Helical reinforcement wheel welding and forming equipment and forming method thereof

A technology of spiral steel bar and rotating device, applied in welding power source, welding equipment, resistance welding equipment and other directions, can solve the problems of inefficient, multi-manpower and time, consumption and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

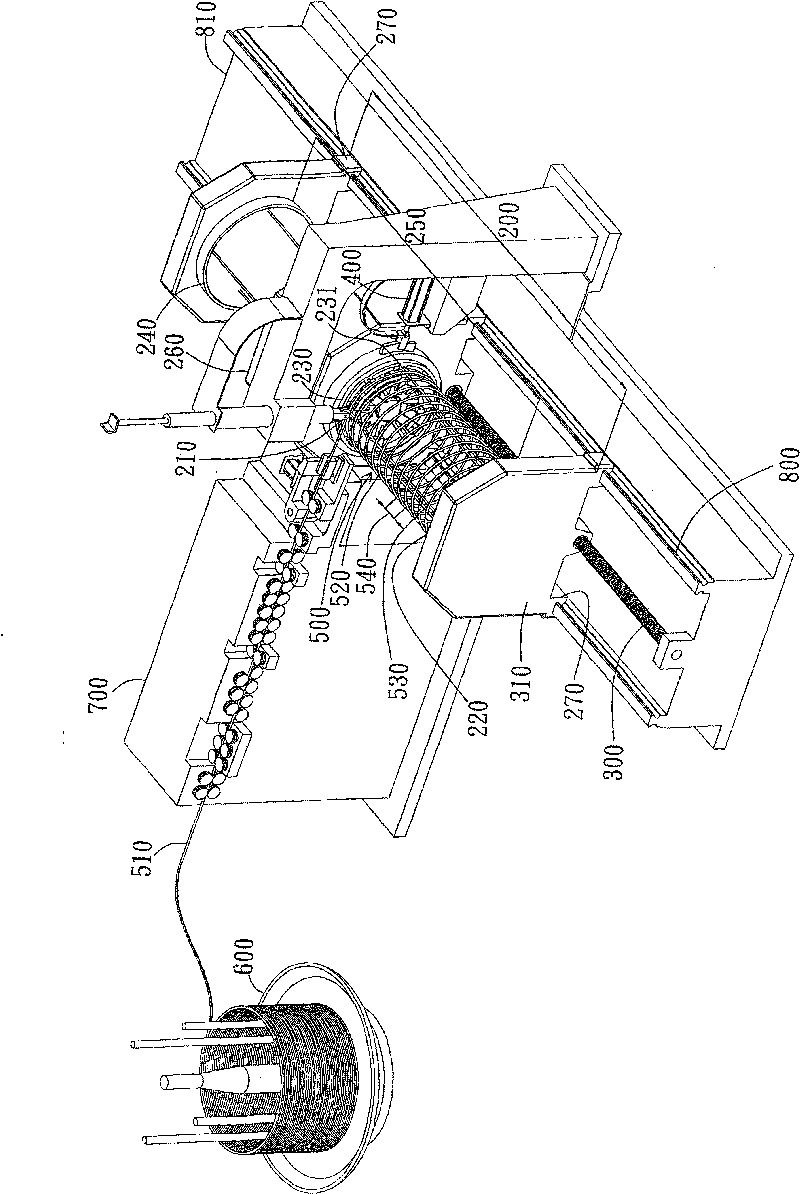

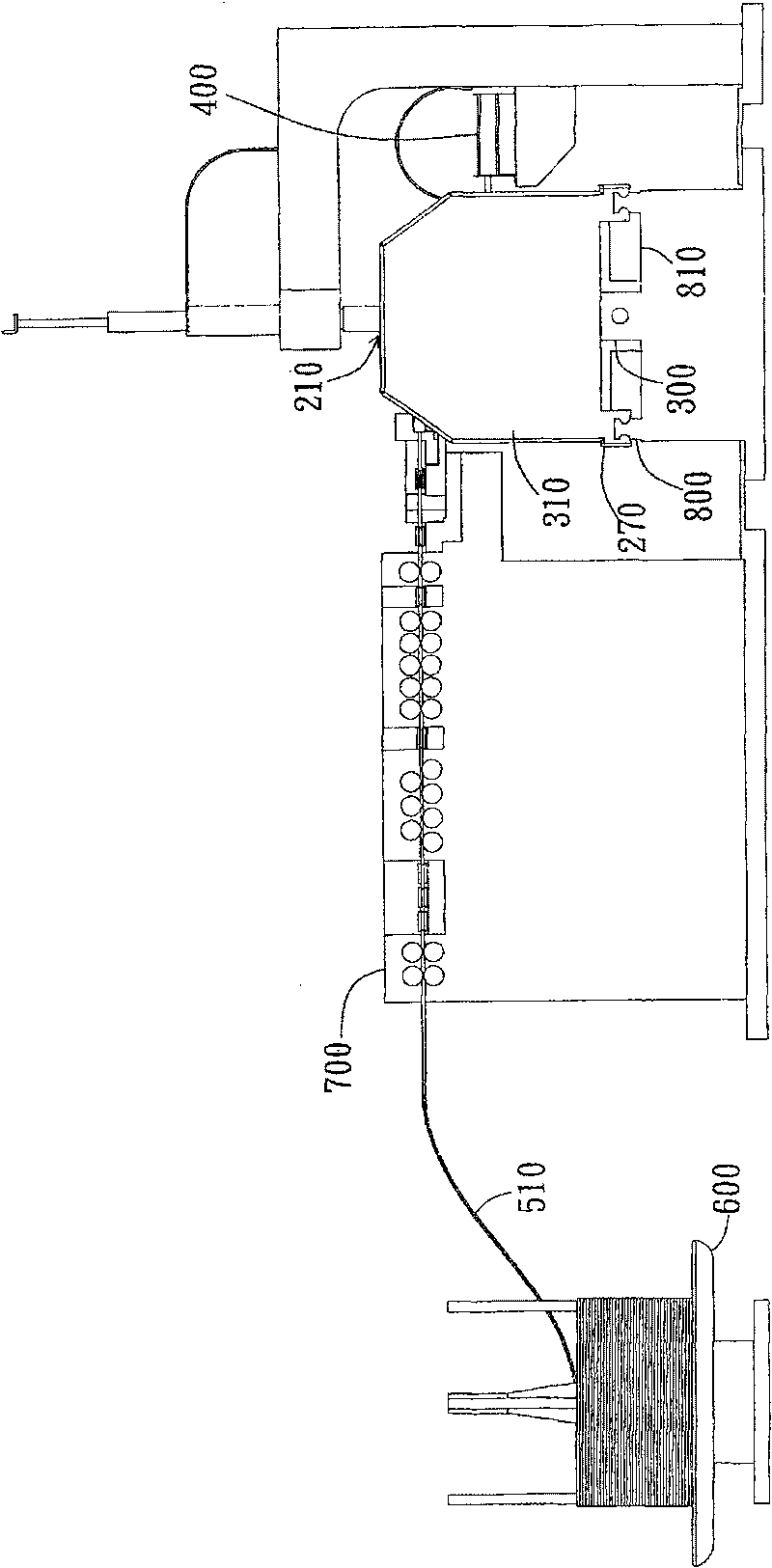

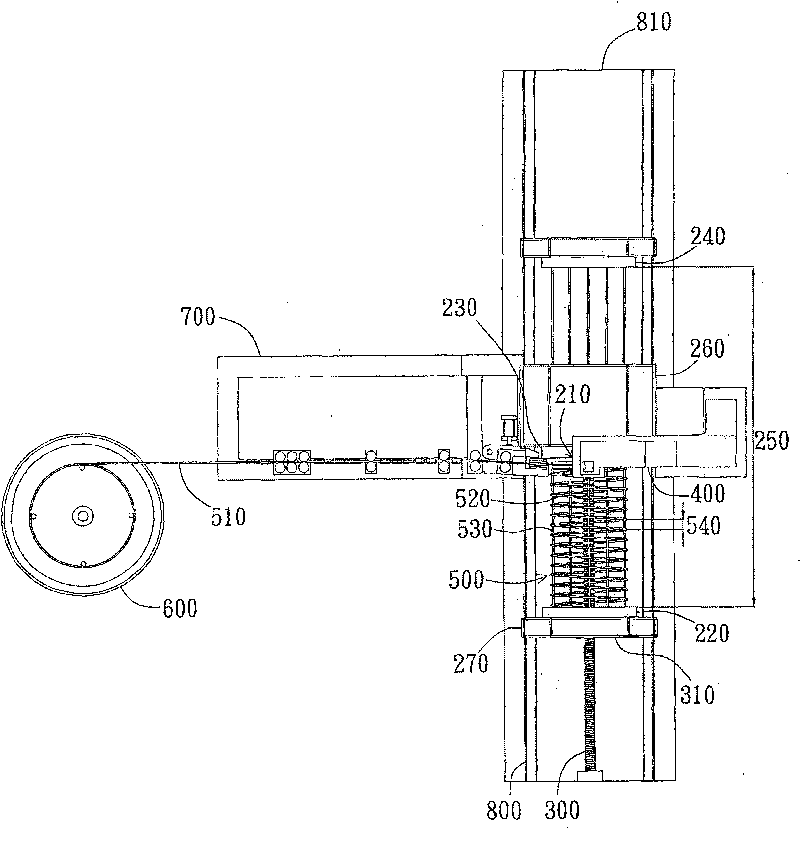

[0058] The invention provides a spiral steel bar wheel welding forming device for efficiently forming a spiral steel bar cage. The spiral steel bar wheel welding forming device of the present invention is preferably used to replace the previous construction method of manually binding spot bars and spiral steel bars with iron wires or spot welding. The spiral steel cage formed by the spiral steel bar wheel welding forming device of the present invention is preferably used for reinforced concrete cylinders in construction industry, construction industry, traffic road engineering, aquatic product engineering and the like. However, in different embodiments, the shaped helical reinforcement cage can also be used as a stirrup structure of a building or other structural units of a building.

[0059] Such as figure 1 As shown, the spiral steel bar wheel welding forming device of the present invention is preferably used to form a spiral steel bar cage 500 with a plurality of pitches 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com