Discontinuous centrifugal machine which is intended, in particular, to separate molasses from sugar crystals in a masse-cuite

A centrifuge, intermittent technology, applied in sugar crystal separation, centrifuge, sugar production, etc., can solve problems such as uneven stress distribution and premature wear of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

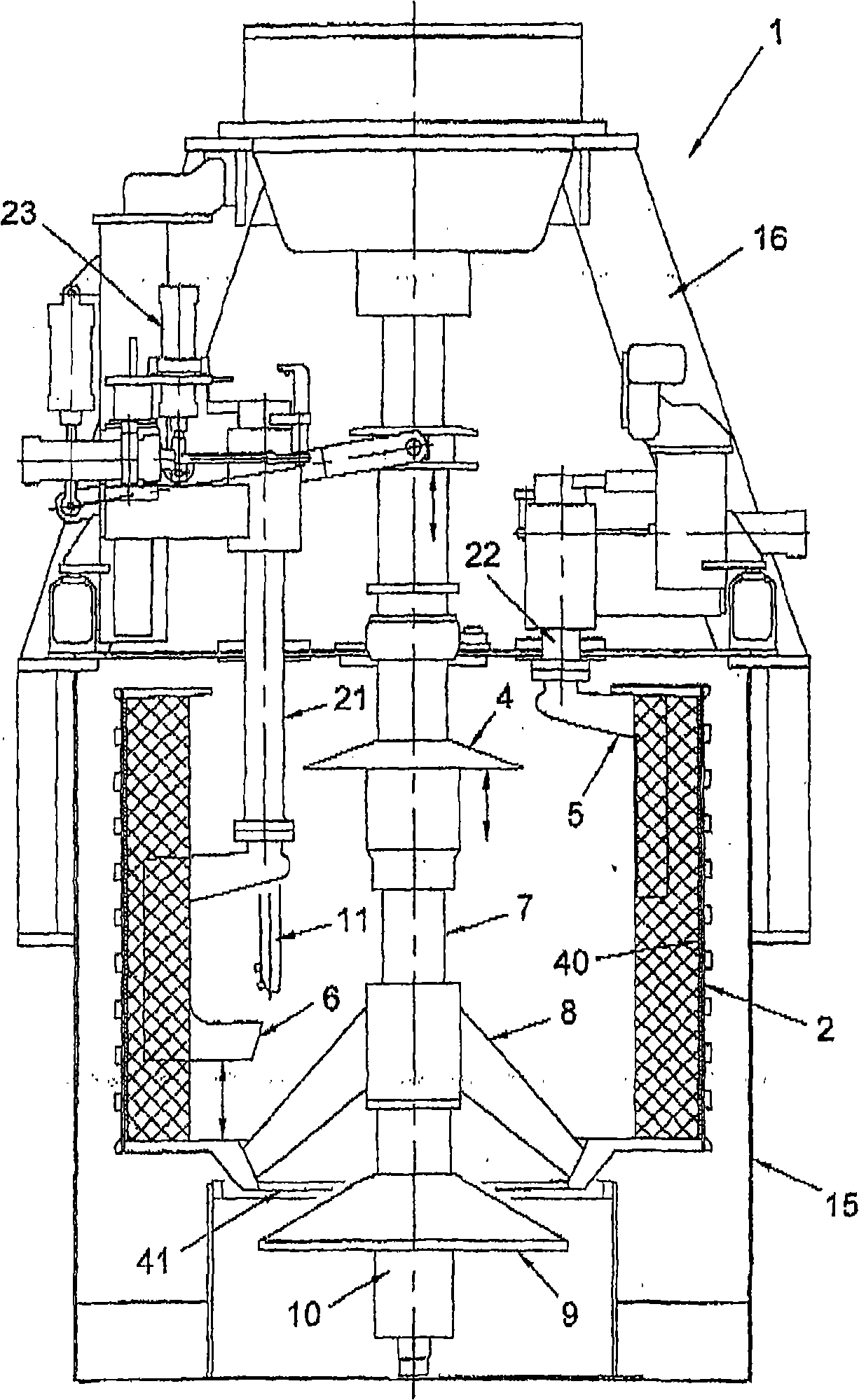

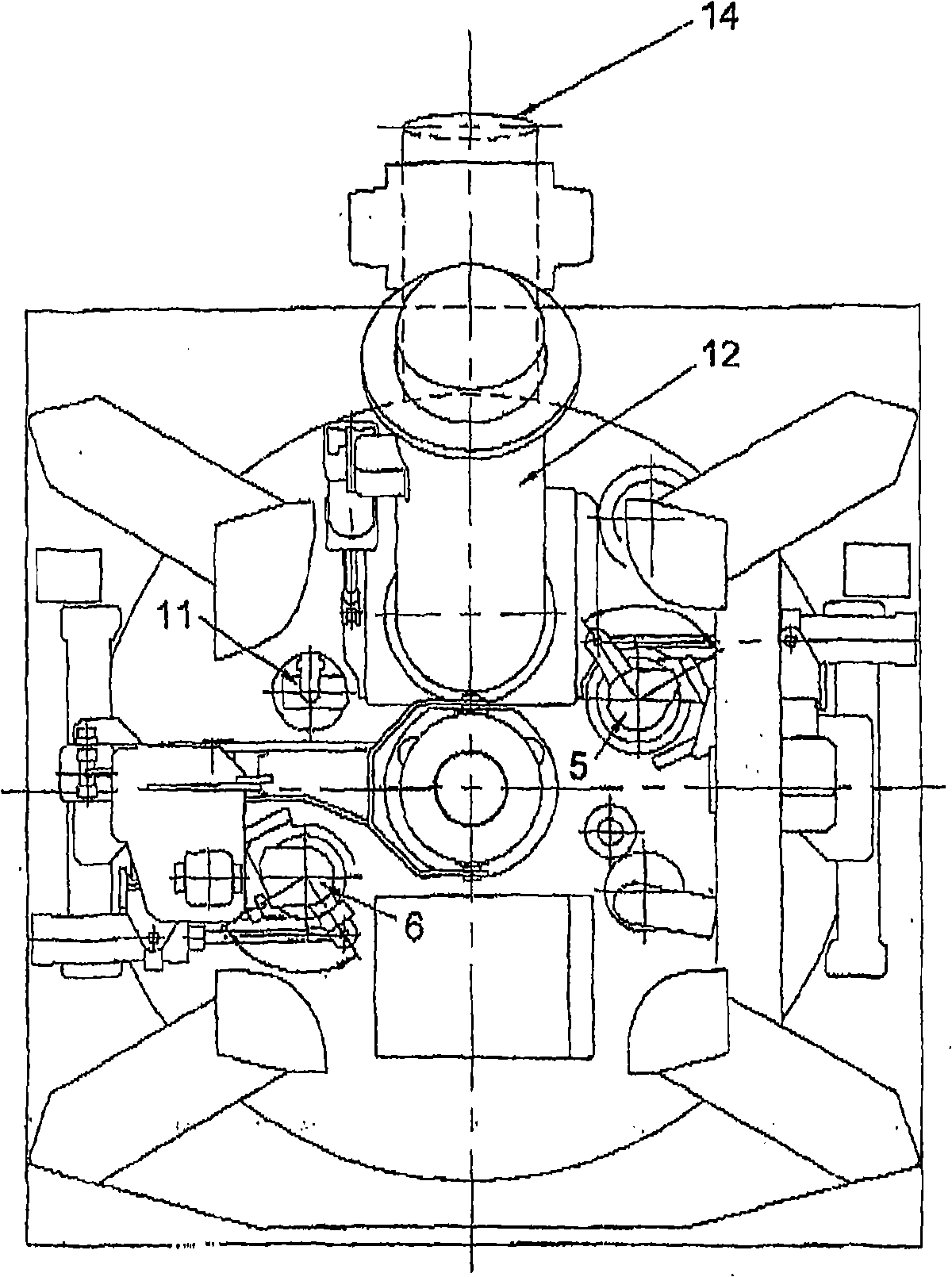

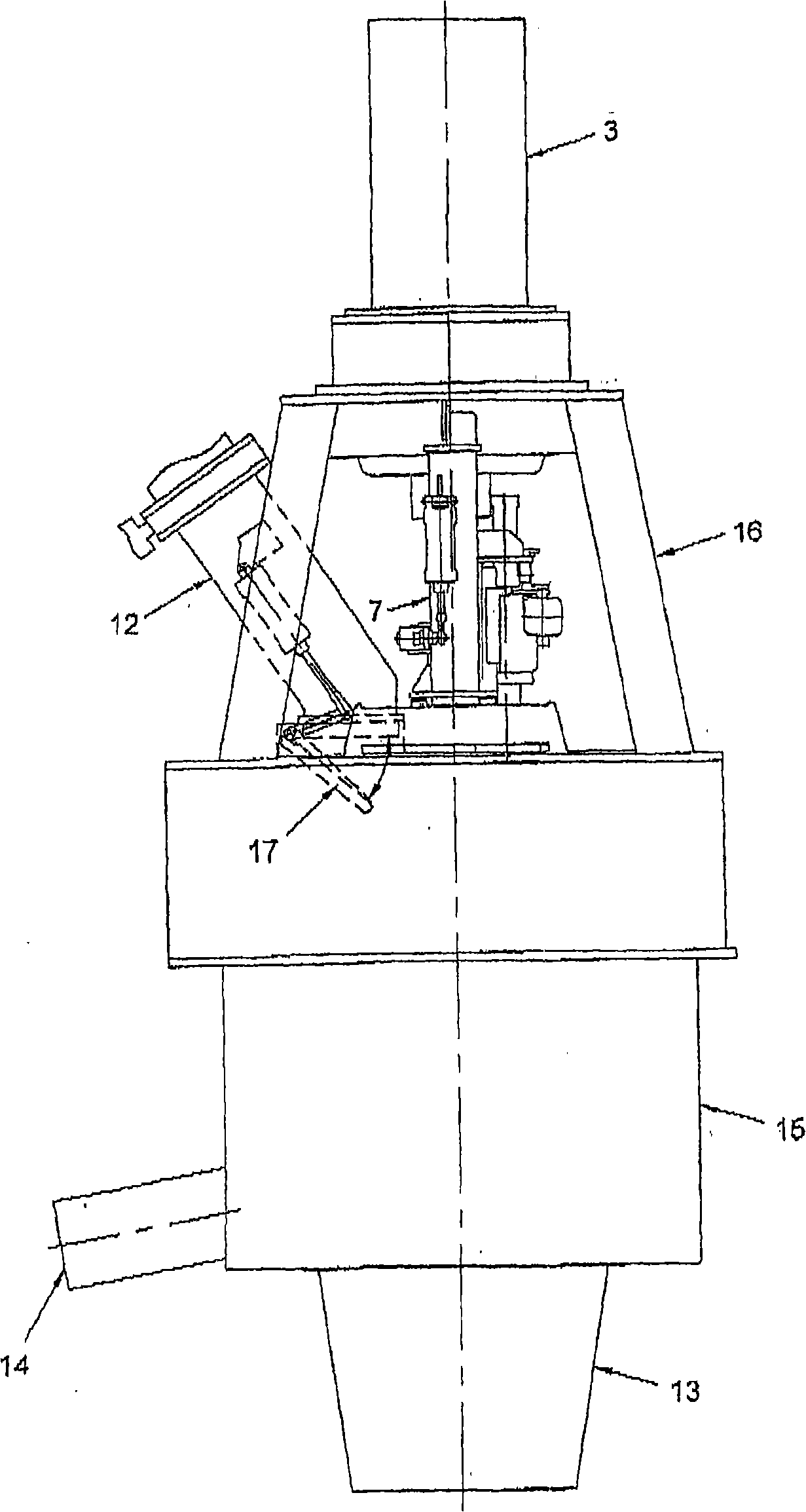

[0026] The invention relates firstly to a batch centrifuge 1 , in particular to a centrifuge for separating molasses from sugar crystals in massecuite.

[0027] The centrifuge includes at least the following elements:

[0028] - a centrifugal drum 2 for containing the product to be treated and having a permeable wall 40,

[0029] - a plurality of motor means 3 for driving the drum 2 in rotation around a vertical axis of rotation,

[0030] - An unloading device comprising means for scraping the permeable inner wall 40 of the drum.

[0031] According to the invention, said means for scraping the wall 40 consist of a set of at least two scoops 5, 6 distributed inside the drum and articulated in rotation about at least one vertical axis.

[0032] Such as figure 1 As shown, according to one embodiment, the drum 2 is housed in a vertically arranged cuve 15 , supported in particular by a coaxial axis of rotation 7 . The motor arrangements 3 , in particular electrical arrangements...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com