Kinetic pressure gas bearing structure with radial support foil slice

A dynamic pressure gas bearing and radial support technology, applied in sliding contact bearings, rotating bearings, bearings, etc., can solve the problems of poor high temperature resistance of elastic rubber sheets, achieve good high temperature resistance, improve reliability and Economical and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

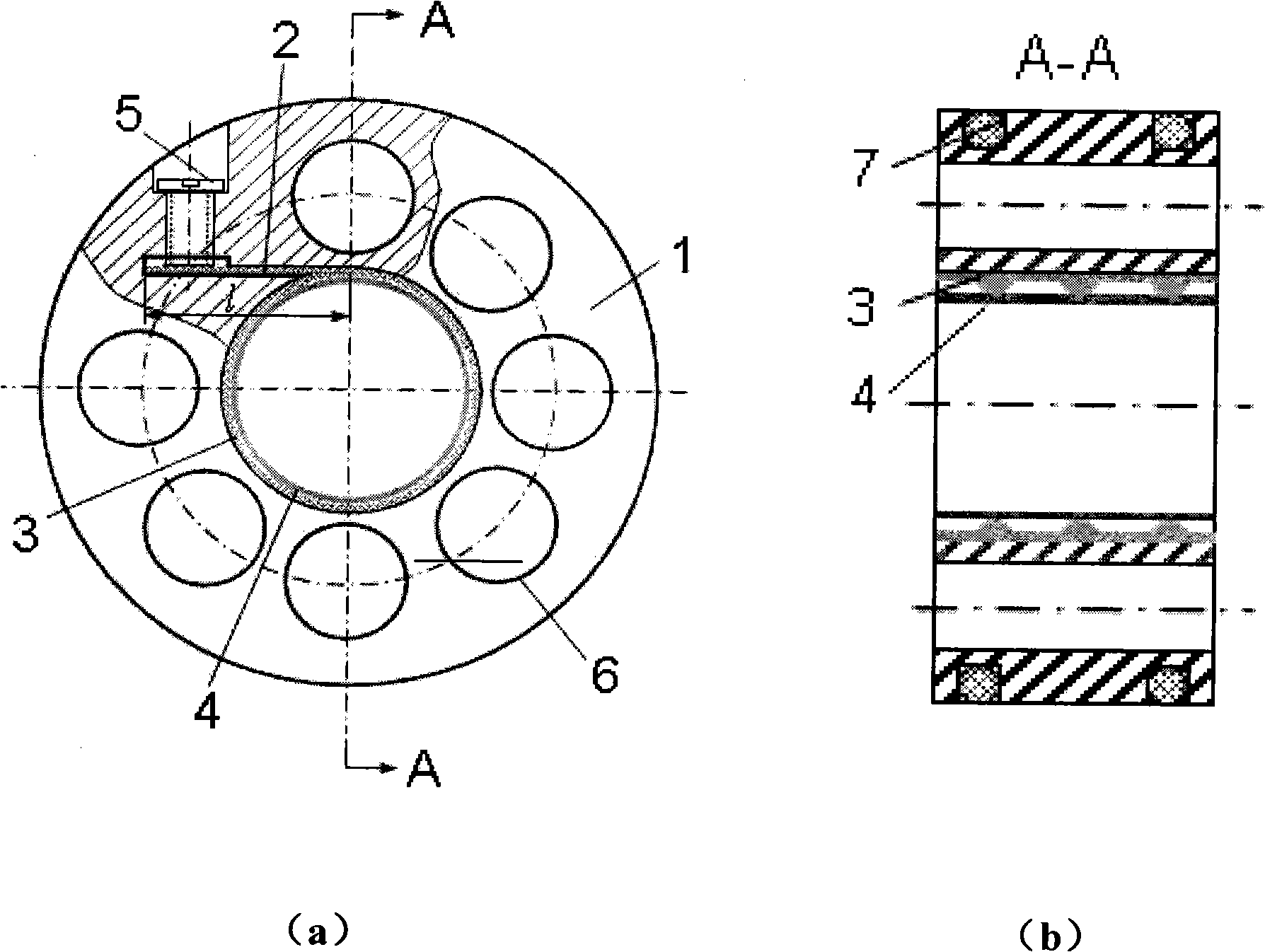

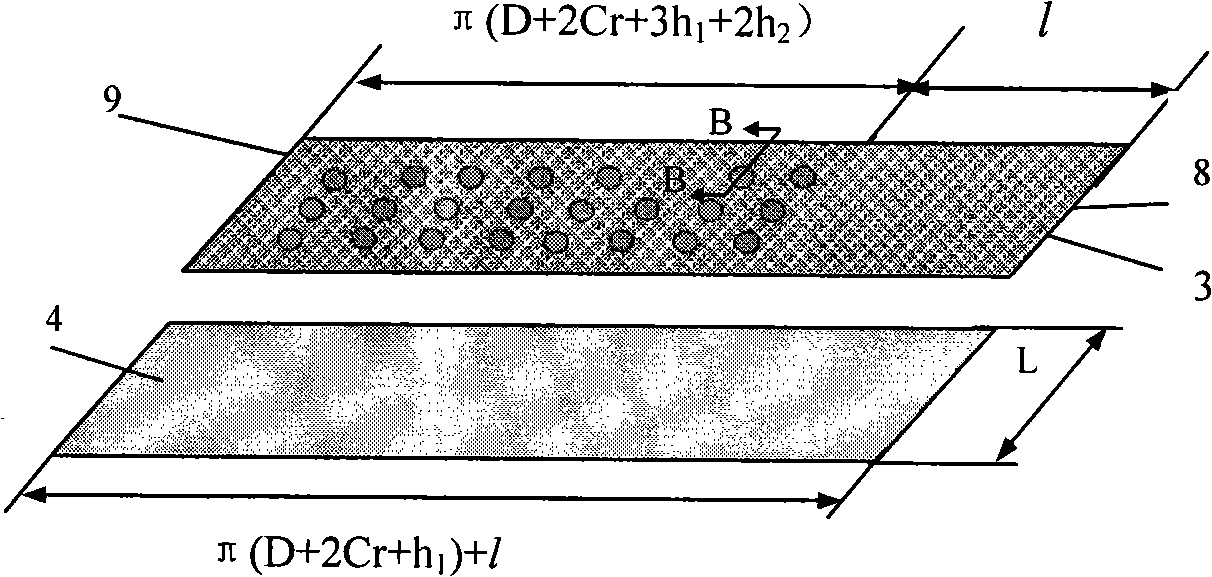

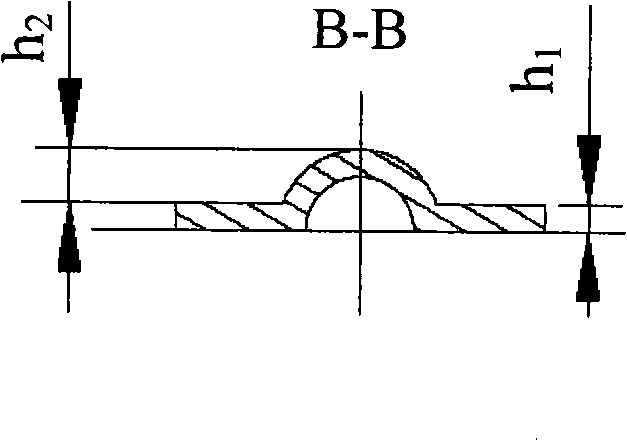

[0014] like figure 1 , figure 2 As shown, in the present invention, a slot 2 tangent to the inner diameter of the shaft hole is machined on the bearing body 1 by wire cutting, so that one end of the foils 3 and 4 can be inserted into it at the same time and the foils enter the shaft hole in a tangential manner. , to avoid the easy bending of the foil when entering in the axial way, so that the foil can fit better with the inner wall of the shaft hole. A threaded hole is processed on the outer edge of the bearing body 1 perpendicular to the card slot 2, so that the fastening screw 5 can be screwed in to compress one end of the foil embedded in the card slot. It has been fully shown by many experiments that this tangentially loaded The method is far superior to the method of loading after radial winding.

[0015] The foil material is berylli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com