Damping opposite-thrust type gas wave refrigerating machine

A gas wave refrigerator and hedging technology, applied in refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems of energy dissipation, reduced refrigeration efficiency, long oscillation tube length, etc., and achieve improved use efficiency and refrigeration efficiency. Improved and reduced mechanical vibration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

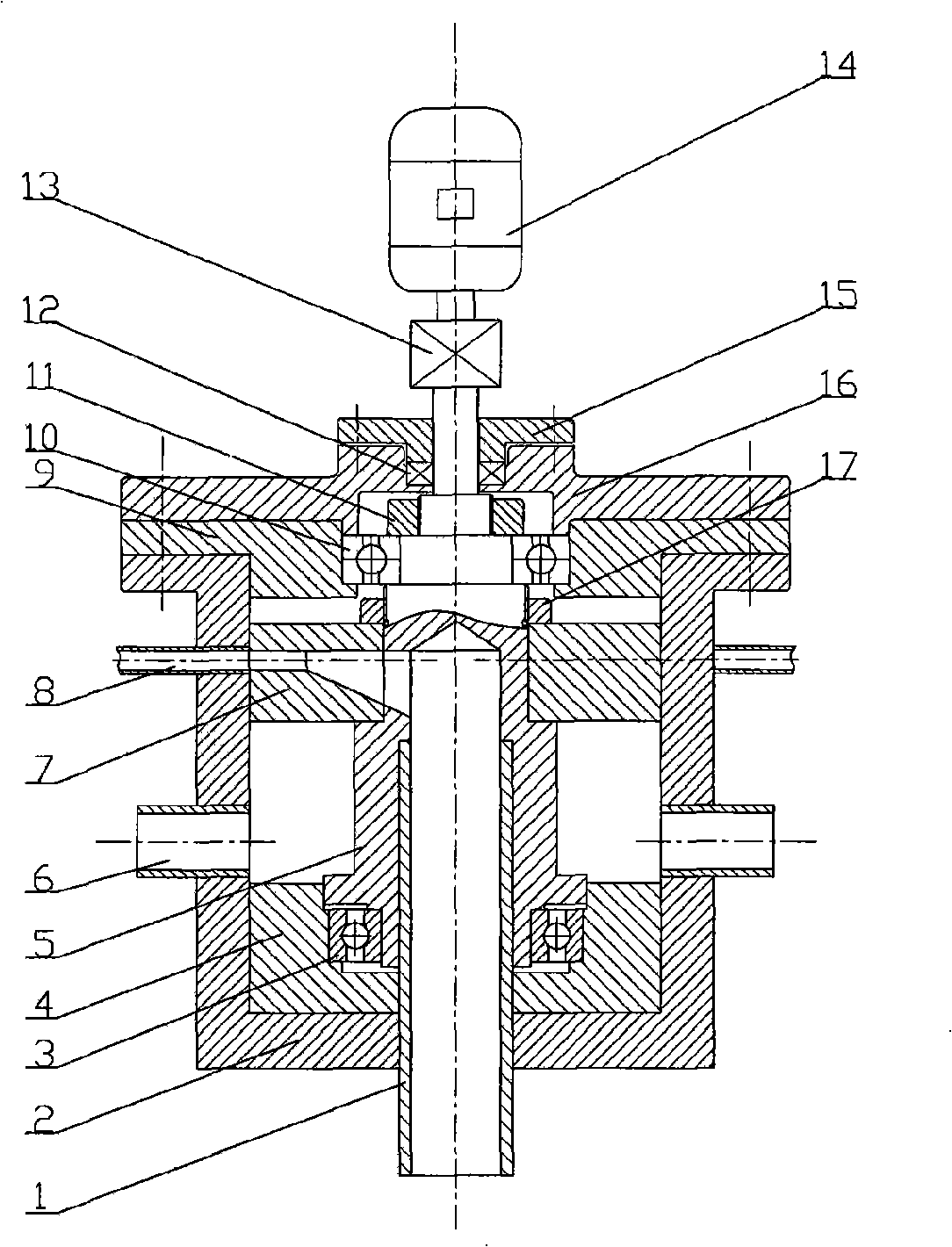

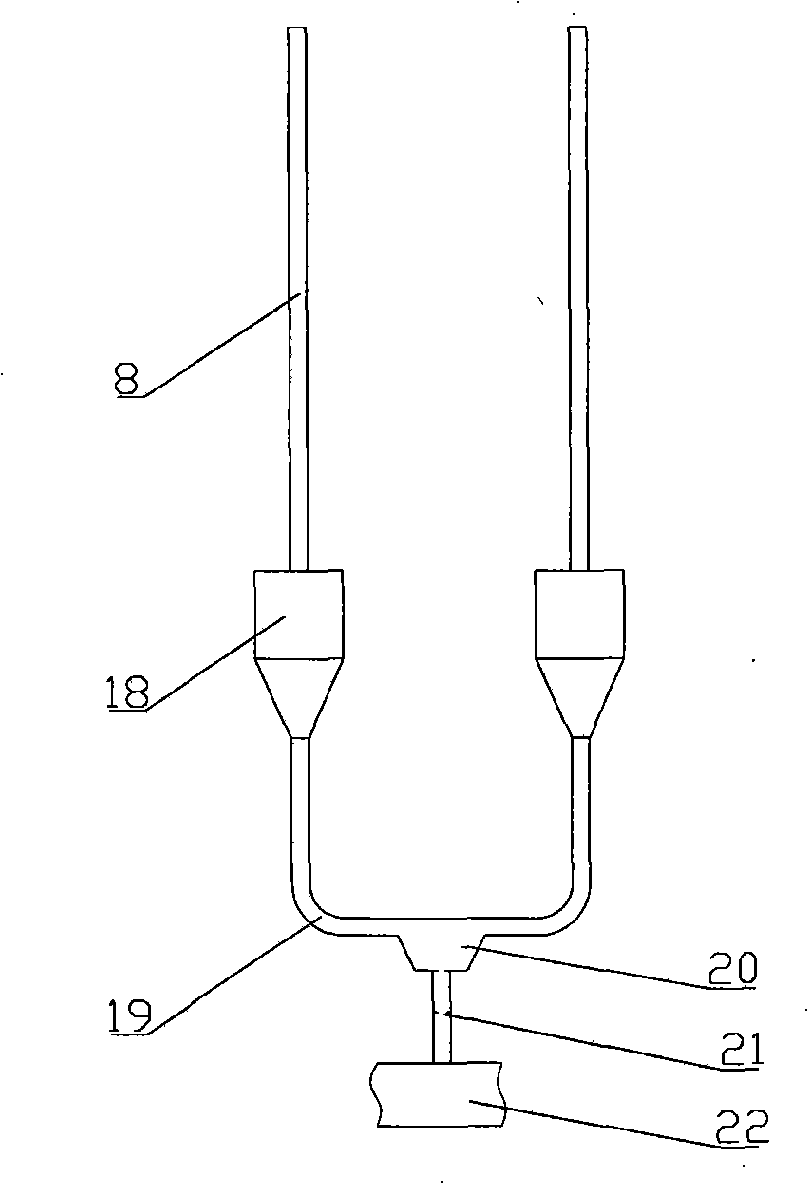

[0019] The damping hedging gas wave refrigerator is mainly composed of the body 2, the upper and lower bearing seats 9, 4, the upper and lower rolling bearings 10, 3, the rotating shaft 5, the upper end cover 16, the sealing packing 12, the sealing gland 15, the coupling 13, and the steady speed motor 14 , air inlet pipe 1, air outlet pipe 6, rotary jet distributor 7, oscillating pipe 8 arranged along the circumference of body 2, damping chamber 18, U-shaped return bend pipe 19, dissipation section communication chamber 20 and gas-sealed liquid drainage conduit 21. Two ends of the oscillating tube 8 are connected to the damping and dissipating structure. The damping and dissipating structure is composed of a damping chamber 18, a U-shaped return bend pipe 19, a dissipating section connecting chamber 20 and a gas-sealed liquid drainage conduit 21. The simplest implementation For example, the ends of every two adjacent oscillating tubes 8 communicate with each other through a dam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com