Method for manufacturing hollow board sandwich layer material

A production method and hollow board technology are applied in the direction of manufacturing tools, wood processing appliances, and the joining of wooden veneers, which can solve the problems of labor-intensive, complex structure and high precision requirements, and achieve a wide range of applications and high production efficiency. , the effect of less material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

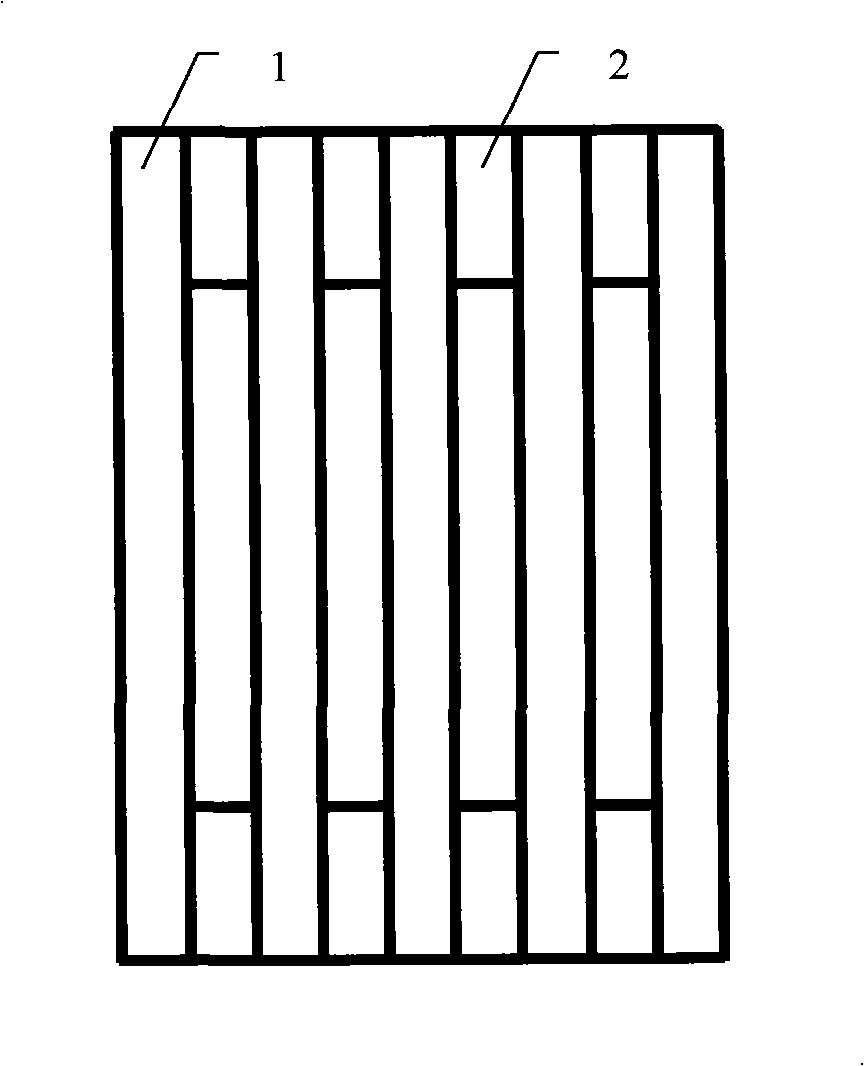

[0016] The moso bamboo is cut off, cut open, knotted, yellowed and greened, cut into strips, and processed into long and short bamboo strips with a width of 20mm and a thickness of 3mm. The length of the long bamboo strips depends on the specifications of the board. The length of the short bamboo strips is 15-30cm, and the bamboo strips of equal thickness are machine-woven with cotton and linen threads into such figure 2 The core material of the long-short strip unit member realizes the "integralization" of the core material and is used to make the core material of the hollow thick curtain bamboo plywood.

Embodiment 2

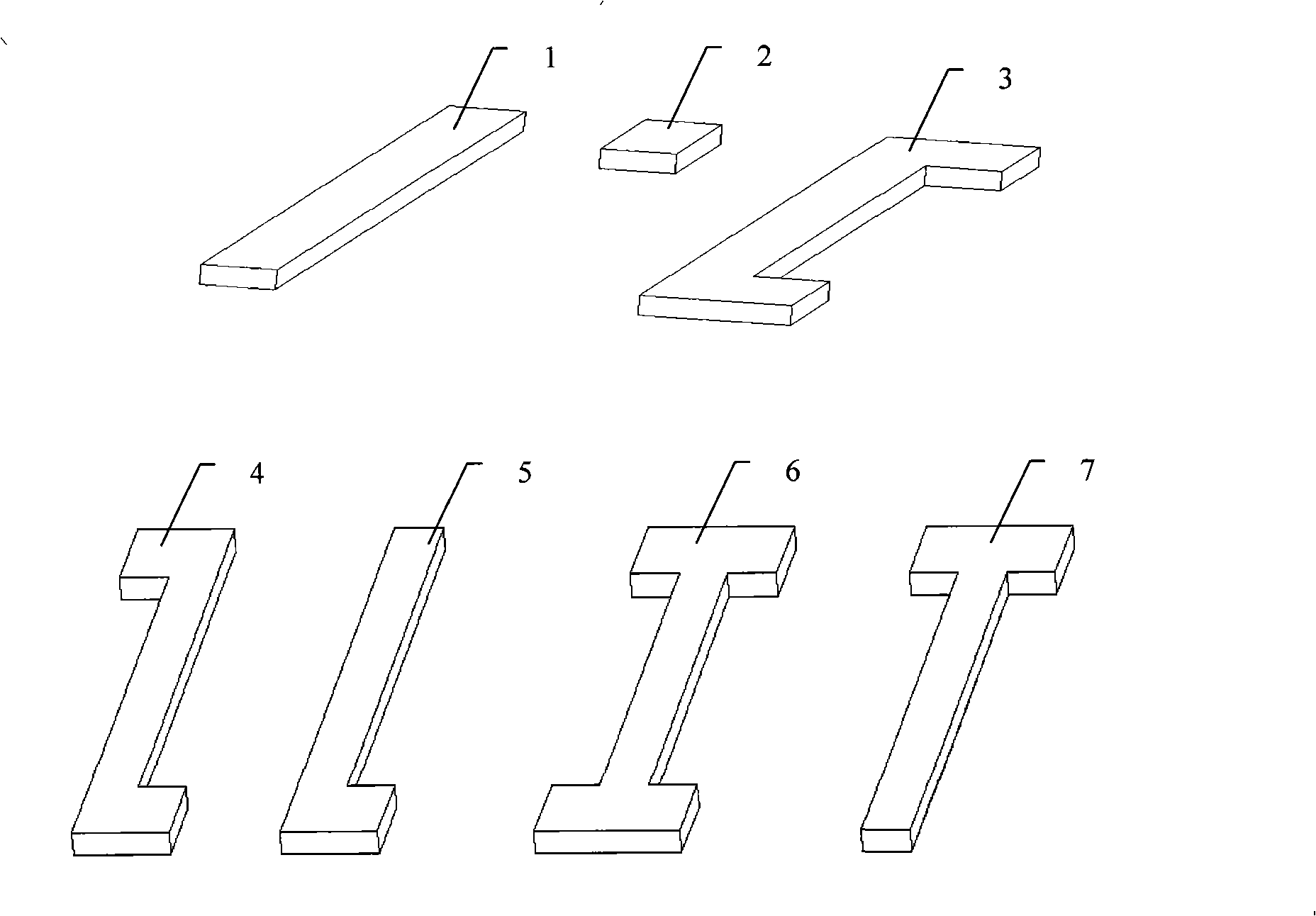

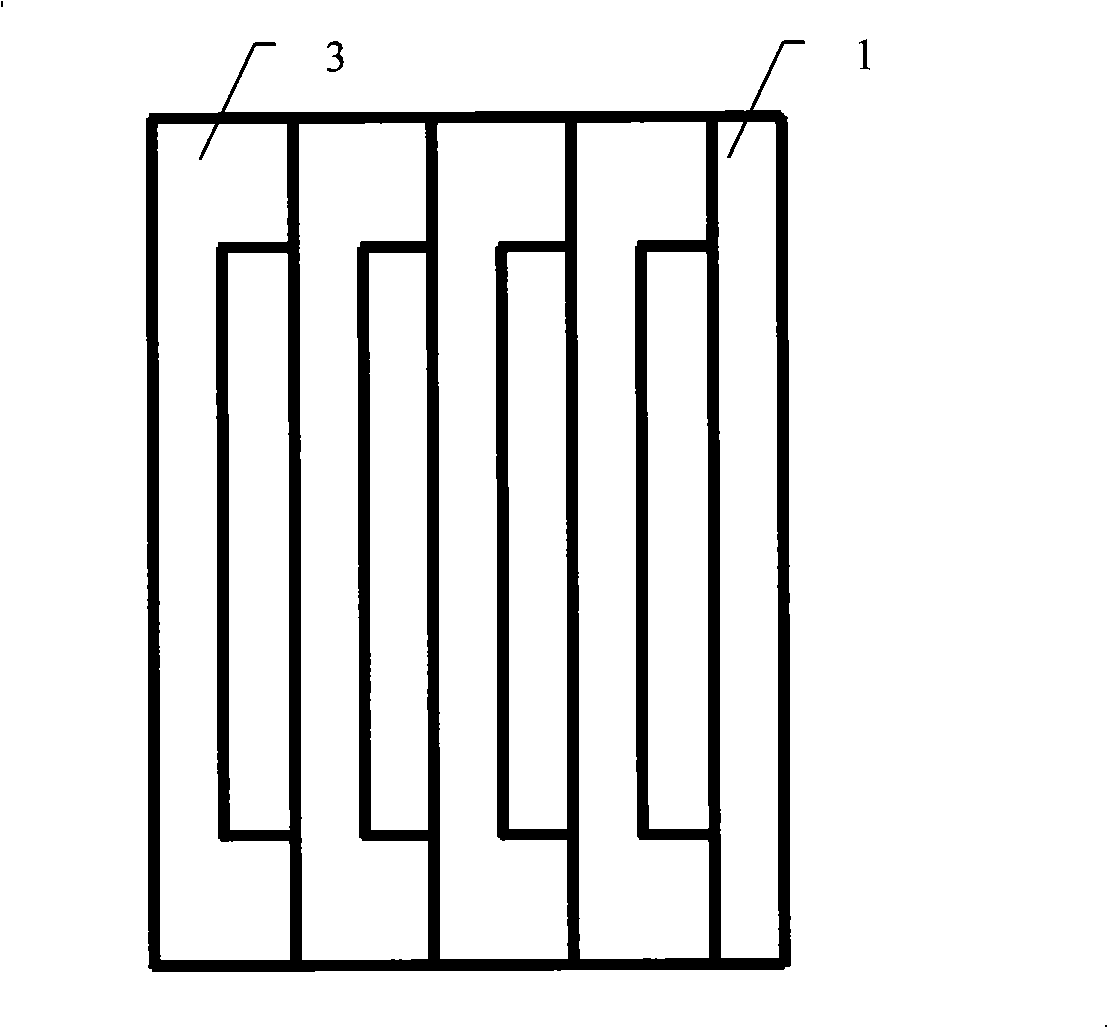

[0018] The wooden material is processed into L-shaped wooden strips and Z-shaped wooden strips. The length is determined according to the specifications of the board. The width of the wide part and the narrow part are 60mm and 30mm respectively, and the thickness is 10mm. braided like Figure 4 The L-Z type core material realizes the "integralization" of the core material, and is used to make the core material of the hollow thin wood board.

Embodiment 3

[0020] Thin MDF or thin particleboard is processed into a long strip unit member with a height of 80mm (the length is determined according to the specification of the hollow board), and the wooden material is processed into a short strip unit member with a height of 150mm×60mm×80mm. The strip unit members are glued together to form figure 2 The core material of long-short strip unit members is used to make the core material of thicker hollow panels (such as room partitions).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com