Longitudinal feeding structure of electronic pattern sewing machine

A pattern sewing machine and longitudinal feeding technology, which is applied in the field of sewing machines, can solve problems such as waste of labor and clothing materials, incorrect patterns or patterns, and tilting of the cloth pressing device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

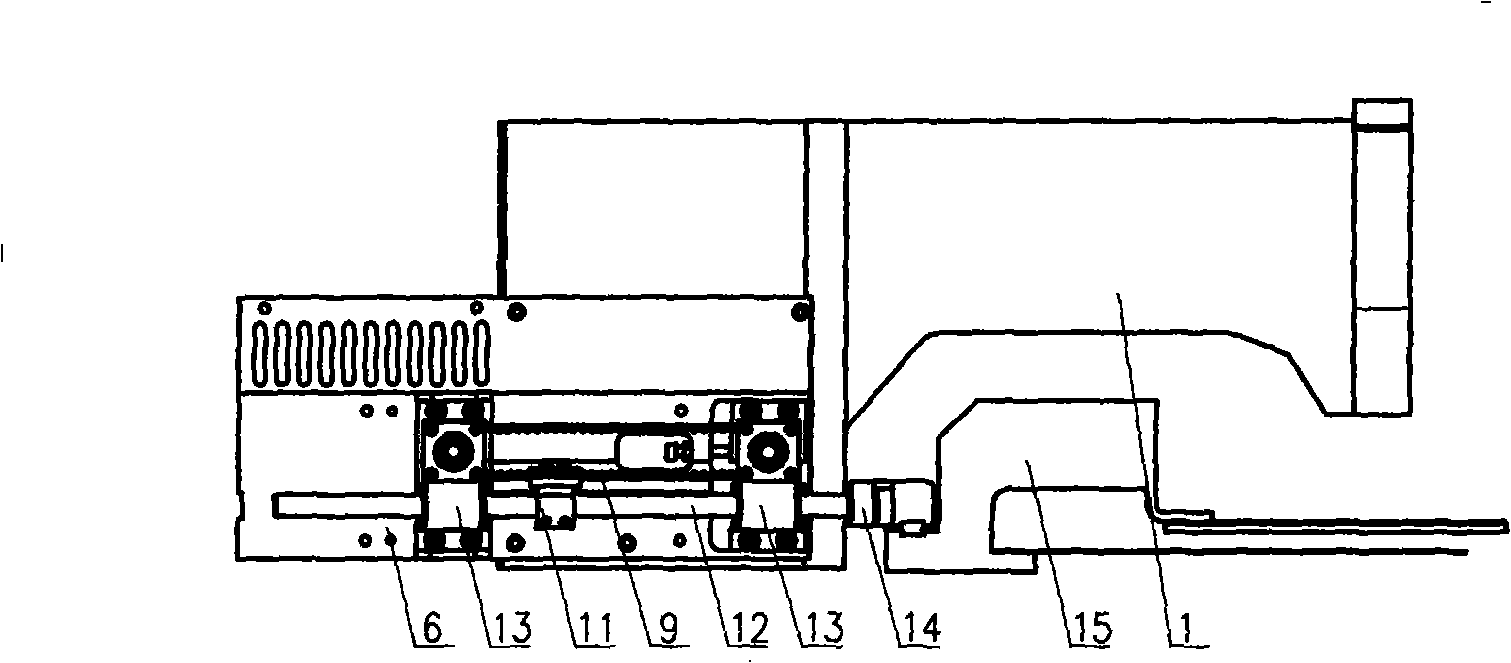

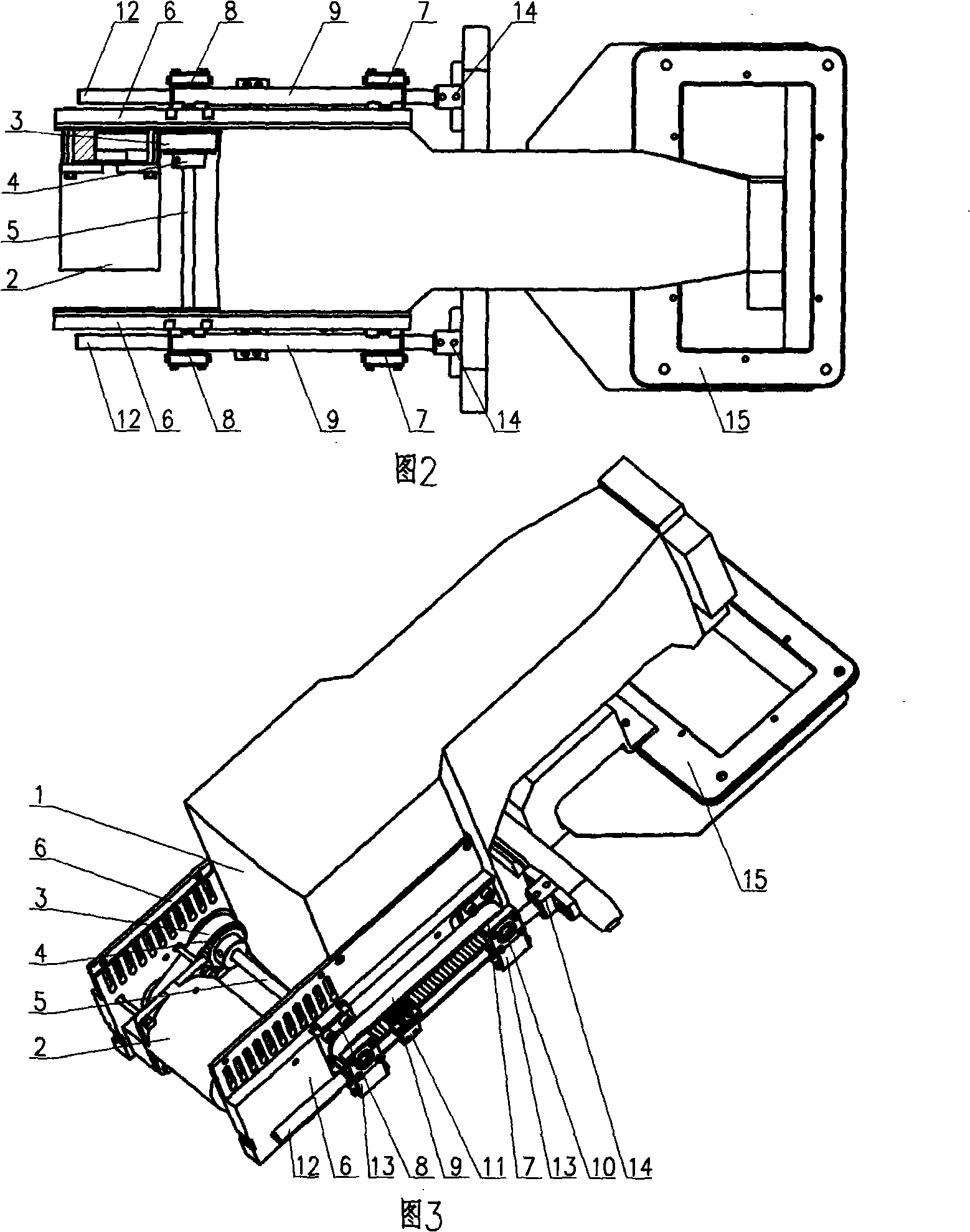

[0009] refer to figure 1 , Fig. 2 and Fig. 3, the cloth pressing device 15 and the feed shaft 12 are connected together through the connection assembly 14, the feed shaft 12 pushes the cloth pressing device 15 to realize longitudinal feeding, and the feed shaft 12 is separately installed in the machine head 1 On the feed shaft holders 13 on both sides, the feed shaft holders 13 are fixed on the fixed bracket 6 with screws respectively. At this time, the fixed bracket 6 is installed on the machine head 1 with screws, and the power of the feed shaft 12 It is provided by the feed synchronous belt 9. At this time, the feed shaft 12 and the feed synchronous belt 9 are connected together by the feed shaft and the synchronous belt clamping assembly 11, and the feed synchronous belt 9 is fed through the active synchronous pulley 7 to drive. The feeding active synchronous pulley 7 is installed at both ends of the synchronous pulley shaft 5, through the synchronous pulley 4 installed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com