Combine harvester

A technology for combine harvesters and harvesting devices, which is applied in the directions of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of the harvesting device protruding into the ground, poor operability of the combine harvester, and reduced harvesting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the invention shown in the drawings will be described below.

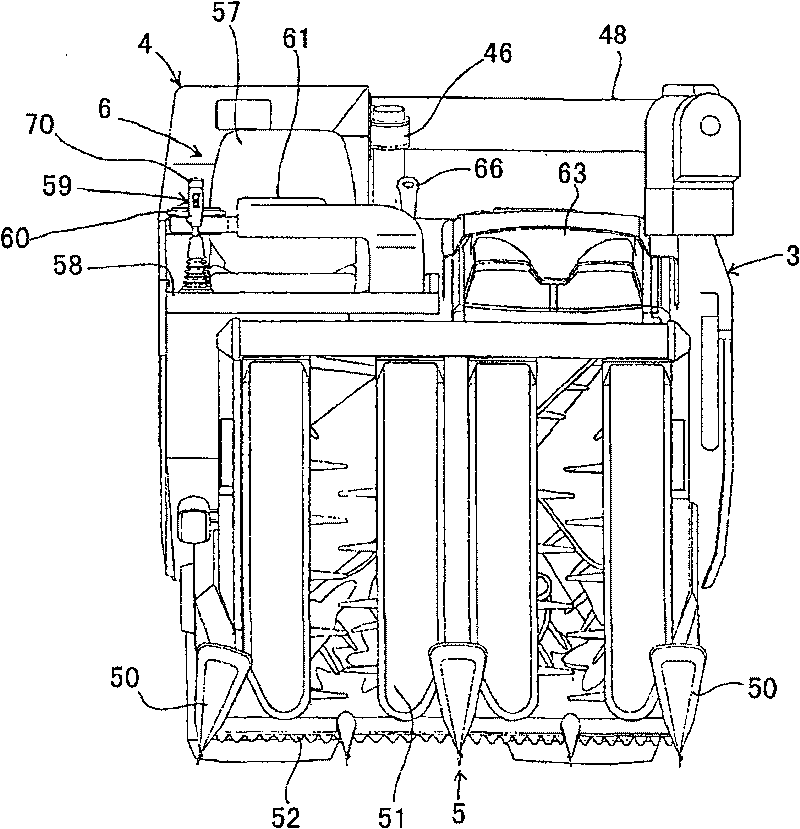

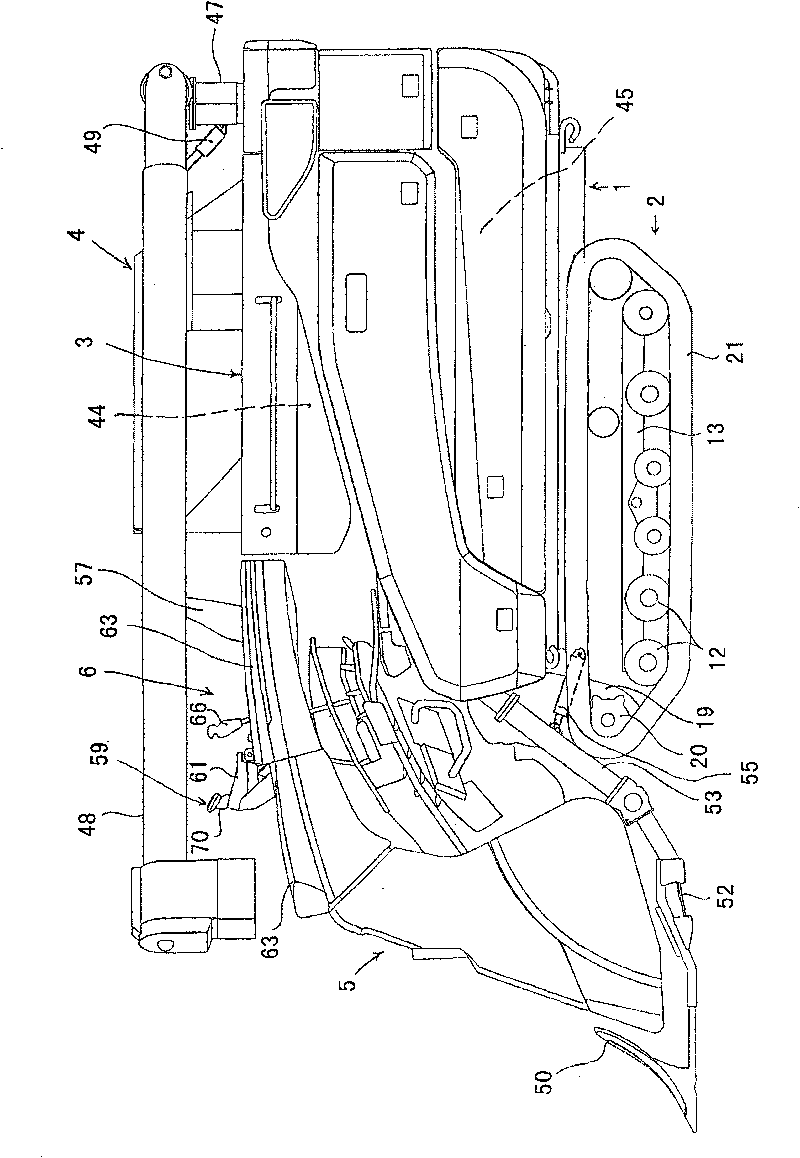

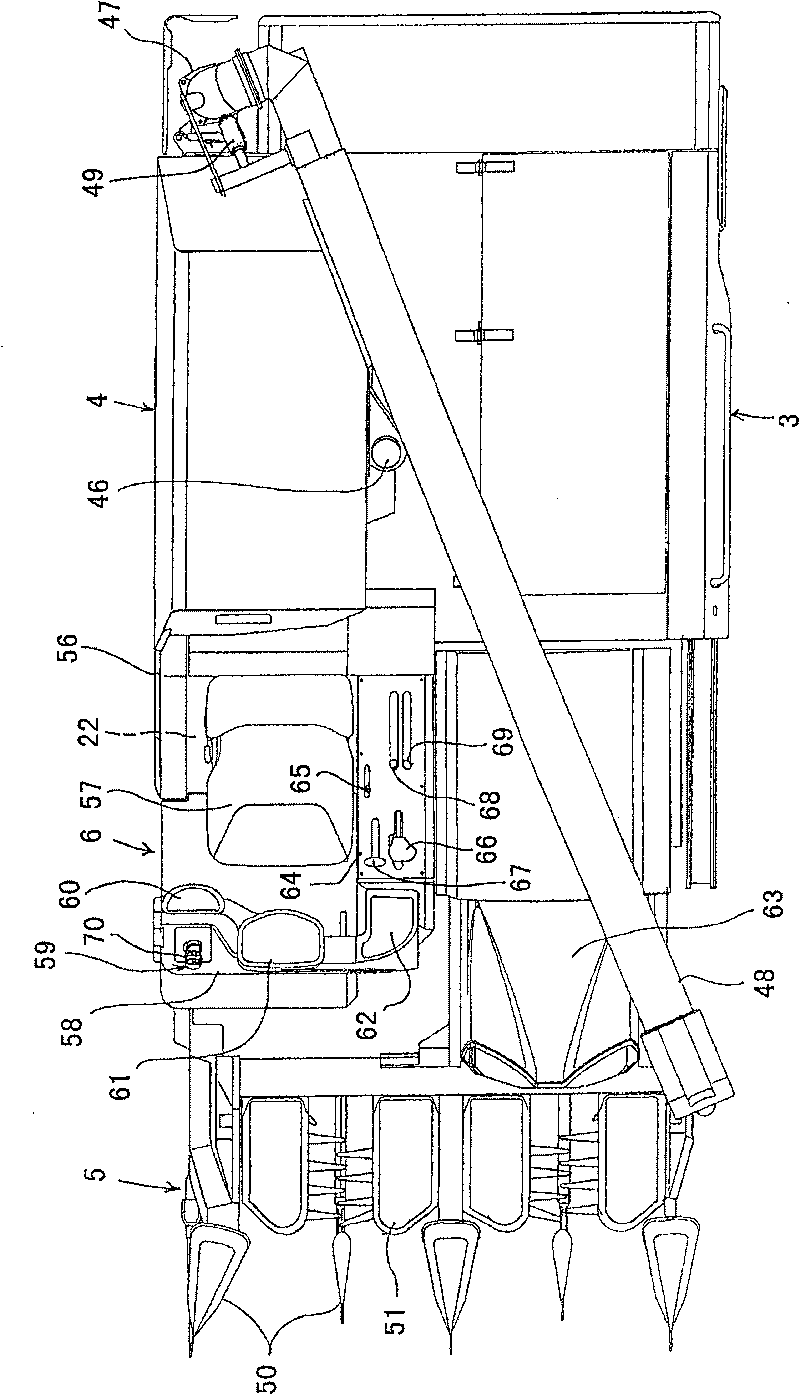

[0030] First, according to figure 1 , figure 2 , image 3 The overall structure of the combine equipped with the control lever of this invention is demonstrated. figure 1 is the front view of the combine harvester, figure 2 is the side view of the combine harvester, image 3 It is a top view of the combine harvester.

[0031] The combine harvesting mechanism is such that a traveling device 2 is provided on the lower side of the vehicle body 1, a threshing device 3 and a grain storage device 4 are arranged side by side on the upper side of the vehicle body 1, and a reaping device 3 is freely installed in front of the threshing device 3. The device 5 is provided with an operation part 6 on the front side of the grain accumulating device 4 .

[0032] Figure 4 , Figure 5 The structure of the above-mentioned traveling device 2 is shown.

[0033] The middle portions of the front swing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com