Lift traction device

An elevator traction and traction belt technology is applied in the field of traction devices for lifting articles, and can solve problems such as mutual interference of traction belts, overlapping of multiple traction belts, mutual interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

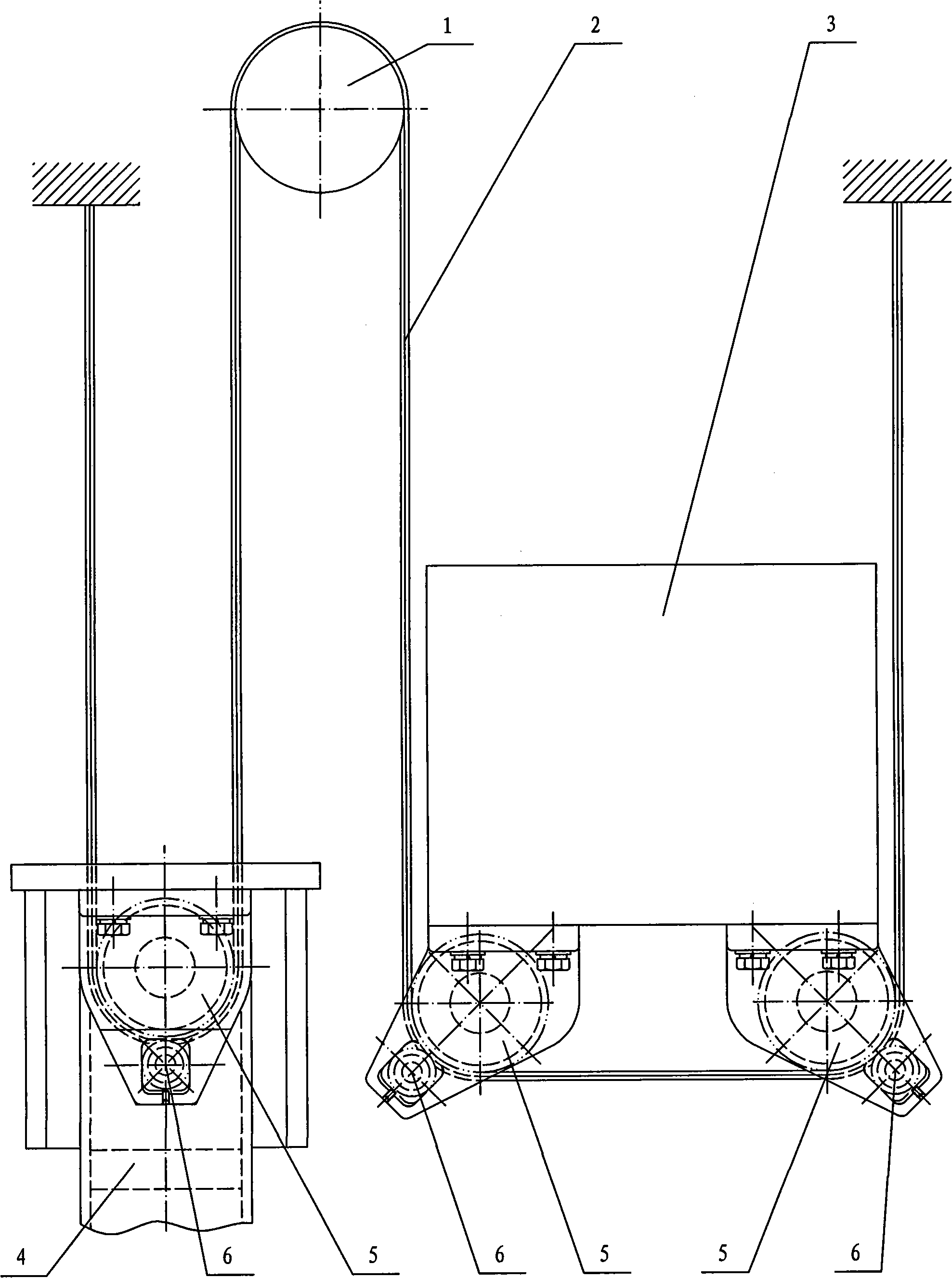

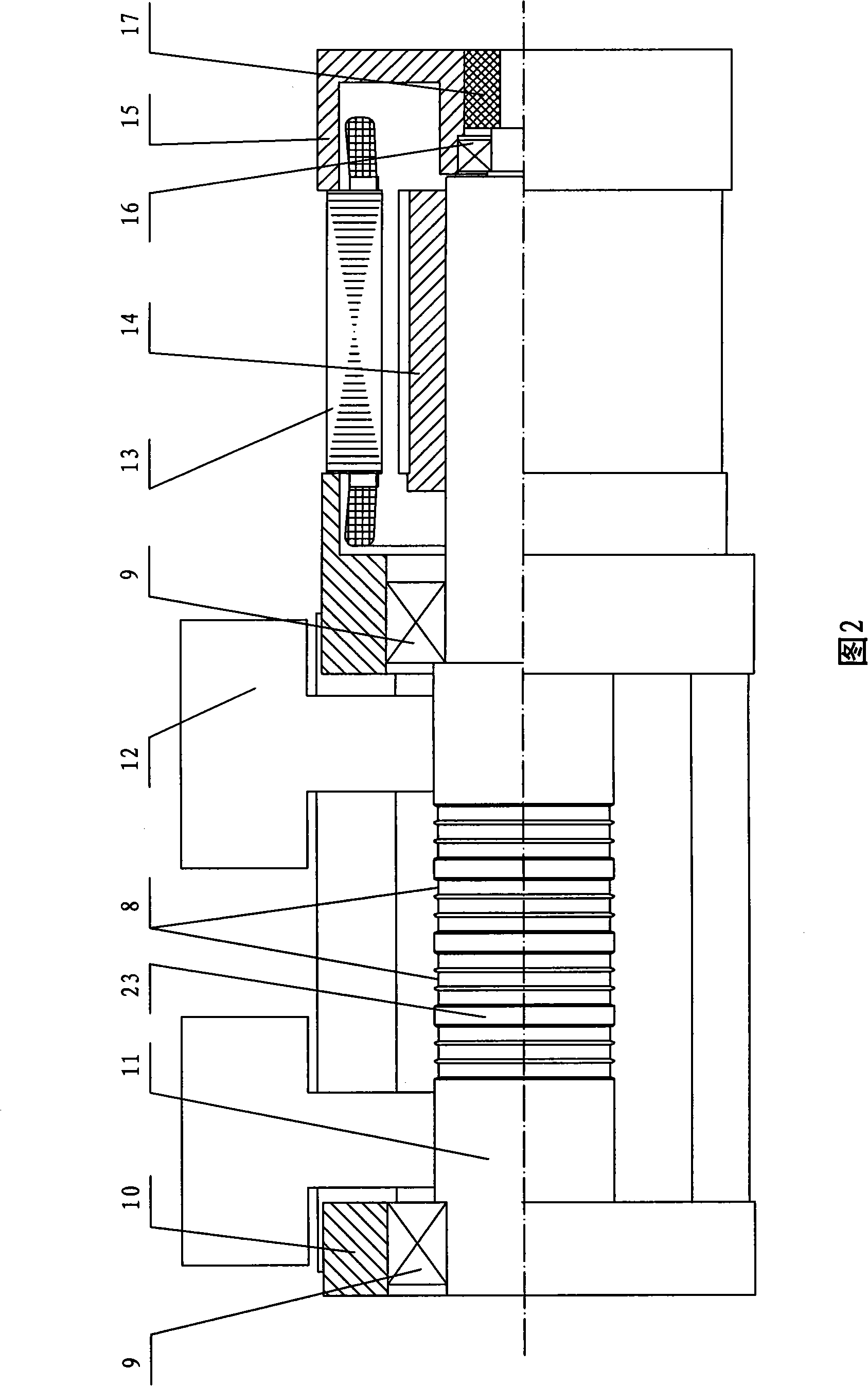

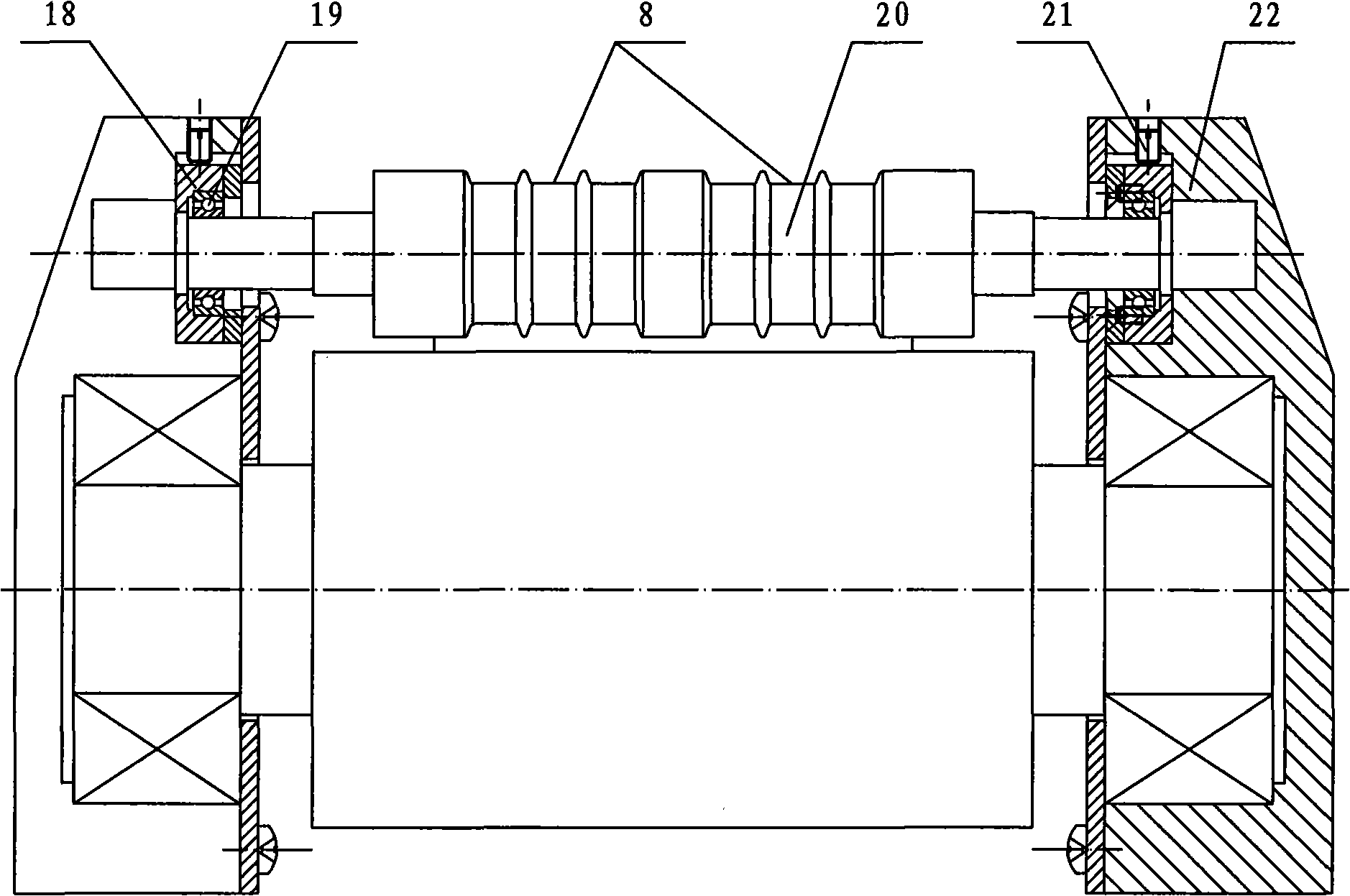

[0014] Depend on figure 1 It can be seen from the schematic structural diagram of the elevator traction device of the present invention that the elevator traction device comprises a traction machine 1 with a traction sheave 23, a traction belt 2 with protrusions 7 along the length direction, a car 3, Balance counterweight 4 and several transition wheels 5. The traction belt 2 is slip-fitted on the balance counterweight transition wheel 5, traction sheave 23, and car transition wheels 5. The two ends of the traction belt 2 are respectively fixed. In other words, one end of the traction belt 2 is fixed, and the other end passes through the balance counterweight transition wheel 5 , the traction sheave 23 on the traction machine 1 , and the car transition wheel 5 in sequence and then is fixed. Since the surface of the traction wheel 23...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com