Method and apparatus for monitoring thermal load of vehicle clutch

A clutch and thermal load technology, applied in clutch, transmission control, components with teeth, etc., can solve problems such as increased control cost, increased sensor power, suboptimal temperature model, etc., to avoid defects and avoid thermal shocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

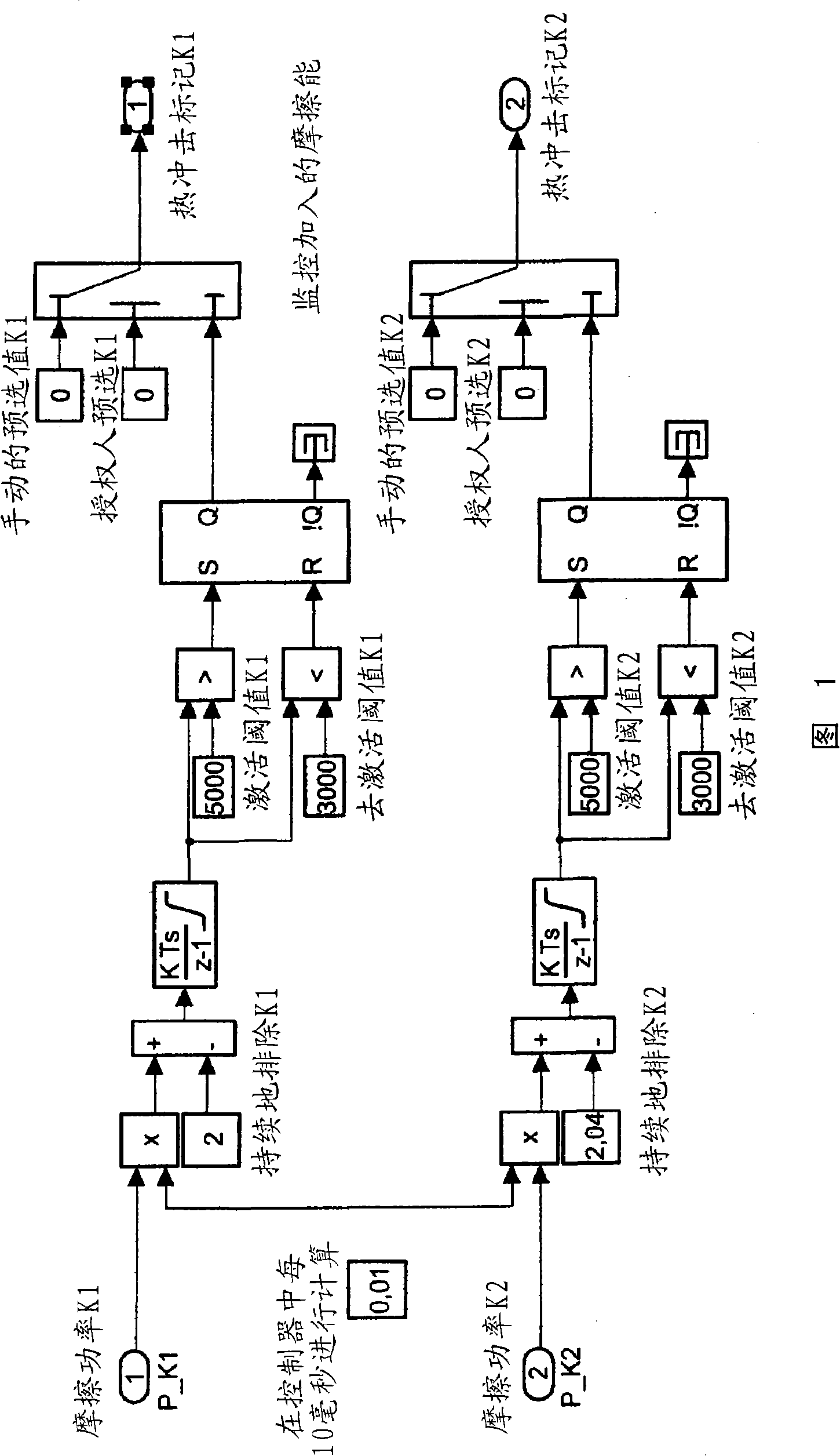

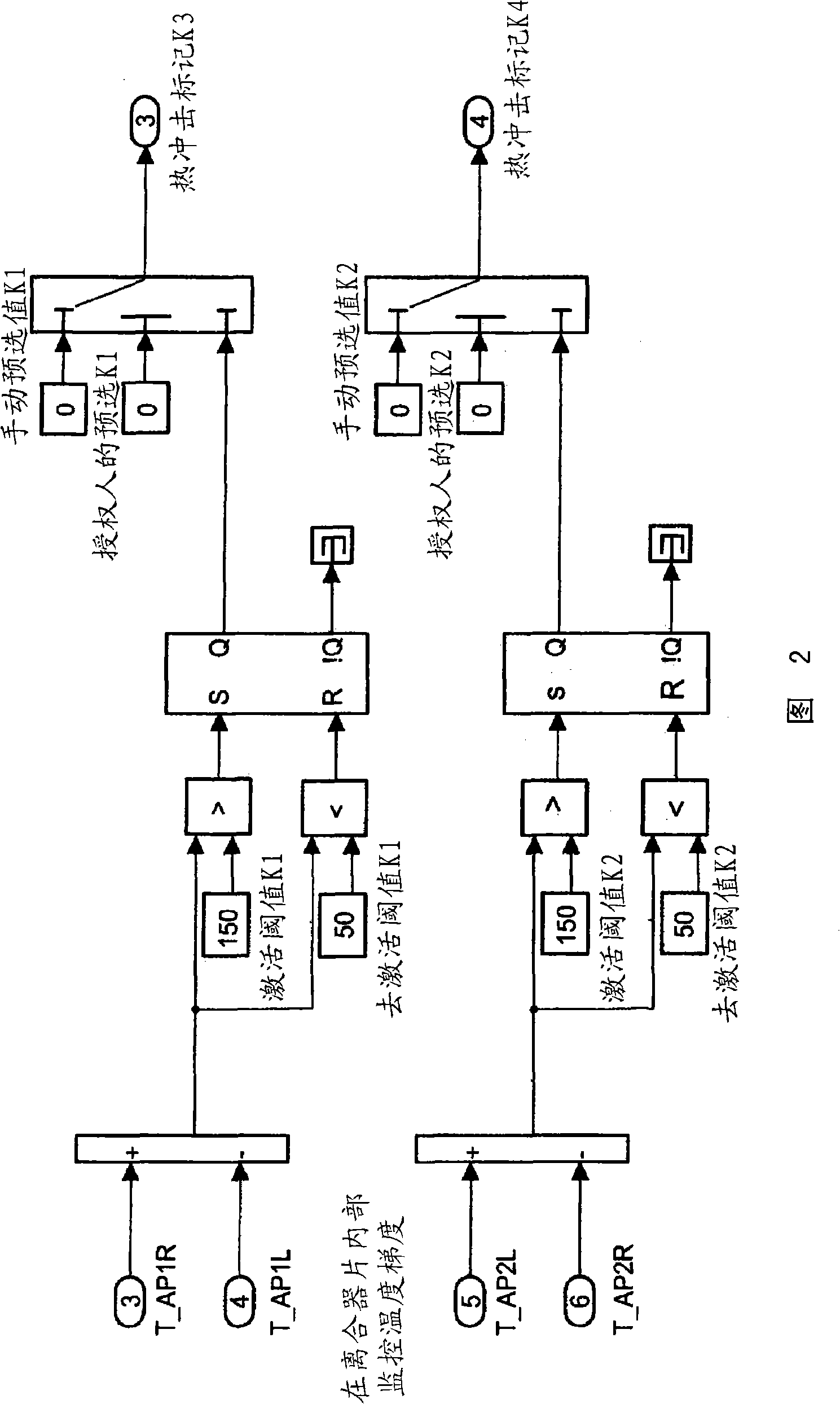

[0013] FIGS. 1 and 2 firstly show a method for monitoring the thermal load of a clutch (not shown in detail) of a motor vehicle (not shown in detail here).

[0014] 1 and 2 show in particular the circuit sequence of a corresponding device operating in this way. These methods are used in particular to avoid clutch thermal shock, for example they implement the dual clutches of a dual clutch transmission. In this case, the thermal load of the clutch is calculated and / or determined, wherein a controller, also not shown in detail here, is provided for controlling the clutch to be controlled in order to disconnect the clutch in time when the thermal load exceeds a threshold value.

[0015] The above-mentioned drawbacks are now thus avoided, and with reference to FIG. 1 , the rotational speed of the engine and / or the torque of the engine and / or the rotational speed of the transmission input shaft are determined and / or calculated (this can be done, for example, by means of correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com