Technique for producing arcuated combined flue pipe

A production process and air duct technology, which is applied in the field of the production process of arc-shaped combined air ducts, can solve the problems of affecting the ventilation effect, inconvenient use and installation, air duct airflow obstruction, etc., so as to ensure the cooling and heating effect, and the installation is convenient and simple. , to avoid the effect of airflow obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

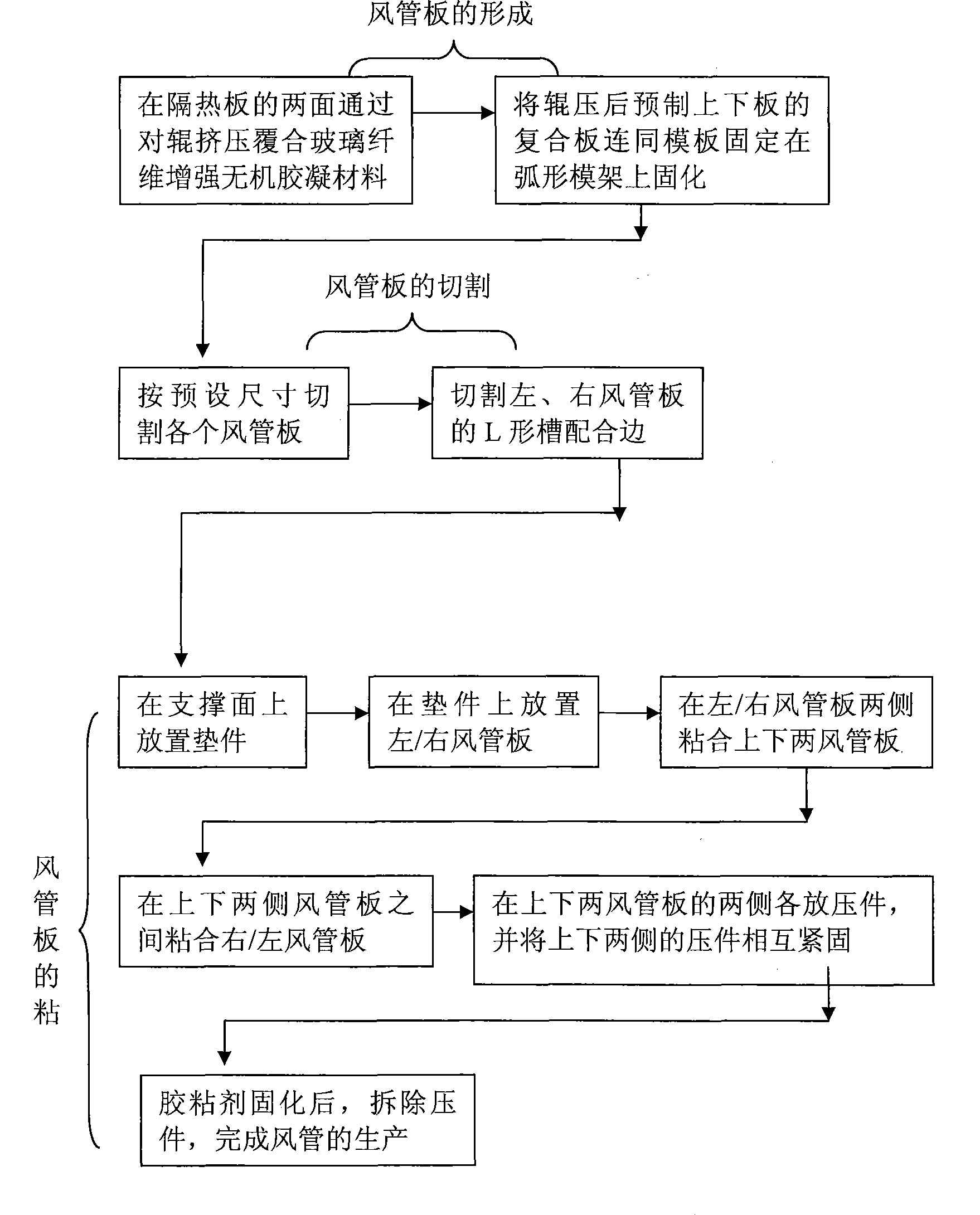

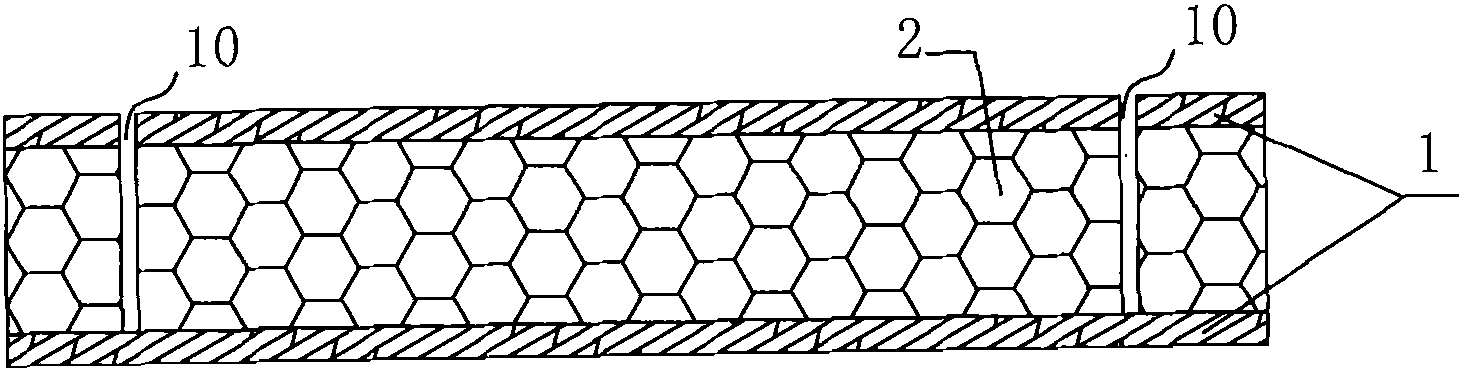

[0021] Embodiment 1: A manufacturing process of a curved combined air duct, such as figure 1 As shown, the steps of the process are: step one, making of the air duct plate; step two, cutting of the air duct plate; step three, bonding of the air duct plate, and the manufacturing process of the air duct plate is: a. Roll one layer of fiber-reinforced inorganic viscose layer 1 on the template, then place the selected heat insulation board 2 on the fiber-reinforced inorganic viscose layer 1, and then roll a layer of fiber-reinforced inorganic viscose on the upper surface of the heat insulation board 2. Adhesive layer 1, forming a composite board (such as image 3 shown); b, the composite boards of the prefabricated left and right air duct panels are placed flat and solidified; c, after the composite panels of the prefabricated upper and lower air duct panels 5 are bent into an arc together with the formwork, they are fixed on the curved concave Solidification and setting on the s...

Embodiment 2

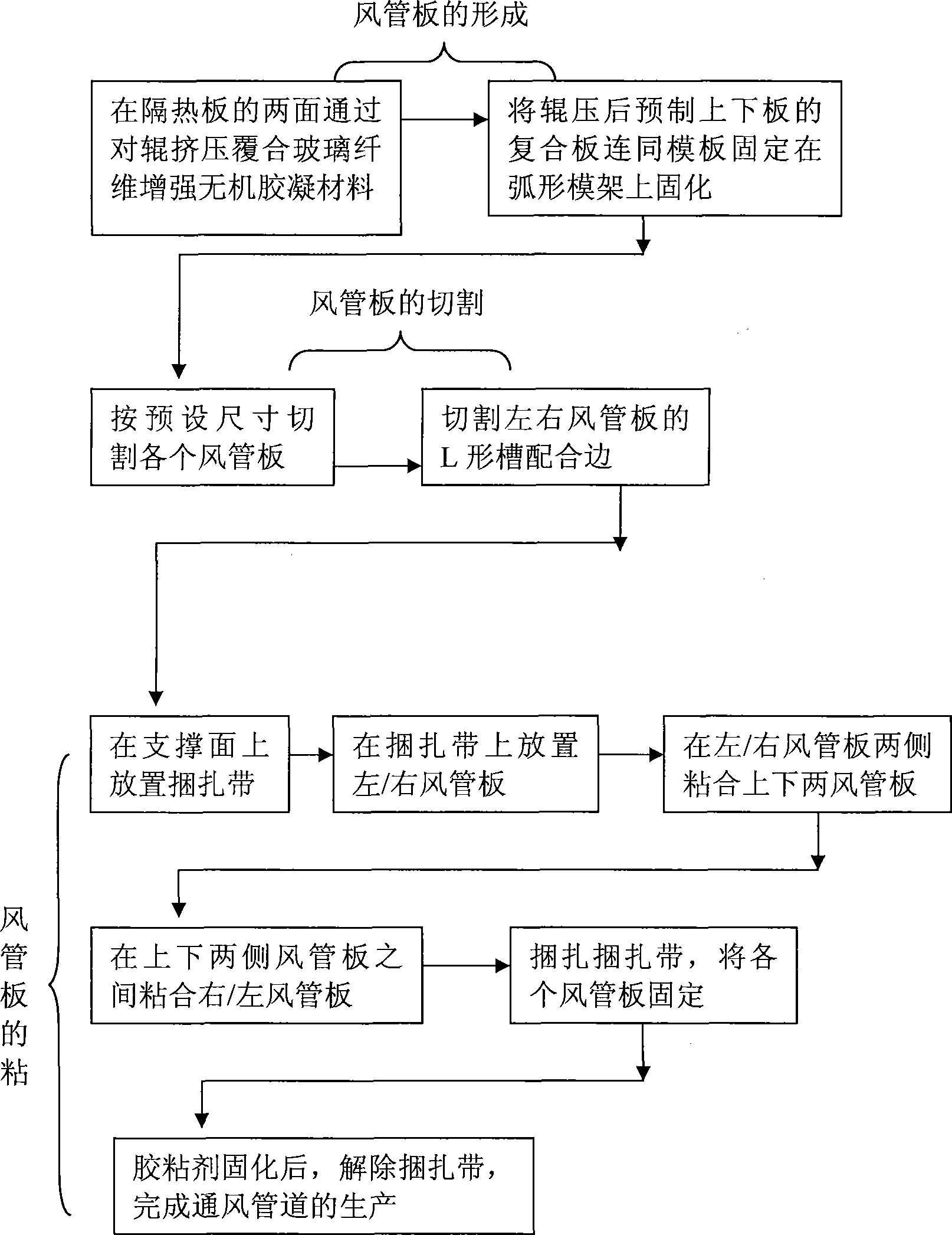

[0024] Embodiment 2: A kind of manufacturing process of curved combined air duct, such as figure 2 and Figure 8 As shown, the bonding process of the air duct plate included in the process is: A, first place a plurality of straps 9 evenly on the bearing surface, and place the left and right air duct plates 4 on the straps 9; B , the upper and lower air duct plates 5 are bonded to both sides of the left and right air duct plates, then the left and right air duct plates 4 are bonded between the two air duct plates; C, the binding strap 9. Bundling along the transverse direction of each air duct plate; D. After the adhesive is cured, remove the above-mentioned binding belt 9. All the other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com