Dc electric machine temperature test apparatus

A technology of DC motor and temperature rise test, which is applied in the direction of motor generator test, etc. It can solve the problems of difficult realization of motor temperature rise test and slow dynamic response of the tested DC motor, and achieve rapid temperature rise test and simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with specific drawings and embodiments.

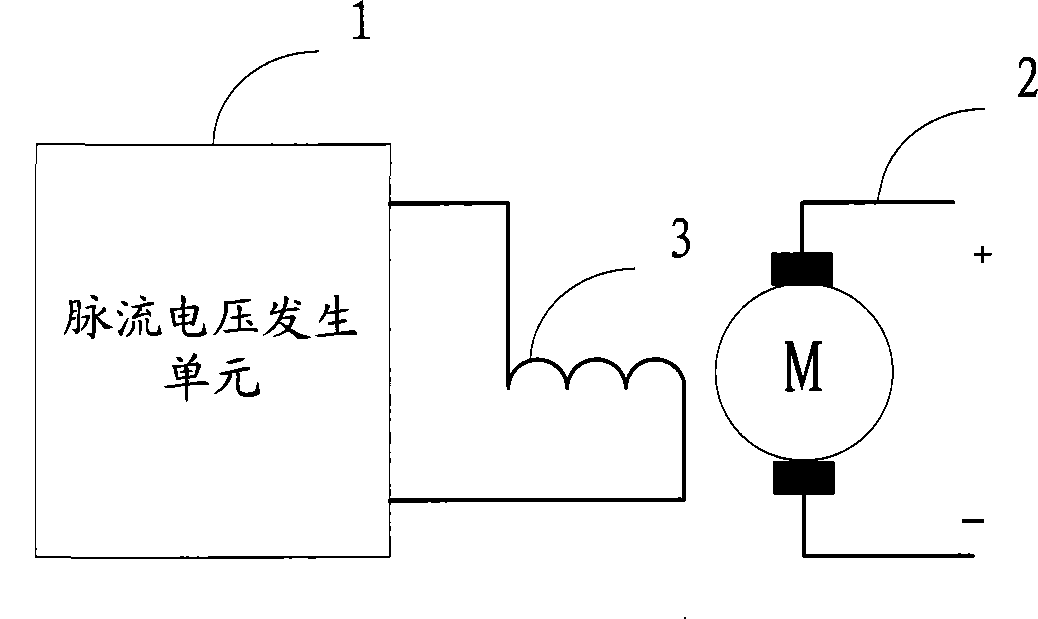

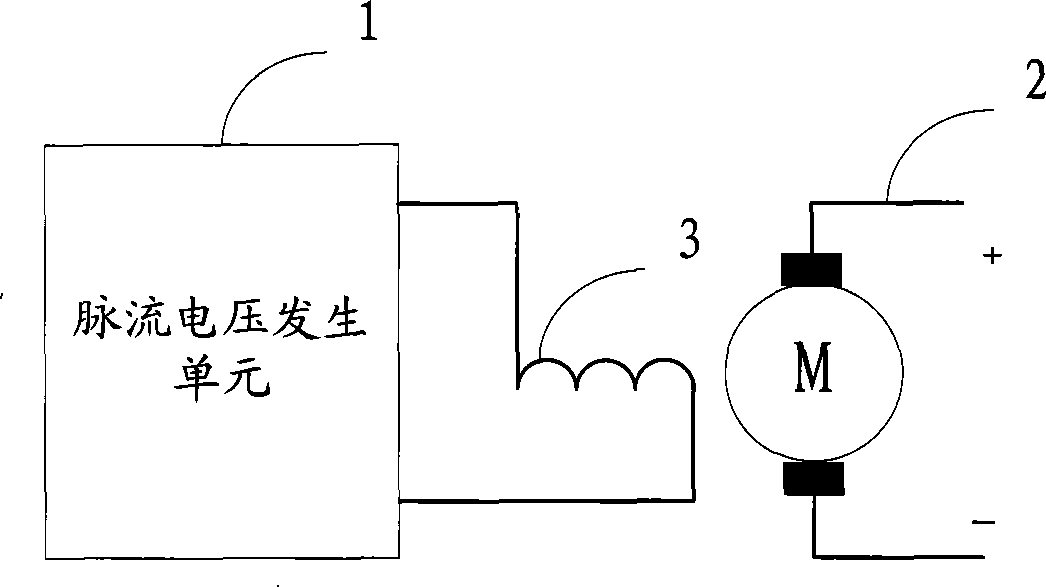

[0038] Referring to FIG. 2 , it is a structural diagram of a temperature rise test device for a DC motor according to an embodiment of the present invention.

[0039] The DC motor temperature rise test device described in the embodiment of the present invention includes a pulse current voltage generating unit 1 and a DC motor 2 to be tested.

[0040] The output terminal of the pulse voltage generating unit 1 is connected to both ends of the excitation winding 3 of the DC motor 2 under test. The pulsating voltage generating unit 1 provides the pulsating voltage for the DC motor 2 under test. The pulsating voltage is formed by superimposing a DC voltage component and a sinusoidal AC voltage component by the pulsating voltage generating unit 1 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com