Location grid with long direction eddy generator

A longitudinal vortex generator and spacer grid technology, applied in the field of spacer grids, can solve the problems of increased channel pressure drop, increased fluid resistance, etc., and achieve the effect of increasing heat transfer capacity and improving comprehensive heat transfer capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

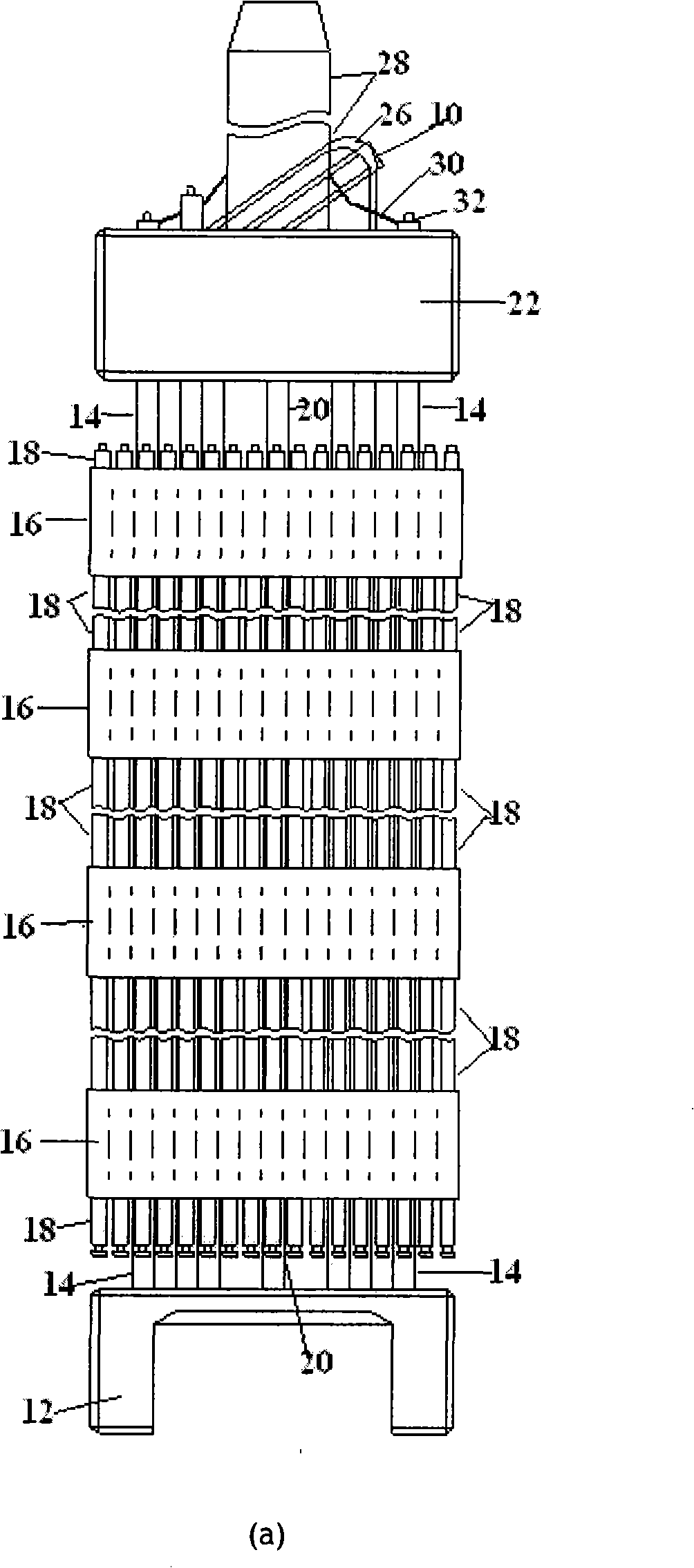

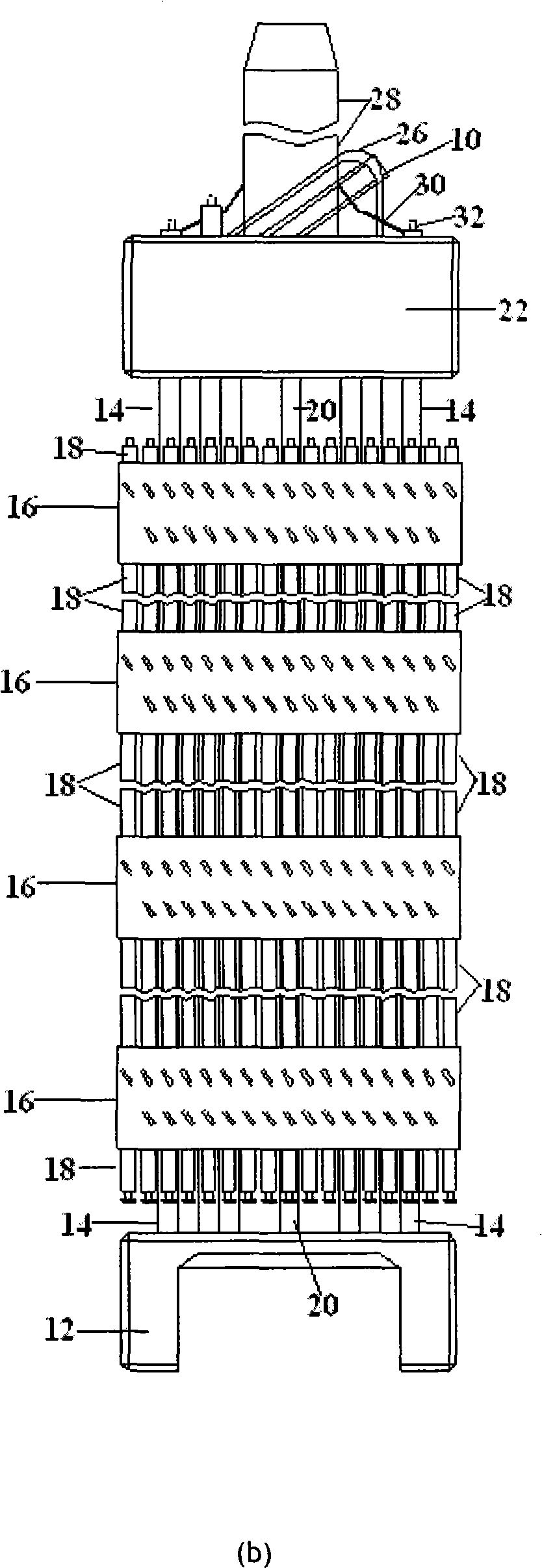

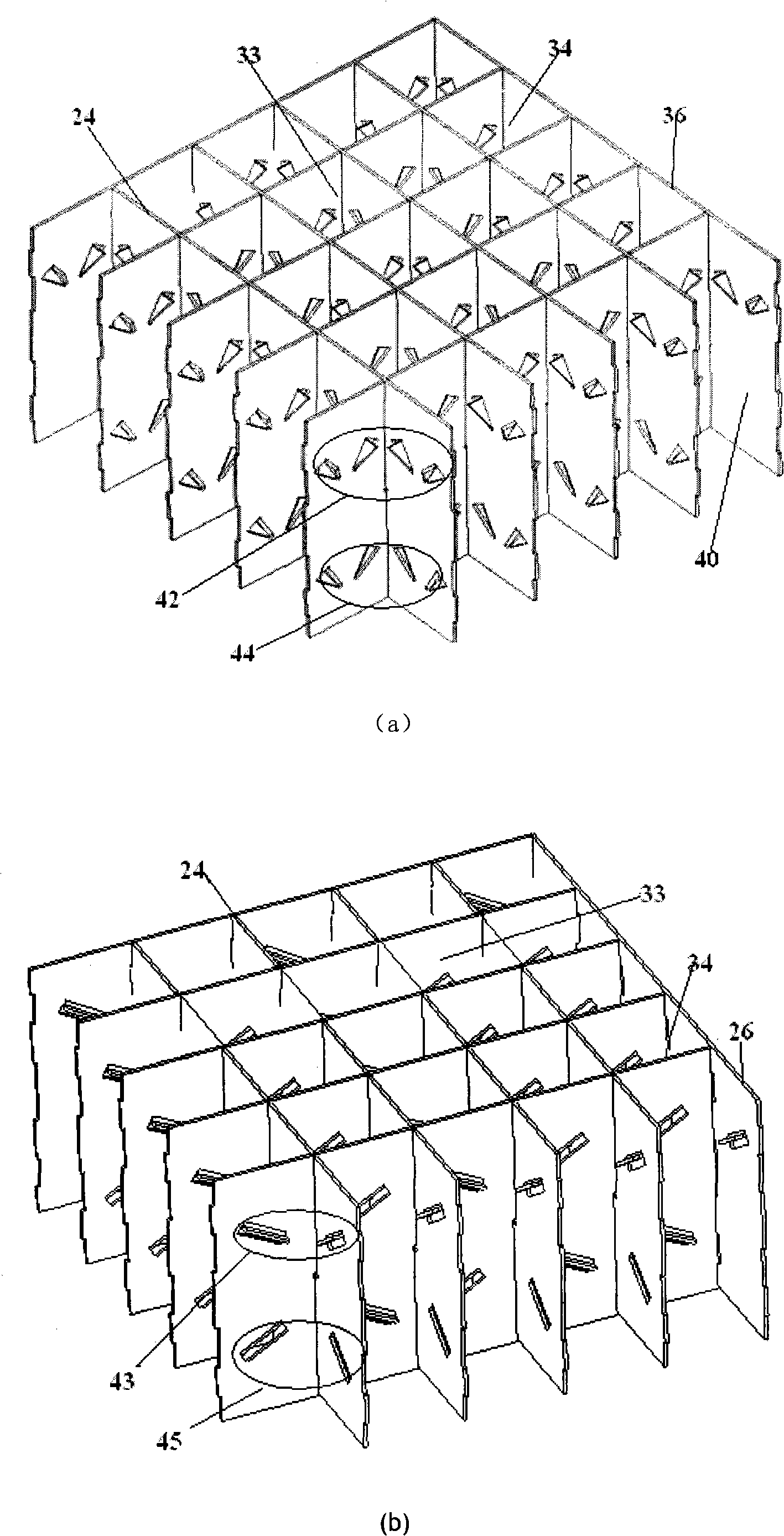

[0030] refer to figure 1 (a) and figure 1 As shown in (b), the fuel assembly 10 is made up of the lower structure or the lower nozzle base 12, the control rod guide tube 14, the spacer grid 16, the fuel rods 18, the representative tube 20 and the upper structure or the upper nozzle base 22. The lower tube base 12 is used to support the components seated on the lower core plate (not shown) of the core (not shown); the control rod guide tube 14 extends upward from the lower tube base 12; the transverse spacer The frame 16 is used to provide lateral support for the fuel rods arranged in a certain way, and the upper tube base 22 is connected to the upper end of the guide pipe 14 to form a complete assembly to perform conventional operations without damaging the fuel assembly components. Both the lower tube base 12 and the upper tube base 22 have a connecting plate, and holes are opened on the plate for liquid coolant (eg, water) to flow therethrough. In place within the box defi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com