High-throughput reaction system and method

A reaction system and high-throughput technology, applied in the field of reaction systems, can solve the problems of ineffective use of valuable raw materials, lack of technology for sample injection and online detection, etc., and achieve the effects of saving reaction materials, reducing time, and improving reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

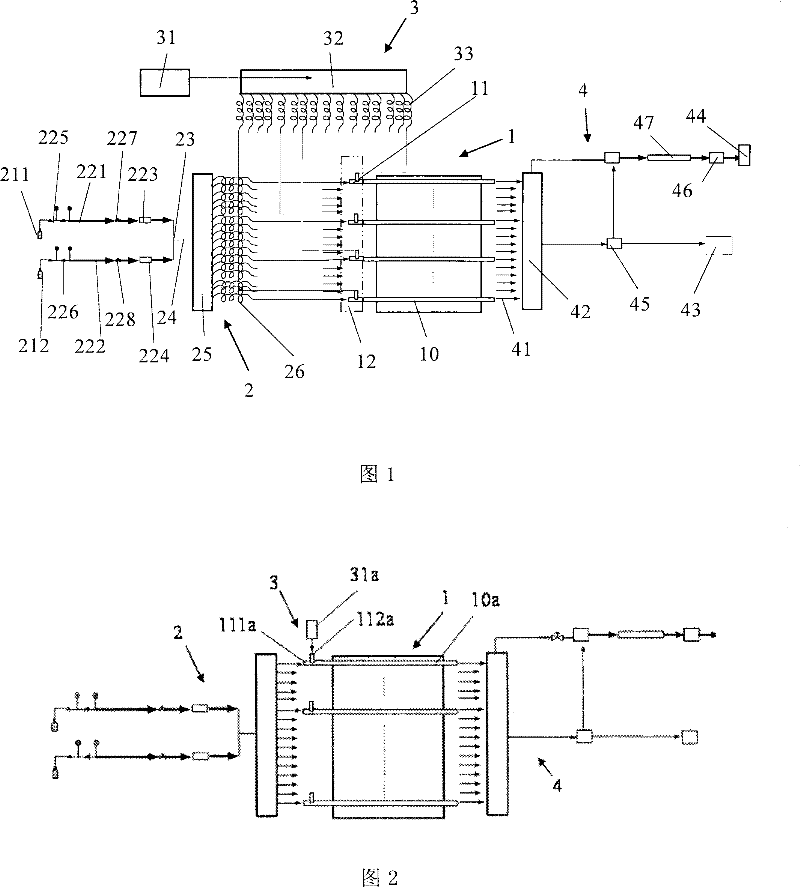

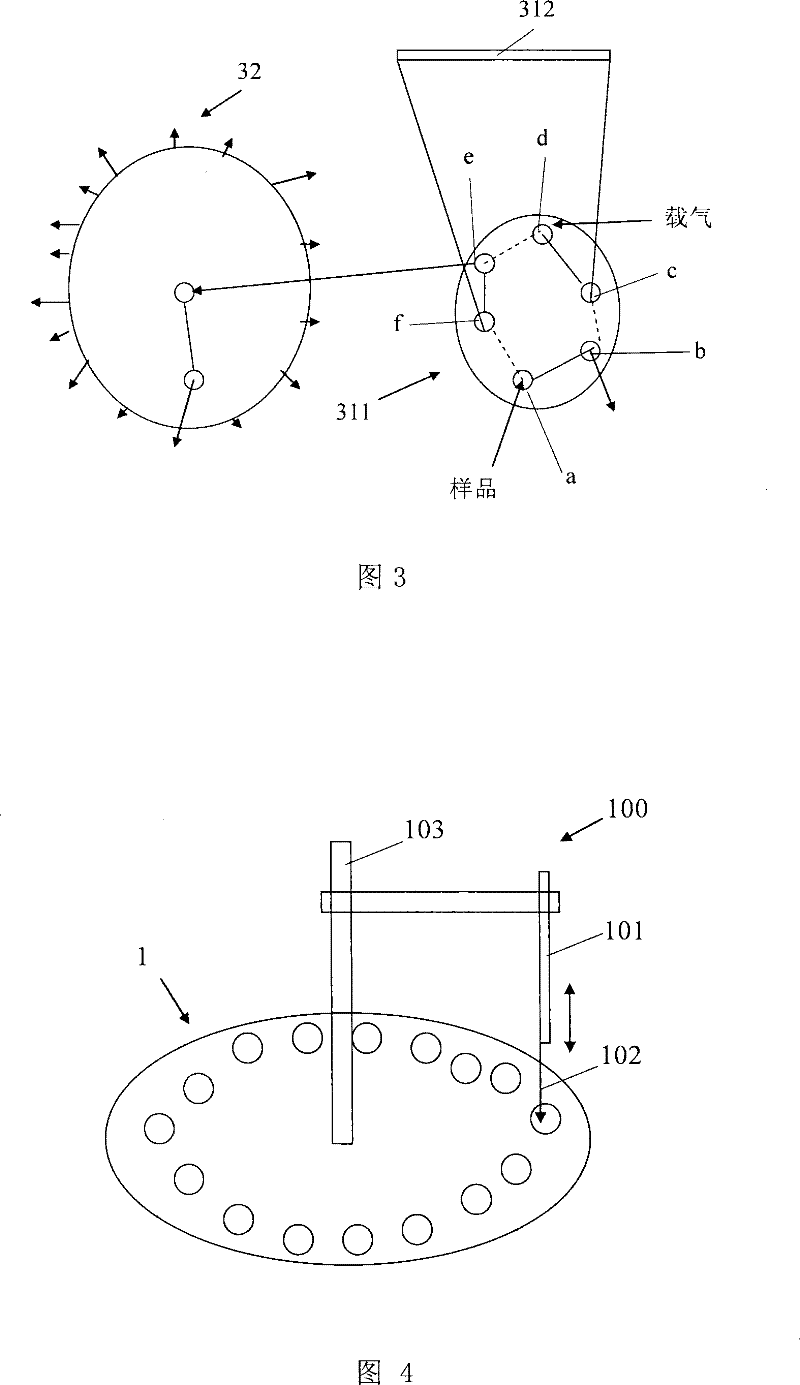

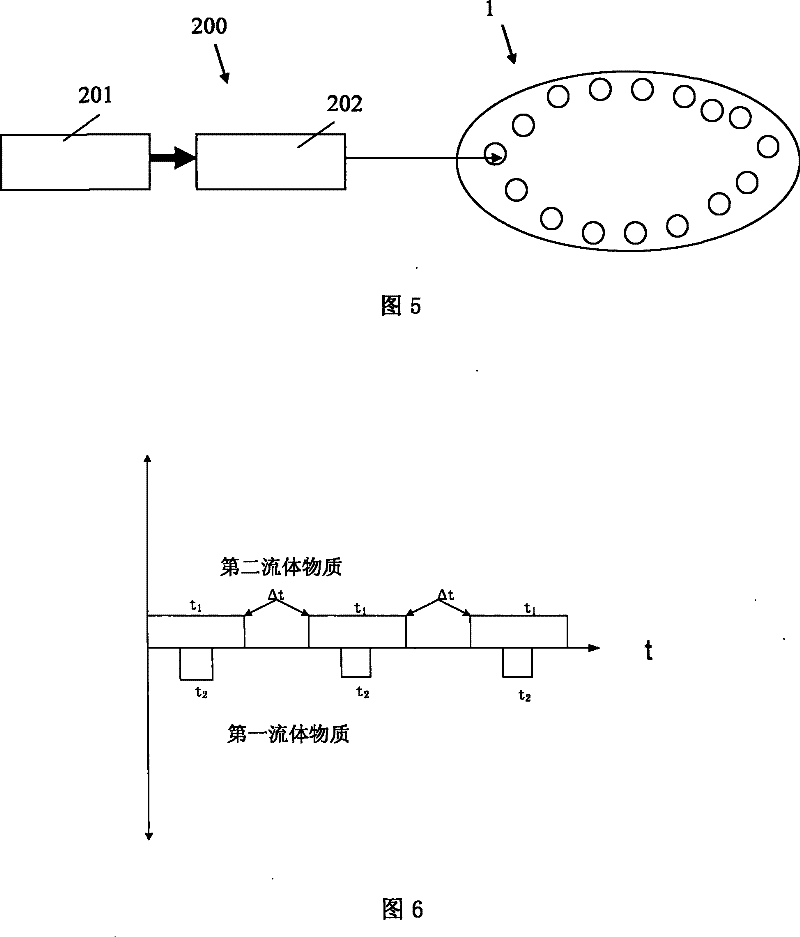

[0018] figure 1 Shown is a schematic diagram of an embodiment of the high-throughput reaction system of the present invention. The high-throughput reaction system of this embodiment includes: a reaction unit 1 that can accommodate a plurality of reaction tubes 10 for reaction, and can be used to continuously process each reaction tube 10. The first sampling unit 2 that provides the first fluid substance, the second sampling unit 3 that can be used to selectively provide the second fluid substance to one or more reaction tubes 10 in a pulsed manner, and the second sampling unit 3 that can be used to selectively from one or more reaction tubes 10 A plurality of reaction tubes 10 collect reaction products online and a sampling and detection unit 4 for detecting the collected products. Therefore, the reaction system of this embodiment is a mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com