Perfumed laser-jet paper

A laser paper, laser technology, applied in papermaking, paper coating, textiles and papermaking, etc., can solve the problem of not seeing the report of fragranced laser paper and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

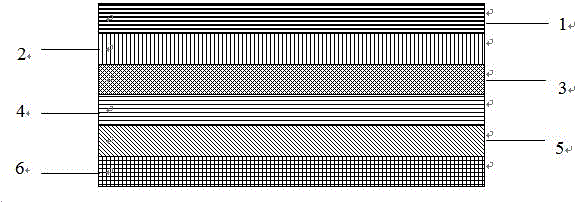

Image

Examples

Embodiment 1

[0046] (1) Preparation of mint-flavored paint: Take 23kg of polyvinyl alcohol 1788 aqueous solution, 2kg of natural peppermint flavor extract and 10.85kg of water in sequence, add them to the reaction kettle, stir for 10min, then raise the temperature to 40°C, add 0.15kg of succinic aldehyde, continue Stir for 4 hours; add 60 kg of water-based acrylic copolymer emulsion to the reaction kettle, and stir for 10 minutes; sequentially add 2.5 kg of Dispers740 wetting agent and 1.5 kg of TEGO Airex 902w defoamer to the reaction kettle, and stir for 20 minutes to obtain a mint-flavored coating .

[0047] (2) Preparation of scented varnish: take 20kg of cross-linked acrylate emulsion, directly add 80kg of mint scented paint, stir for 1 hour, and prepare mint scented varnish.

[0048] (3) Preparation of laser transfer film: Put the polyethylene terephthalate base film into the unwinding device, turn on the unwinding device, the original film is coated with ordinary laser coating of se...

Embodiment 2

[0052] (1) Preparation of coffee-flavored paint: Take 35kg of polyvinyl alcohol 1788 aqueous solution, 0.1kg of natural coffee essence extract and 30kg of water in sequence, add them to the reaction kettle, stir for 10min, then raise the temperature to 50°C, add 0.08kg of succinic aldehyde, continue Stir for 4 hours; add 33.32 kg of water-based acrylic copolymer emulsion to the reaction kettle, and stir for 10 minutes; sequentially add 1 kg of Dispers740 wetting agent and 0.5 kg of TEGO Airex 902w defoamer to the reaction kettle, and stir for 20 minutes to obtain a coffee-flavored coating .

[0053] (2) Flavoring of laser paint: Take 35kg of acrylate emulsion, directly add 65kg of coffee aroma laser paint, stir for 1 hour, and prepare coffee aroma laser paint.

[0054] (3) Preparation of laser transfer film: Put the polyethylene terephthalate base film into the unwinding device, open the unwinding device, the original film is coated with coffee-flavored laser coating by the co...

Embodiment 3

[0058] (1) Preparation of sweet orange flavor paint: Take 30kg of polyvinyl alcohol 1788 aqueous solution, 1kg of natural coffee essence extract and 15.9kg of water in sequence, add them to the reaction kettle, stir for 10min, then raise the temperature to 60°C, add 0.1kg of succinic dialdehyde, Continue to stir for 4 hours; add 50 kg of water-based acrylic copolymer emulsion to the reactor, and stir for 10 minutes; sequentially add 1.8 kg of Dispers740 wetting agent and 1.2 kg of TEGO Airex 902w defoamer to the reactor, and stir for 20 minutes to obtain coffee aroma coating.

[0059] (2) Flavoring of the back coating solution: take 1kg of polyvinylidene chloride emulsion, directly add 99kg of sweet orange fragrance paint, mix and stir for 1 hour, and prepare the sweet orange fragrance back coating solution.

[0060] (3) Preparation of laser transfer film: Put the polyethylene terephthalate base film into the unwinding device, turn on the unwinding device, and the original fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com