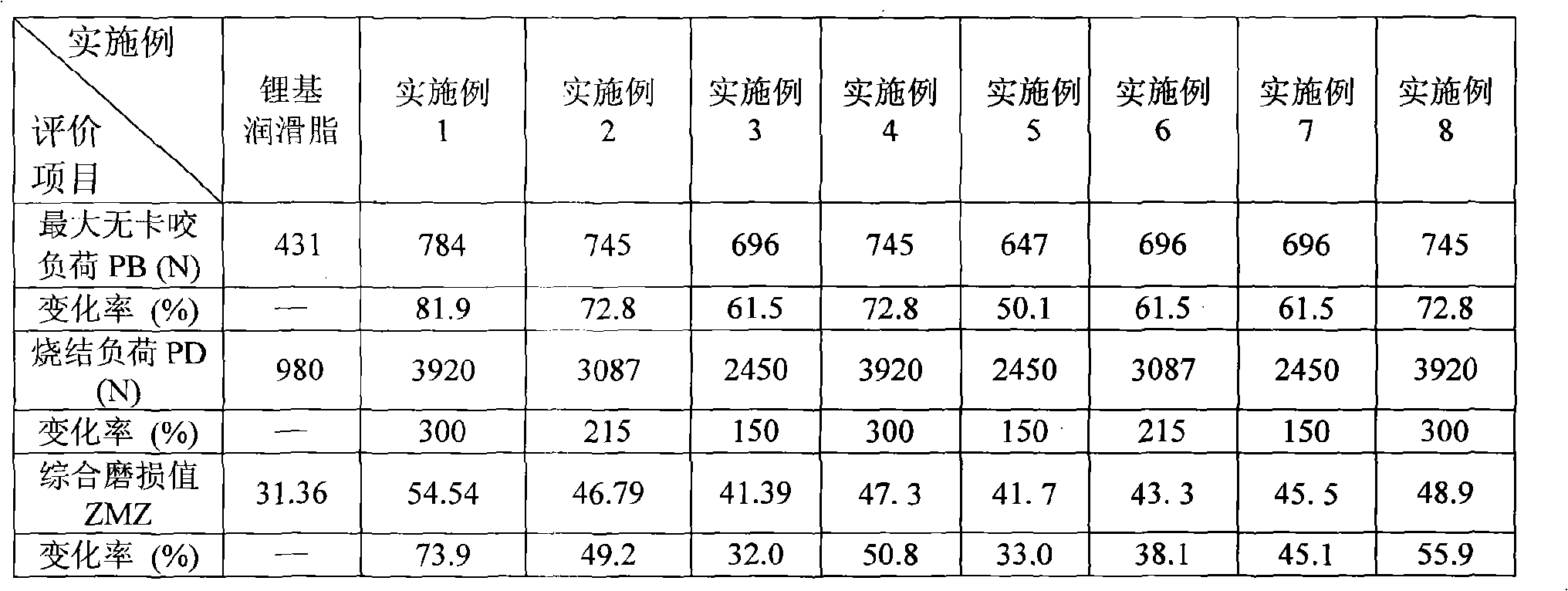

Examples

Embodiment 1

[0019] Add 5 parts of polyisobutylene succinimide, 20 parts of sulfurized isobutylene, 5 parts of thiourethane, 5 parts of benzotriazole fatty acid amine salt, and 35 parts of base oil 500SN into the blending kettle, heat to about 65°C to disperse Stir for about 2 hours, vacuum and negative pressure dehydration for about 2 hours; then, send the above product into the saponification kettle, add 10 parts of fatty acid lithium soap, 20 parts of graphite, disperse and stir for about 2.5 hours to saponify; then, pump the above product Grind in a grinder for about 2.5 hours; then, filter the above-mentioned product through a filter whose filter diameter is controlled to be no more than 15 μm to obtain a finished compound grease additive.

Embodiment 2

[0021] Each component in Example 1 is changed as follows: graphite is 49 parts, dispersant is 3 parts of bis-succinimide, extreme pressure antiwear agent is 13 parts of sulfurized isobutylene, zinc dialkyldithiocarbamate 4 parts and 3 parts of benzotriazole fatty acid amine salt, the thickener is 7 parts of fatty acid lithium soap, the base oil is 15 parts of base oil 150SN and 6 parts of base oil 350SN. Except this, according to the same method as Example 1, the finished compound grease additive was obtained.

Embodiment 3

[0023] The components in Example 1 were changed as follows: 35 parts of graphite, 7 parts of monosuccinimide as dispersant, 15 parts of triphenyl thiophosphate and benzotriazole fatty acid amine as extreme pressure antiwear agent 4 parts of salt, 7 parts of fatty acid lithium soap as thickener, 32 parts of base oil 350SN. Except this, according to the same method as Example 1, the finished compound grease additive was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com