An electronic transformer

An electronic transformer and external circuit technology, applied in the direction of transformer/inductor magnetic core, transformer/inductor coil/winding/connection, electrical component structure association, etc., can solve problems such as instability, temperature rise, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

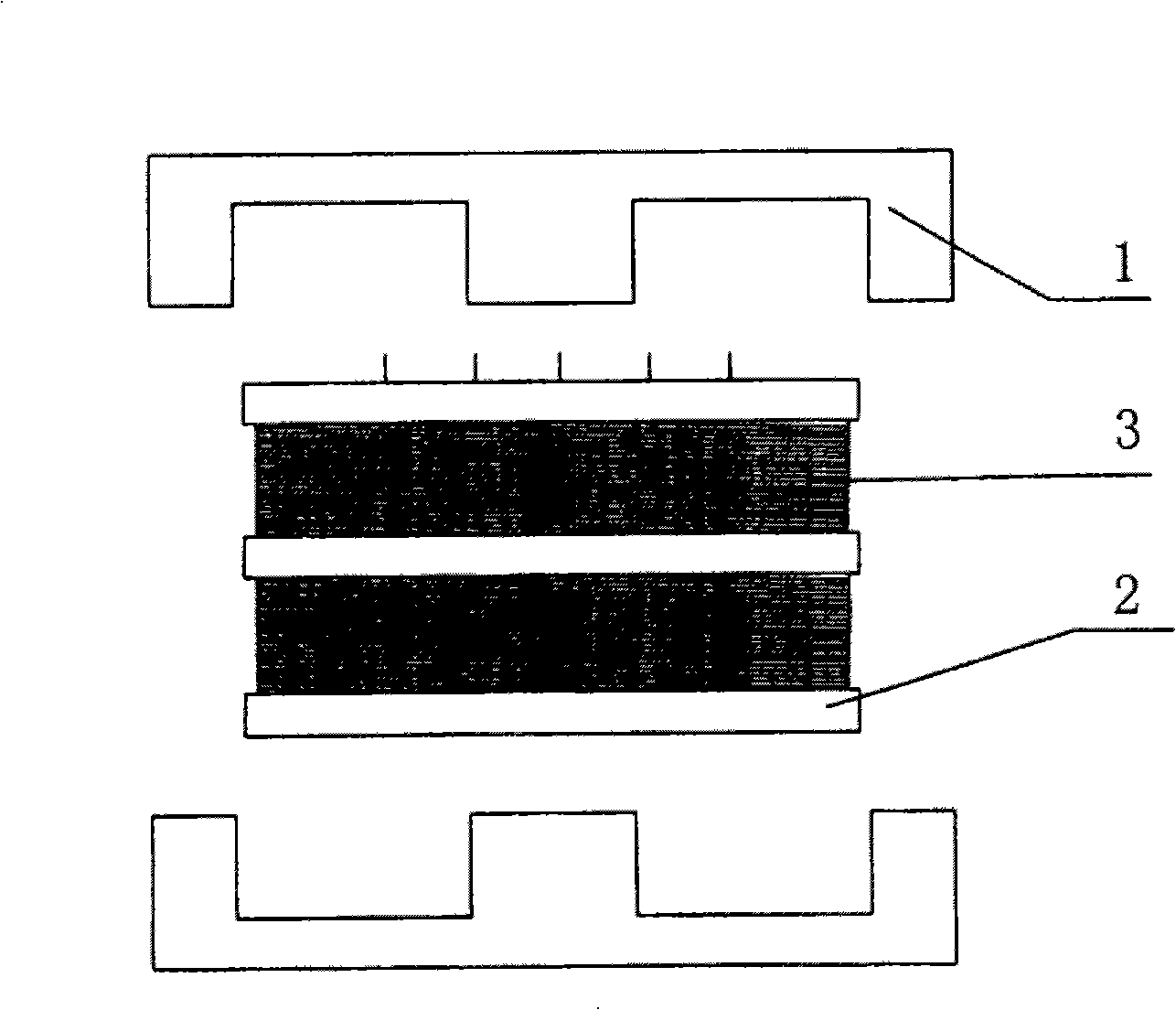

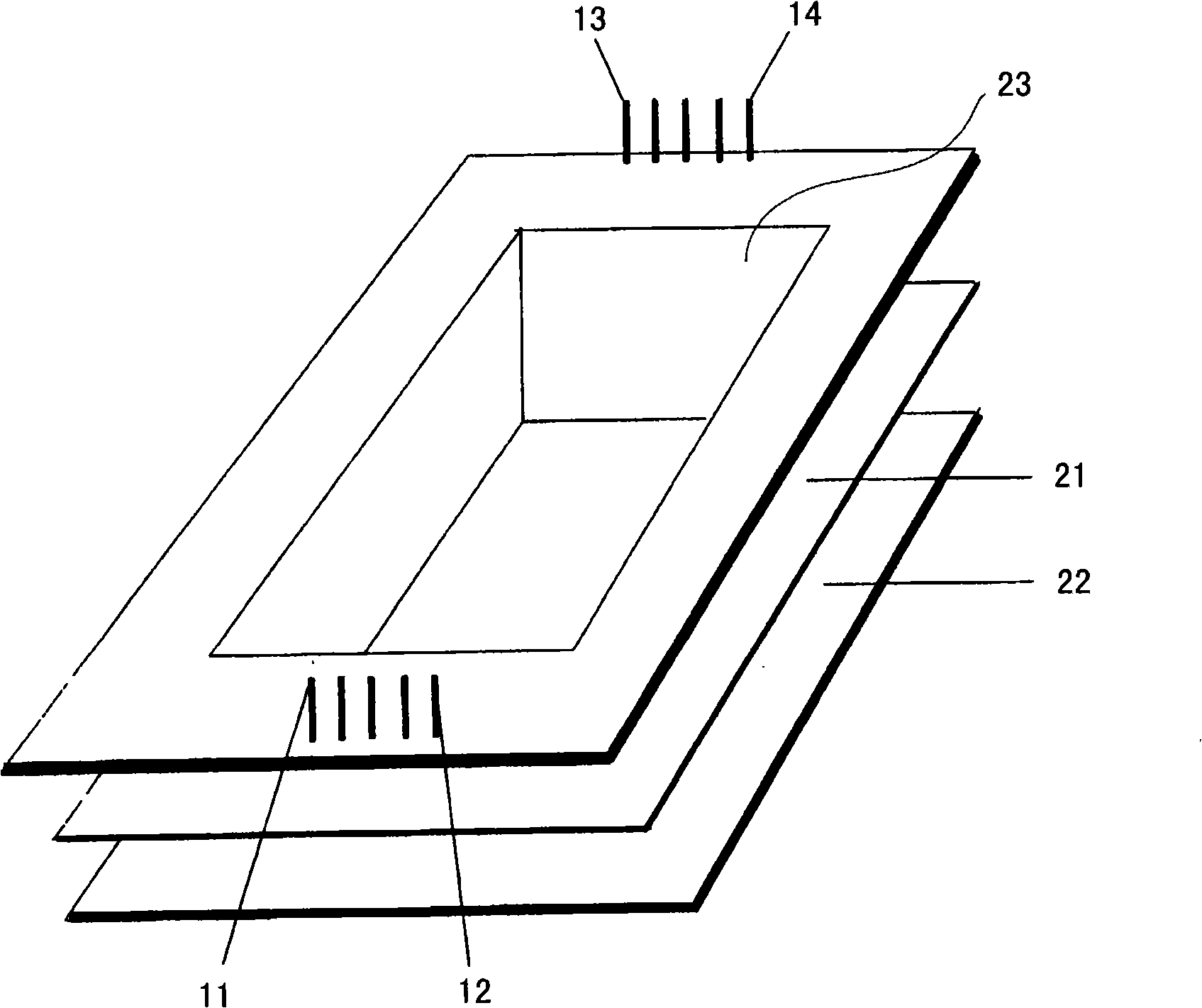

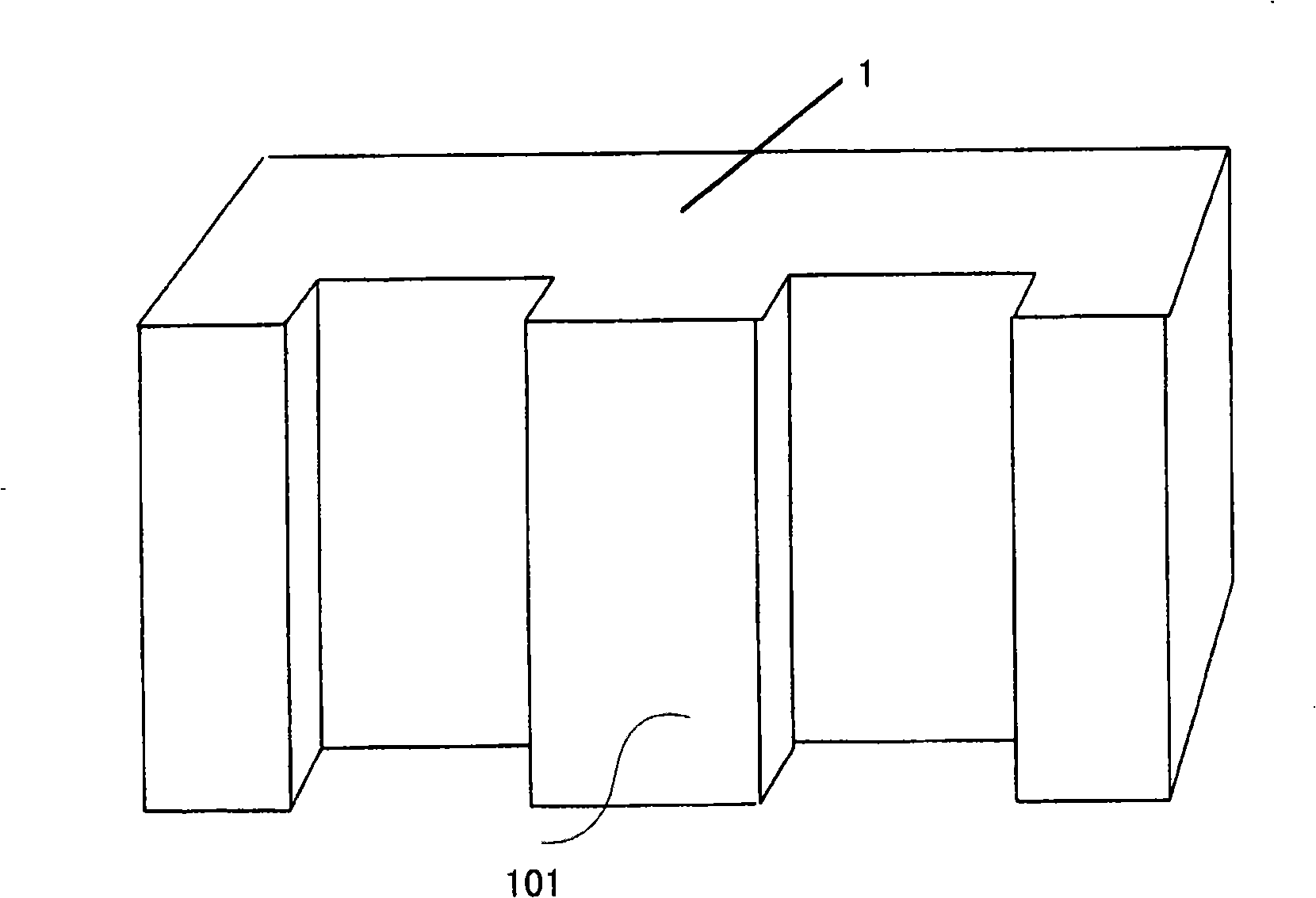

[0017] Please see attached figure 1 As shown, the electronic transformer of the present invention includes a magnetic core 1, a bobbin 2 and a coil 3, wherein the magnetic core 1 is formed by two E-shaped magnetic cores connected in a Japanese-shaped combination, and the central column of the magnetic core 1 is inserted into the bobbin In 2, the outer frame of the magnetic core 1 encloses the winding frame 2 and the coil 3, and the cross section of the winding frame 2 is a back-shaped structure, which is divided into upper and lower layers of winding slots 21 and 22, and the coil 3 is respectively wound on the wire slots 21 and 22 within. Hollow through-holes 23 are provided on the top and bottom surfaces of the bobbin frame 2, and lead joints 11-14 are arranged at opposite positions on the bottom surface of the bobbin frame 2, and the joints of the coils are respectively welded on the lead joints.

[0018] When assembling the electronic transformer of the present invention, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com