Self-adapting high speed sorting mechanism

A self-adaptive and chain technology, applied in sorting and other directions, can solve the problems of not being able to fully adapt to high-speed automatic grading, and achieve the effects of simple structure, improved productivity, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

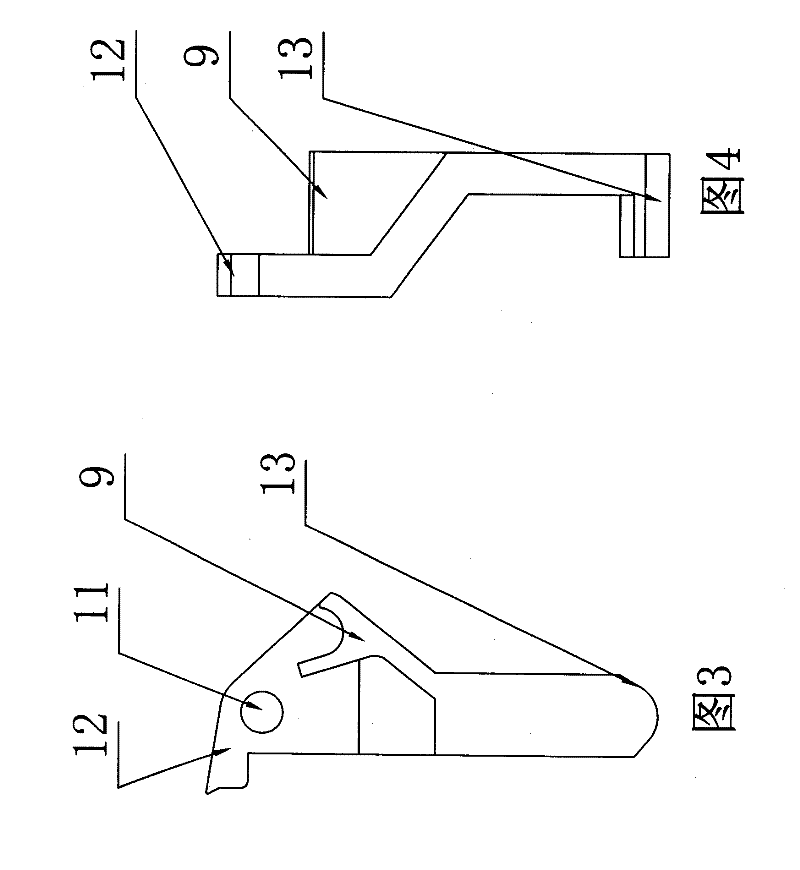

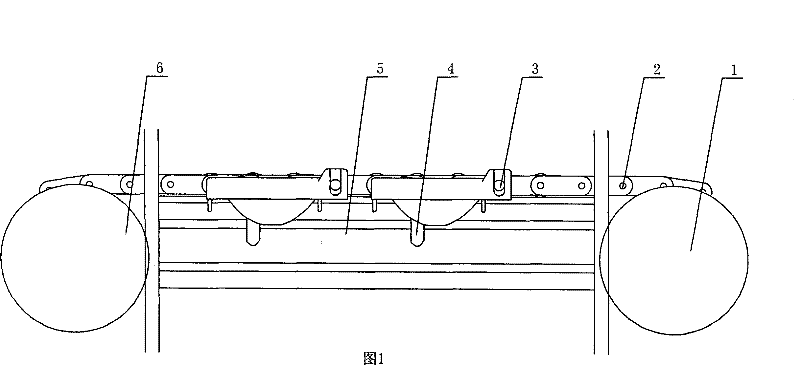

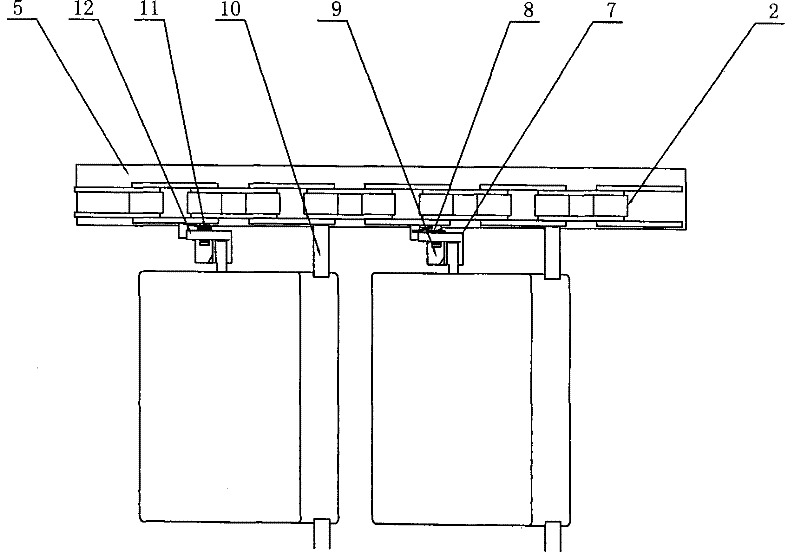

[0019] The reference numbers in the drawings are: 1. Driving sprocket; 2. Graded chain; 3. Fruit cup assembly; 4. Fork assembly; 5. Special aluminum alloy guide rail; 6. Driven sprocket; 7. Fork; 8. 9. Torsion spring; 9. "Y" type boss; 10. Fruit cup connecting pin; 11. Pin mounting hole; 12. Slightly pointed limit; 13. Ramp; 14. Chain outer chain plate; 15 , Gear pin; 16. Install the long pin of the shift fork assembly; 17. Install the long pin of the fruit cup assembly.

[0020] The present invention will be described in detail below in conjunction with the drawings:

[0021] Such as figure 1 As shown, the present invention is composed of a grading chain 2, a shift fork assembly 4 and a fruit cup assembly 3.

[0022] Such as figure 1 , figure 2 , Figure 7 As shown, an adaptive high-speed grading mechanism includes a grading chain. The grading chain includes a driving sprocket 1, a driven sprocket 6 and a grading chain 2, wherein the grading chain 2 is provided on the driving spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com