Engine experimental stand

A test bench and engine technology, which is applied in the direction of engine testing, engine base, machine/structural component testing, etc., can solve the problems that the working conditions of the engine cannot be reproduced, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

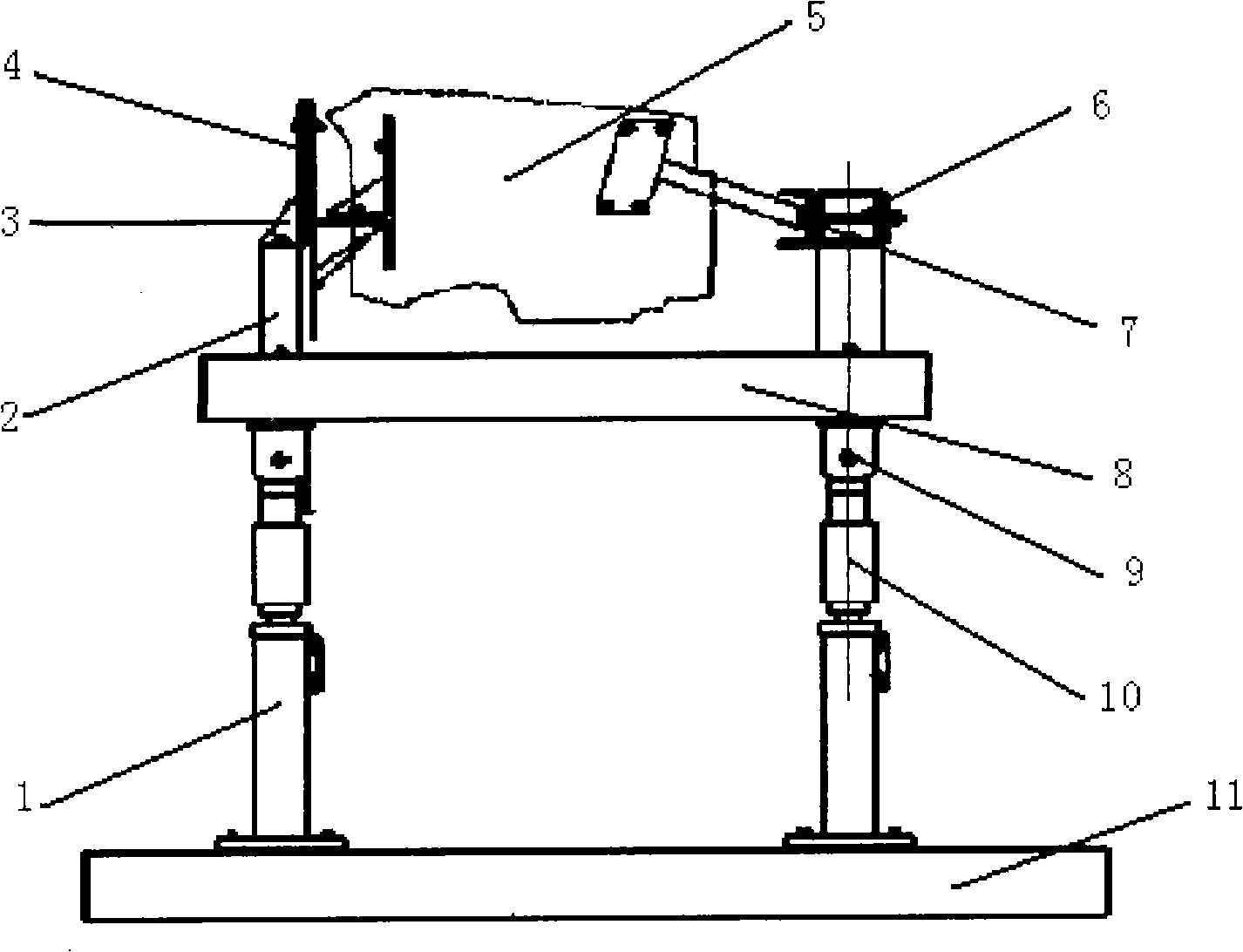

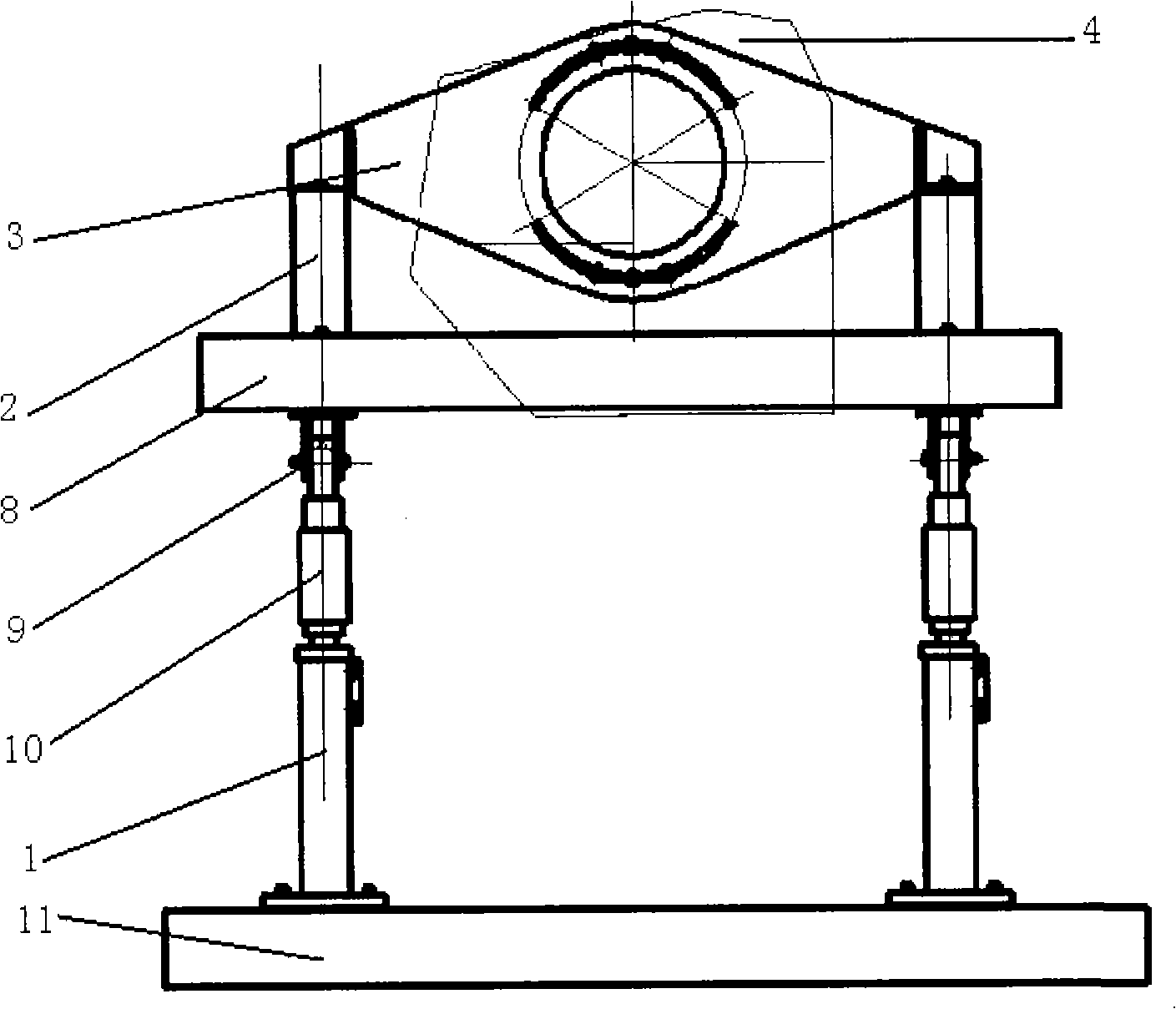

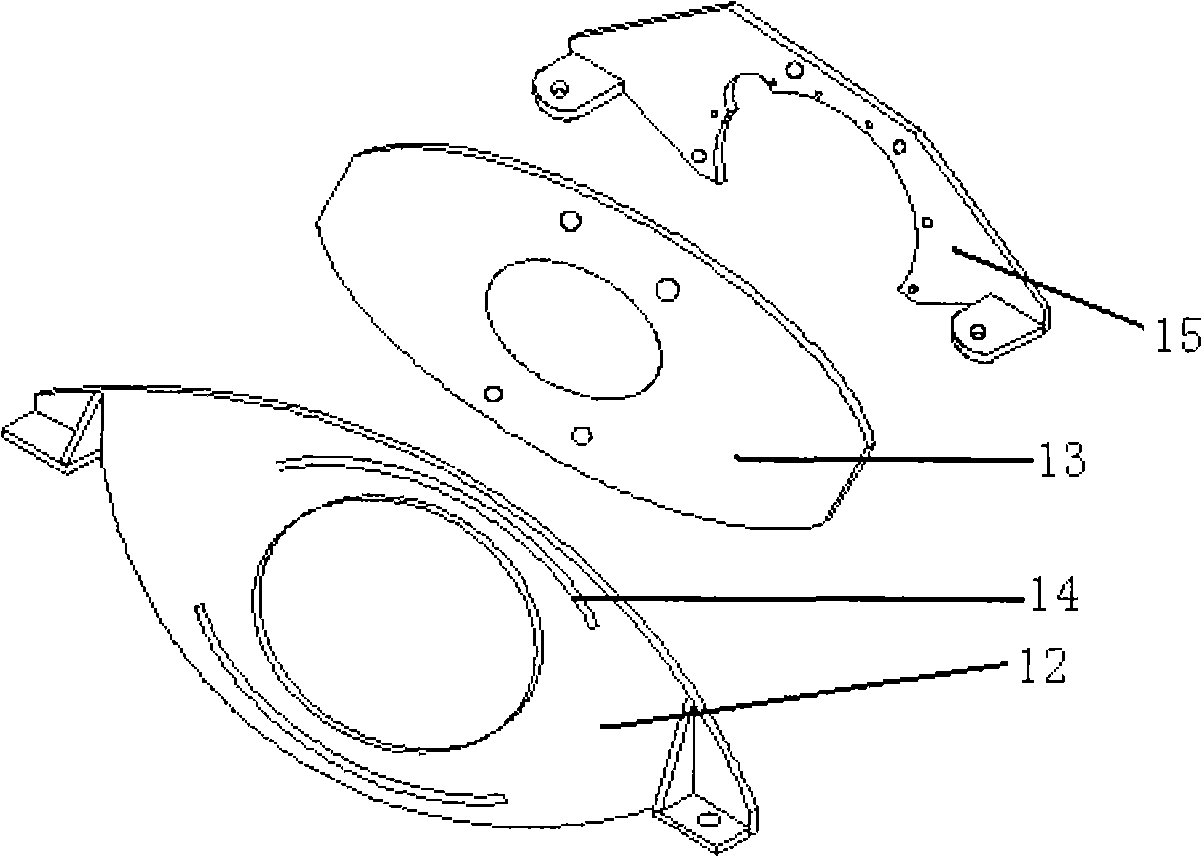

[0019] Example 1 in figure 1 , 2 , 3, 4, 5, 6, a kind of engine test bench, two channel steels with sliding grooves are fixed on the ground to form the chute floor 11, and 4 grooves are installed on the sliding grooves of the 11 channel steels on the chute floor Movable pillars 1, the upper part of these movable pillars 1 is connected with a height-adjusting pillar 10 that can be adjusted in height. The height-adjusting pillar 10 is a two-stage structure of stud screw holes, which is adjusted by screwing the studs into the screw holes of the movable pillars. Then lock it by locking bolt 18. The front and rear inclination between the accessories of the engine and the flywheel can be adjusted by adjusting the distance of 4 movable pillars 1 and the height of the raised pillar 10. By measuring the height difference of 4 movable pillars 1 and the distance between them, the engine The angle of inclination before and after can be calculated by formula. Connected above the height-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com