Optical disk drive and tracking error detection method for an optical disk drive

A technology of optical disc drive and tracking error, which is applied in the direction of recording/reproducing with optical methods, instruments, optical record carriers, etc., and can solve the problems of inapplicability, unreliable signal, disappearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

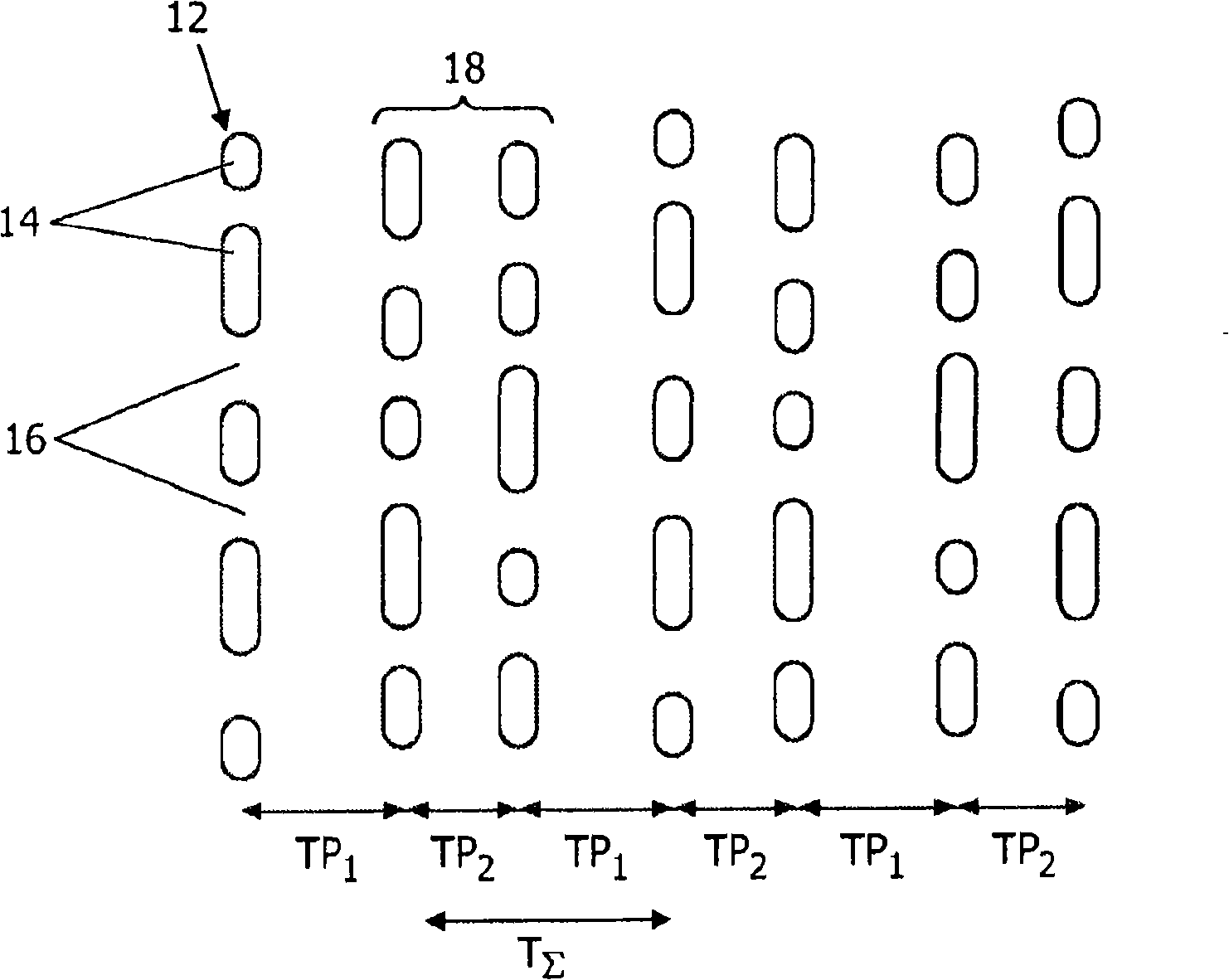

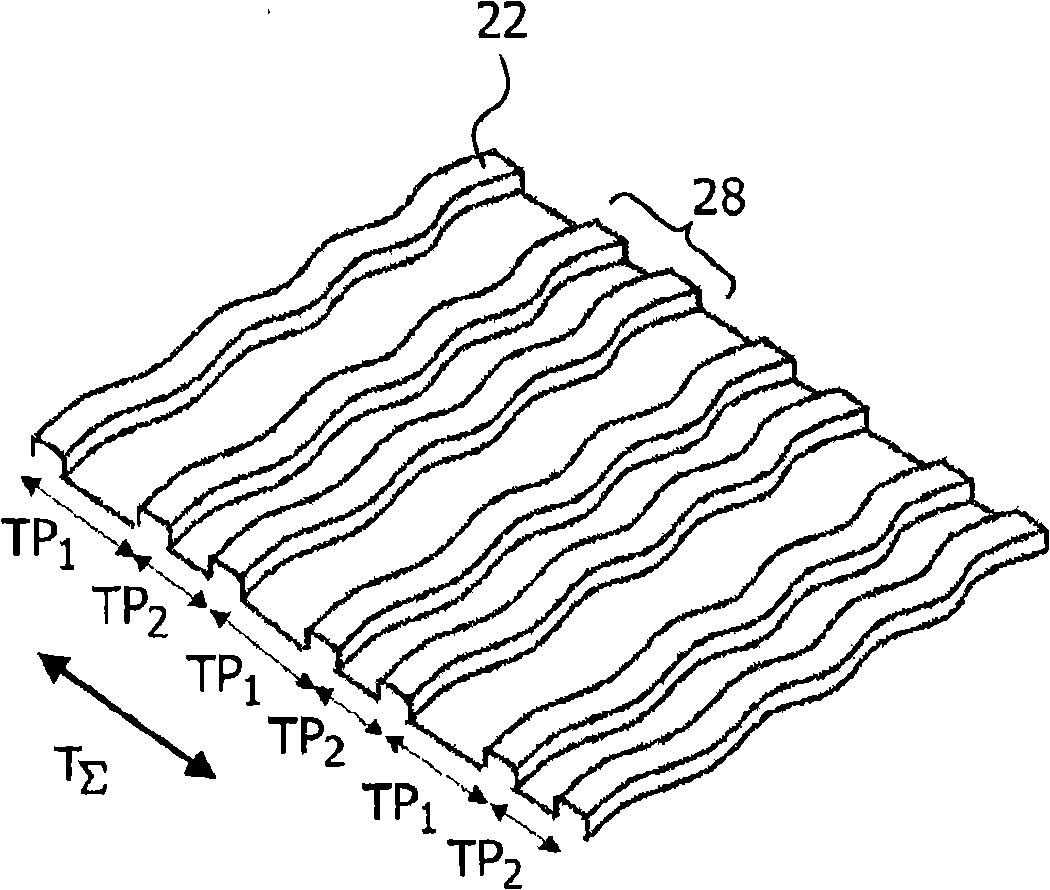

[0033] figure 1 The portion of the new disk shown represents the disk in read-only format. A track portion 12 therein is constituted by trajectories formed by pits 14 and lands 16 . likewise in figure 2 , a perspective view of a portion 20 of a (re)writable disc is shown, where the track portion is formed by a wobbled pre-groove 22 . Such pre-grooves for tracking purposes in non-written optical discs are known, for example, from the CD-R / RW, DVD±R / RW or BD-R / RF standards, among others.

[0034] On both formats, tangential tracks of pits and lands in the read-only format and pre-grooves in the (re)writable format, the track portions 12, 22 are not equally spaced. Select two different track pitches TP 1 and TP 2 , so that every second track portion is set to the left from its adjacent track portion by the first distance TP 1 and a second distance TP at the right margin to its adjacent track portion 2 . In this way, beams 18 and 28 are formed, respectively, consisting of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap