Food forming device and foods producing system having the device

A food molding and production system technology, applied in the direction of forming/molding baked waffles, etc., can solve the problems that are difficult to motivate consumers to make custom cakes, food quality, instability, etc., to increase the desire to buy, The effect of maintaining quality and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The implementation of the present invention is described below through specific examples, and those skilled in the art can easily understand other advantages and effects of the present invention from the content disclosed in this specification.

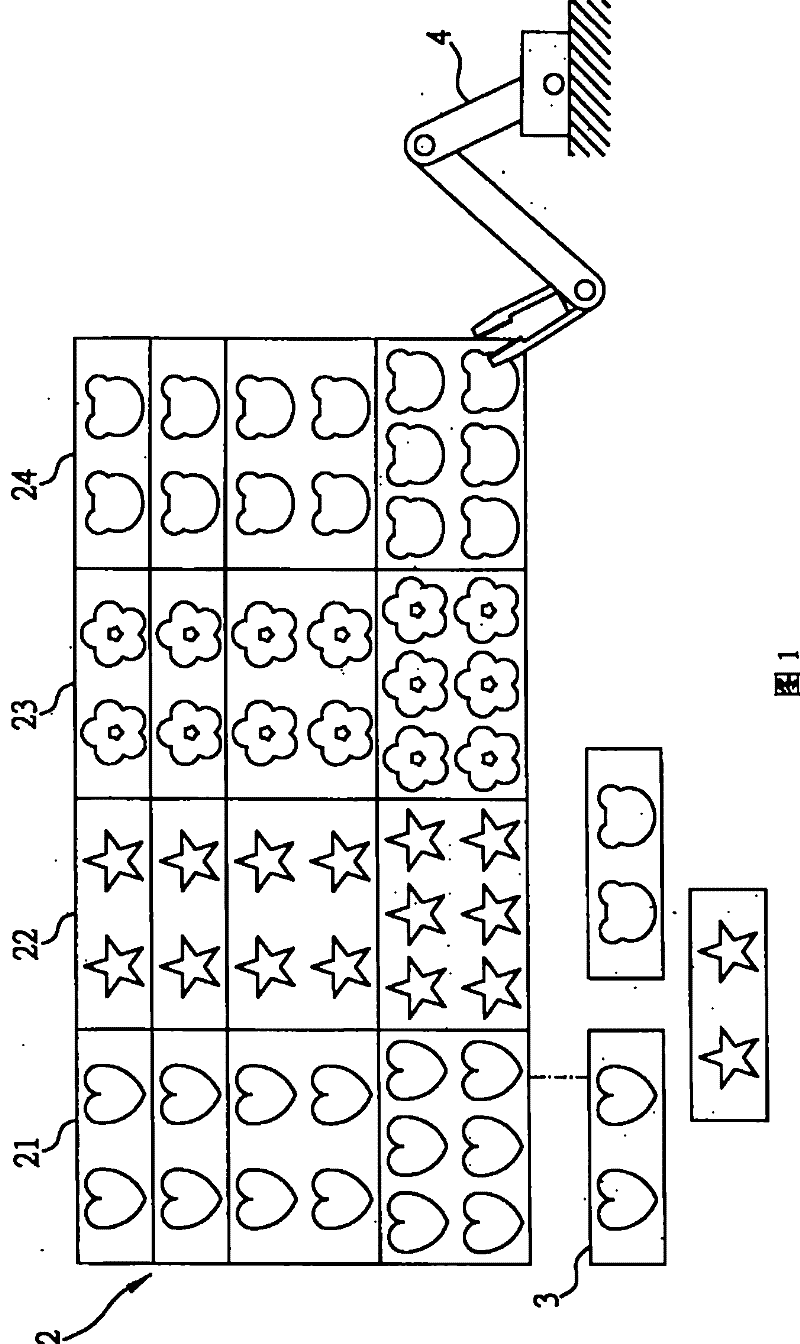

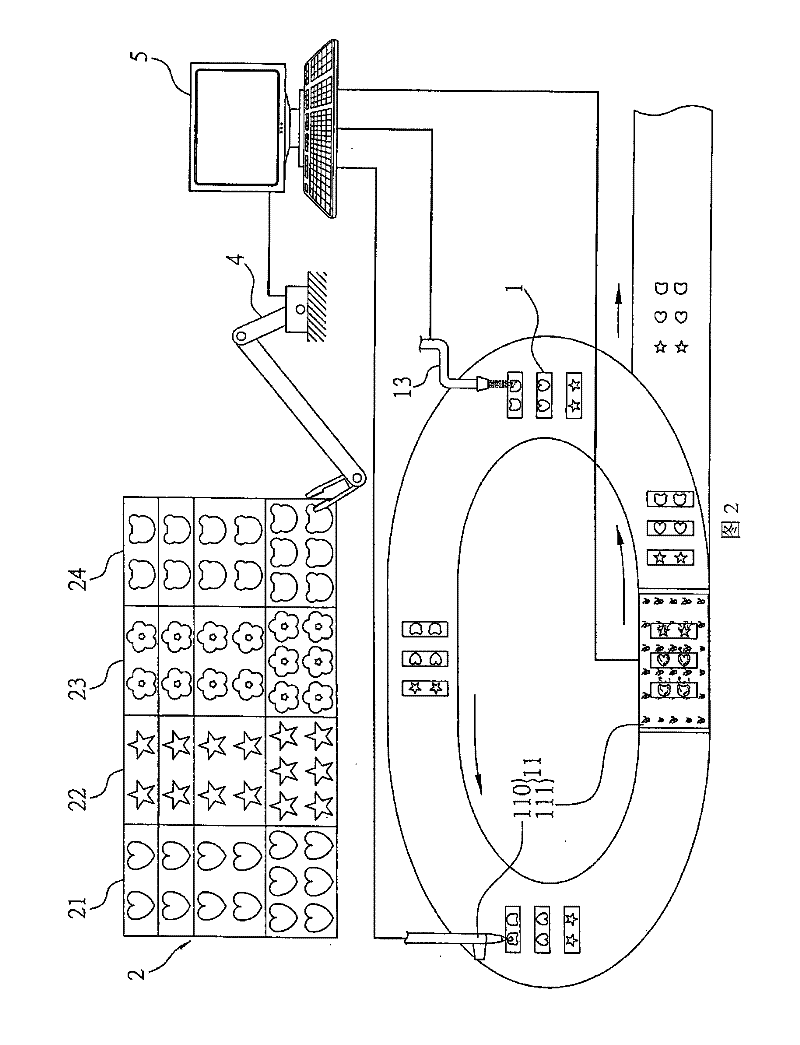

[0049] see figure 1 , the food molding device of the present invention includes a mold unit 2, which has a variety of molds, such as a mold 21 with a heart-shaped cavity, a mold 22 with a star cavity, a mold 23 with a quincunx cavity, and a mold with an animal shape. The cavity mold 24, however, in addition to the difference in the shape of the mold, the mold can also have a difference in the number of cavities, such as the mold with 2, 4, 6 or multiple cavities in this embodiment. Of course, the shape and number of mold cavities applicable to the mold of the present invention are not limited to those shown in this embodiment, but may be of various other mold cavity shapes or have other numbers of mold cavities. In addition, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com