Water-saving discharge-reducing consume-reducing continuous production method and device for nickel carbonate

A nickel carbonate and carbonate technology, applied in nickel carbonate and other directions, can solve the problems of excessive washing water, not being recycled, and low production efficiency, and achieve the effects of reducing washing water, shortening production cycle, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

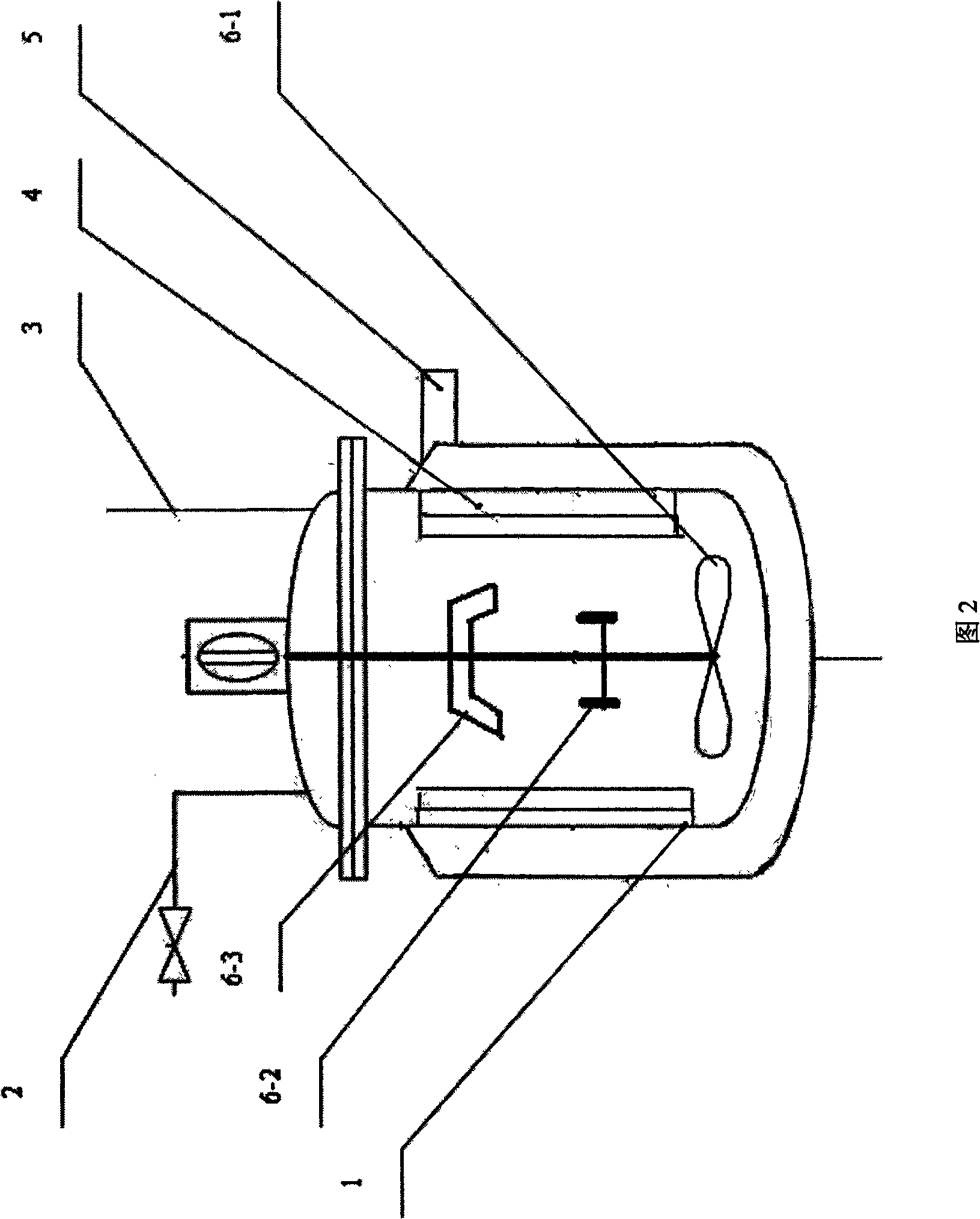

[0040] As can be seen from Fig. 2, realize the required reaction kettle of the method for continuous production of nickel carbonate of a kind of water saving, emission reduction and consumption reduction of the present invention, its kettle body 1 outside is provided with jacket, and its kettle cover is respectively provided with nickel sulfate aqueous solution feeding pipe 2, sodium carbonate aqueous solution feed pipe 3; still inboard is provided with baffle plate 4, two pairs of symmetrical feeding nozzles installed on the baffle plate 4 are connected with above-mentioned nickel salt solution feed pipe 2, sodium carbonate aqueous solution feed pipe 3 correspondingly respectively, The nickel salt solution and the sodium carbonate solution feeding nozzles are separated from each other; the three-layer structure agitator is arranged in the center of the kettle, from top to bottom are folded paddle agitator 6-3, frame agitator 6-2 And propeller type agitator 6-1, its kettle side...

Embodiment 2

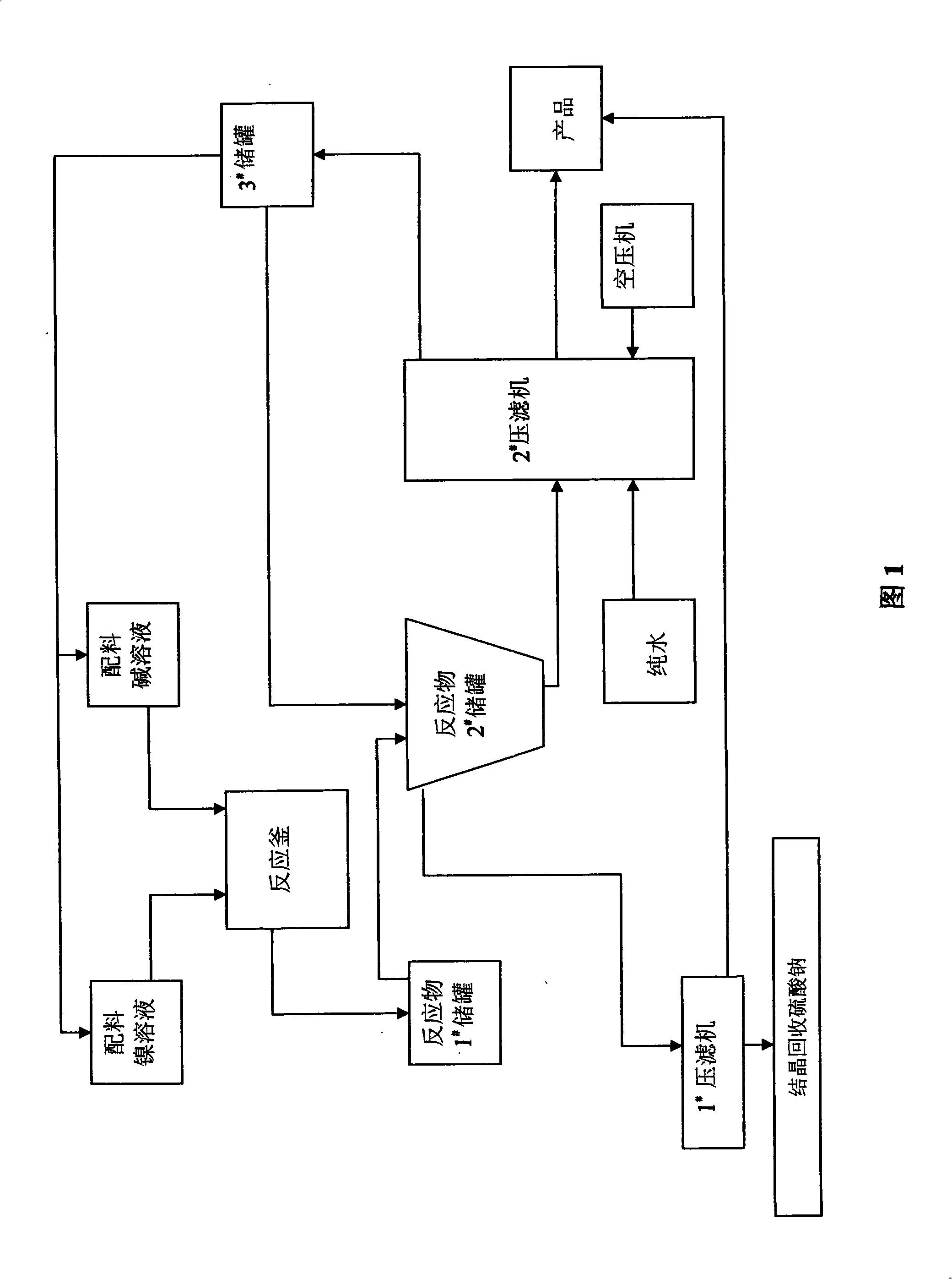

[0042] As can be seen from Fig. 1, a kind of water-saving, emission-reducing and consumption-reducing method of the utility model continuously produces nickel carbonate, and its steps are as follows:

[0043] Configure a nickel sulfate aqueous solution with a concentration of 40g / L and place it in the high-level tank;

[0044] Configure a sodium carbonate aqueous solution with a concentration of 10g / L and place it in a high-level tank;

[0045] The prepared nickel sulfate solution and sodium carbonate solution were added into the reaction kettle at a weight ratio of 1:1, and the temperature in the reaction kettle was controlled to be 50° C., the pH value was 7.0, and the stirring speed was 100 rpm.

[0046] The reactant flows out of the overflow pipe of the reactor into the reactant 1 # In the storage tank, aged at 60°C for 1 hour, stirred by an air pump into the reactant 2 # In the storage tank, stand still for 1-2 hours, when the alkali concentration of the supernatant is ...

Embodiment 3

[0055] Configure a nickel sulfate aqueous solution with a concentration of 120g / L and place it in the high-level tank;

[0056] The concentration of the configuration is 60g / L ammonium carbonate aqueous solution, which is placed in the high level tank;

[0057] As can be seen from Fig. 1, the above-mentioned prepared nickel sulfate solution and sodium carbonate solution are added in the reactor by 1: 3 weight ratio, and the temperature in the control reactor is 90 ℃, pH value 9.0, stirring speed 180rpm.

[0058] The reactant flows out of the overflow pipe of the reactor into the reactant 1 # In the storage tank, aged at 80°C for 3 hours, stirred by the air pump into the reactant 2 # Storage tank, stand still for 1 to 2 hours, when the concentration of ammonium carbonate in the supernatant is 15 to 80g / L, extract the supernatant to 1 # in the filter press;

[0059] from 3 # Pump water in storage tank to reactant 2 # The storage tank is stirred by an air pump, and is set in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap