Rocker of internal combustion valve mechanism

A valve train, internal combustion engine technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve the problems of increased cost and processing consumption, and achieve the effect of high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

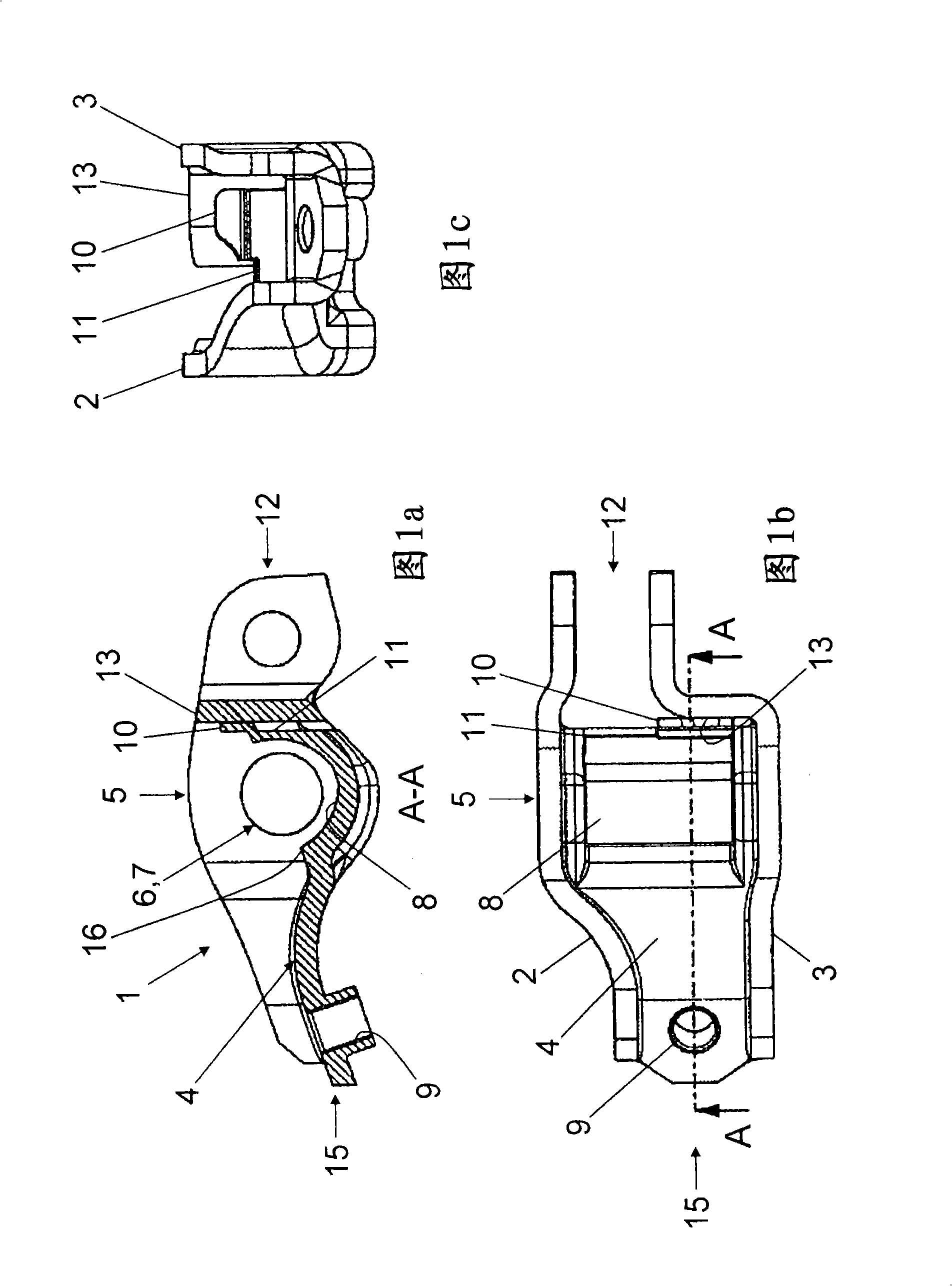

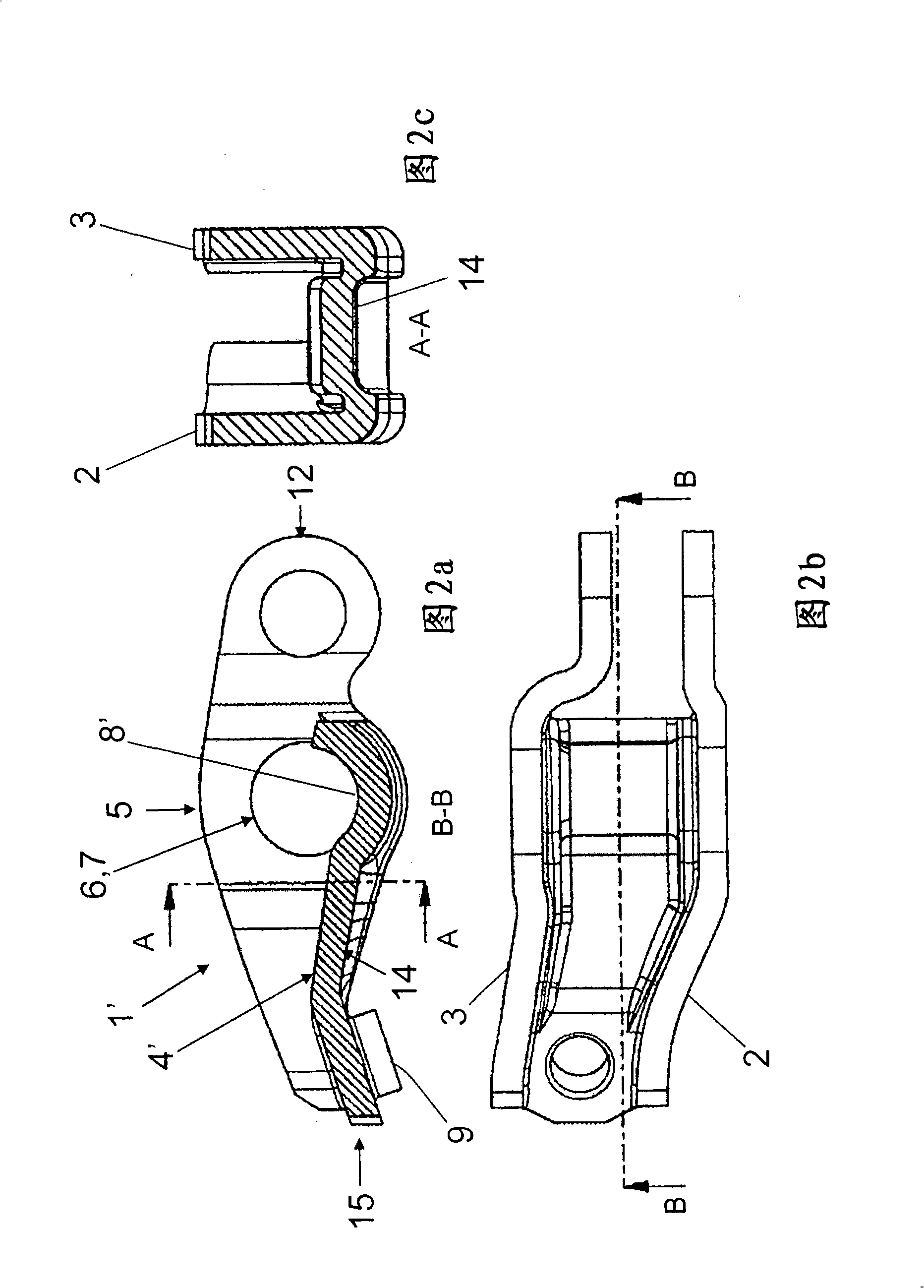

[0028] 1a to 1c show a rocker arm of a valve train of an internal combustion engine, which comprises a rocker body 1 produced in one piece from a stamped sheet steel. The rocker body 1 essentially comprises two side walls 2 and 3 which are connected to one another in the region of the lower side walls by a cross member 4 so as to form a U-like cross section.

[0029] In the middle part 5 of the side walls 2, 3 of the rocker arm body 1 there are two holes 6, 7 aligned with each other and designed as drilled holes for mounting the rocker arm on an unillustrated shaft or an equivalent center of rotation superior.

[0030] The rocker arm body 1 has a bent profile, or the rocker arm has an axial offset, wherein, in the direction of the cam-side rocker arm end 12, the side wall 2 is only slightly bent inwards here as an example, And the opposite side wall 3 inwards is basically at right angles, so that side walls 2 and 3 extend parallel to each other again at the end 12 of the rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com