Method for preparing cold water dispersion type microcapsule powder

A technology of microcapsule powder and dispersion type, which is applied in the field of preparation of cold water dispersion type microcapsule powder, can solve the problems of uncontrollable product quality, residual organic solvent, rarely used, etc., and achieves low surface oil content and high oil load. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

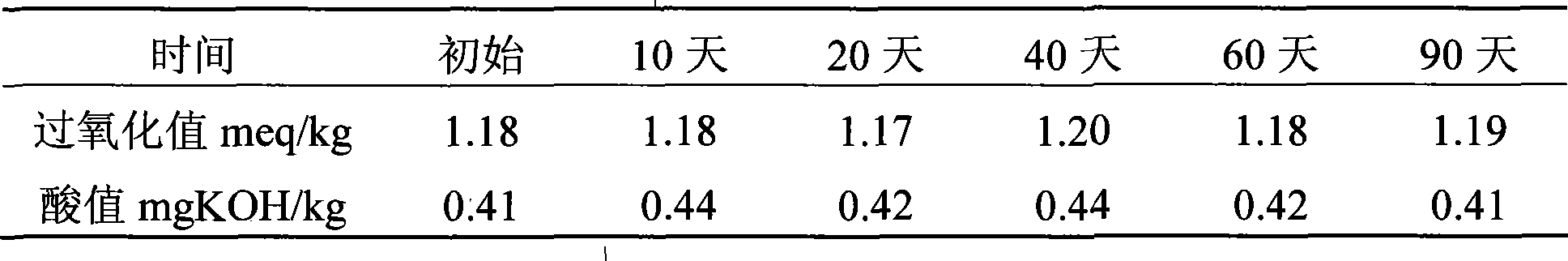

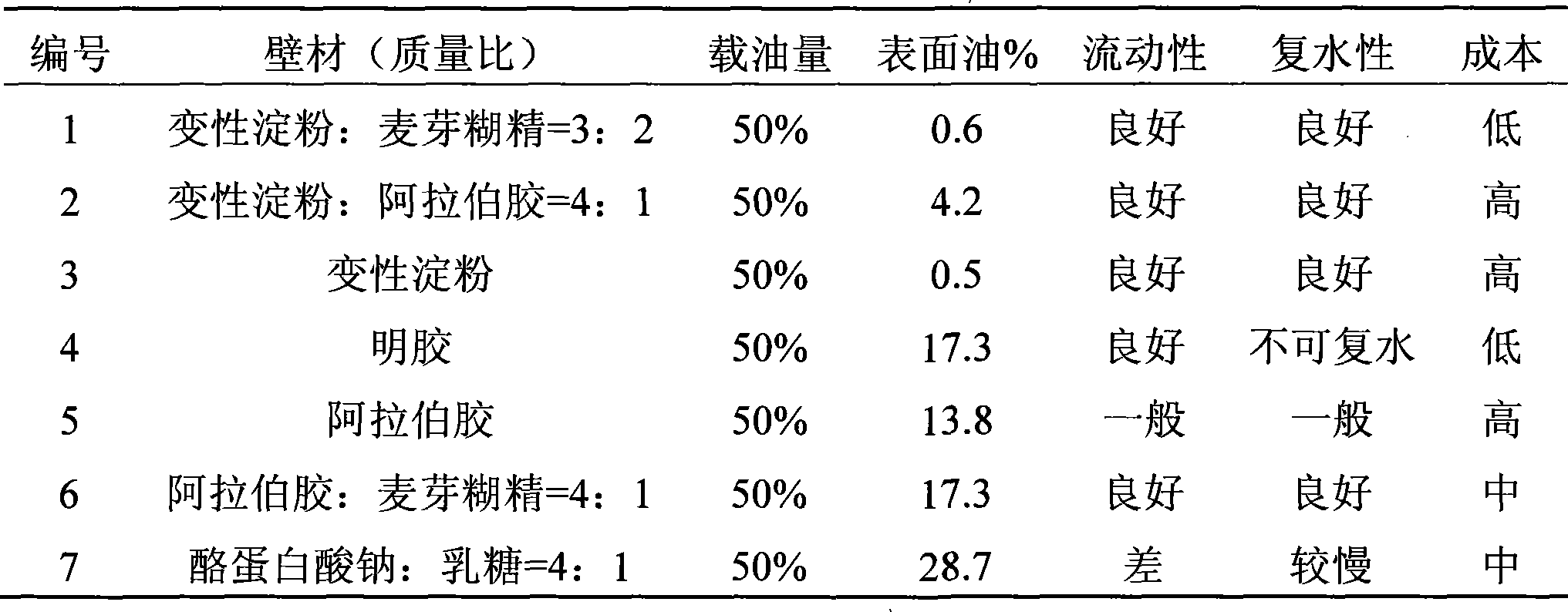

[0072] Heat 50 g of borage oil in a water bath at 50° C., add 0.1 g of natural mixed vitamin E and fully stir to obtain an oil phase. The water phase is composed of 30g of modified starch, 20g of maltodextrin (national standard MD150), and 100g of water, and the temperature of the water phase is 25°C. Add the oil phase to the water phase, emulsify with a high-speed shearing machine for 10 minutes, and then use a high-pressure homogenizer to homogenize the emulsion twice, so that the particle size of the oil droplets is less than 1 μm. The homogenization pressure used: low pressure 16MPa, high pressure 50MPa. The emulsion obtained above was dried in a spray drying tower, and the spray drying conditions were as follows: the inlet air temperature was 180°C, and the outlet air temperature was 80°C. The particle size of the microcapsules after drying is 80-160 mesh, the oil carrying capacity of the product is 50%, the surface oil content is 0.68%, the rehydration stability is good...

Embodiment 2

[0075] 44g of modified starch, 1.1g of polyglycerol fatty acid ester and 30g of sucrose were placed in a 250ml container, 100ml of purified water was added thereto, and the mixture was stirred rapidly at 25°C to form a matrix solution. At 55°C, 1.6g of low-alpha mixed tocopherols were fully mixed into 48g of lutein ester oil suspension (content 15%, crystal particles in it were less than 2μm). Then slowly pour the oil phase mixture into the above-mentioned matrix solution for high-speed shear emulsification, and the emulsification speed of the shearer is 8000-12000r / min. The average particle size of the discontinuous phase of the emulsion formed at this time is about 4 μm. Then the emulsion is circulated and homogenized under high pressure at 50Mpa until the average particle size of the discontinuous phase in the matrix solution is 1000nm or smaller. Finally, the emulsion is spray-dried to obtain a cold-water dispersible lutein ester microcapsule powder with a content of abou...

Embodiment 3

[0079] 44g of modified starch, 1.1g of polyglycerol fatty acid ester and 30g of sucrose were placed in a 250ml container, 100ml of purified water was added thereto, and the mixture was stirred rapidly at 25°C to form a matrix solution. At 55°C, 1.6g of low-alpha mixed tocopherols were fully mixed into 48g of lutein ester oil suspension (content 15%, crystal particles in it were less than 2μm). Then slowly pour the oil phase mixture into the above-mentioned matrix solution for high-speed shear emulsification, and the emulsification speed of the shearer is 8000-12000r / min. The average particle size of the discontinuous phase of the emulsion formed at this time is about 4 μm. Then the emulsion is circulated and homogenized under high pressure at 50Mpa until the average particle size of the discontinuous phase in the matrix solution is 1000nm or smaller. , the emulsion is sprayed through a low-speed rotating atomizing disc to form droplets of 180-400 μm, and then fed into cold mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com