Temperature-resistant water-soluble copolymer, preparation and use thereof

A technology of water-soluble copolymers and hydrophobic monomers, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of loss of hydrophobic association function, disappearance of temperature thickening effect, limited temperature resistance, etc., to achieve High viscosity-increasing ability, not easy to curl, strong rigid effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

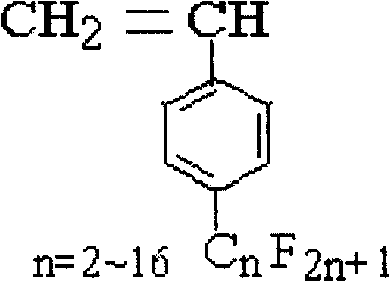

Method used

Image

Examples

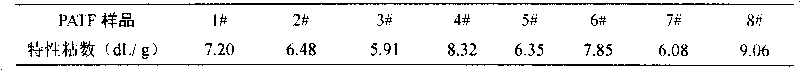

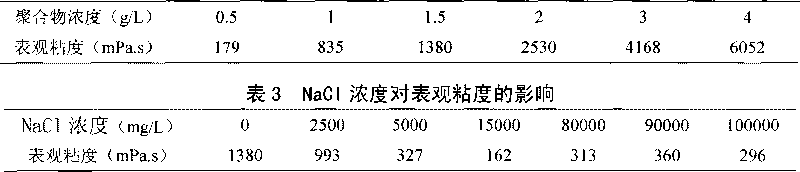

Embodiment 1

[0034] Dissolve 20.000 grams of acrylamide, 9.062 grams of acrylic acid, 2.350 grams of 2,3,4,5,6-pentafluorostyrene and 53.200 grams of sodium lauryl sulfate in 569 ml of distilled water, add them to a three-necked reaction flask, and adjust with NaOH Solution pH=8, reaction temperature 35°C, pass N 2 After 30 minutes, add 1.82 mL of 0.05 mol / L potassium persulfate initiator solution, react for 16 hours, and dilute the polymer with water to obtain a PATF concentrated solution.

Embodiment 2

[0036] Dissolve 20.000 grams of acrylamide, 0.650 grams of 2-acrylamido-2-methylpropanesulfonic acid, 0.930 grams of 3,5-bis(trifluoromethyl)styrene and 4.120 grams of sodium lauryl sulfate in 66 ml Deionized water, adjust pH=4 with NaOH, reaction temperature 50°C, pass N 2 After 30 minutes, add 1.08 mL of 0.05 mol / L ammonium persulfate initiator solution and react for 10 hours. The polymer was dissolved in water to prepare a concentrated solution of PATF.

Embodiment 3

[0038] Dissolve 20.000 grams of acrylamide, 6.400 grams of dimethyl diallyl ammonium chloride, 0.420 grams of 4-perfluoroethyl styrene and 3.800 grams of trimethylhexadecyl ammonium bromide in 180 ml of deionized water, Use hydrochloric acid to adjust the pH=7.5, the reaction temperature is 40°C, pass N 2 After 30 minutes, add 1.250 mL of 0.05 mol / L potassium persulfate initiator solution and react for 24 hours. The polymer was dissolved in water to prepare a concentrated solution of PATF.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com