Nail extractors

A technology of nails and nails, which is applied in the field of nail extractors, can solve the problems of failure to pull out, difficult to remove the nails, unable to fix the nails completely, etc., and achieves the effect of convenient operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

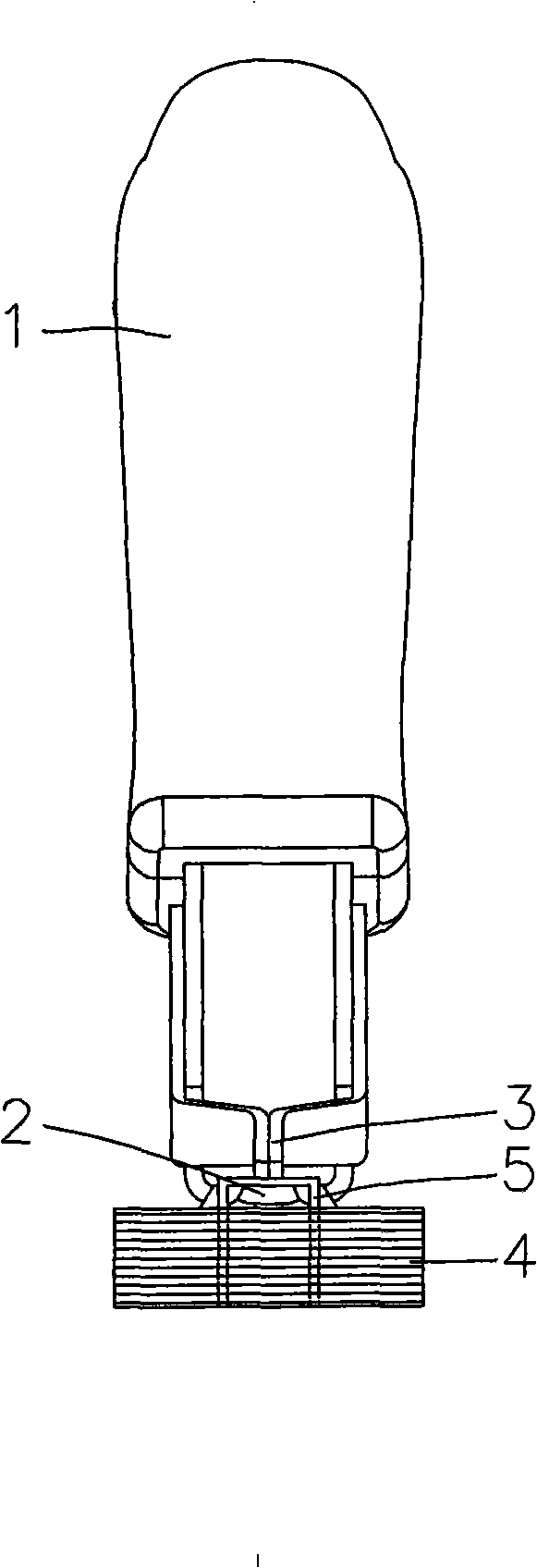

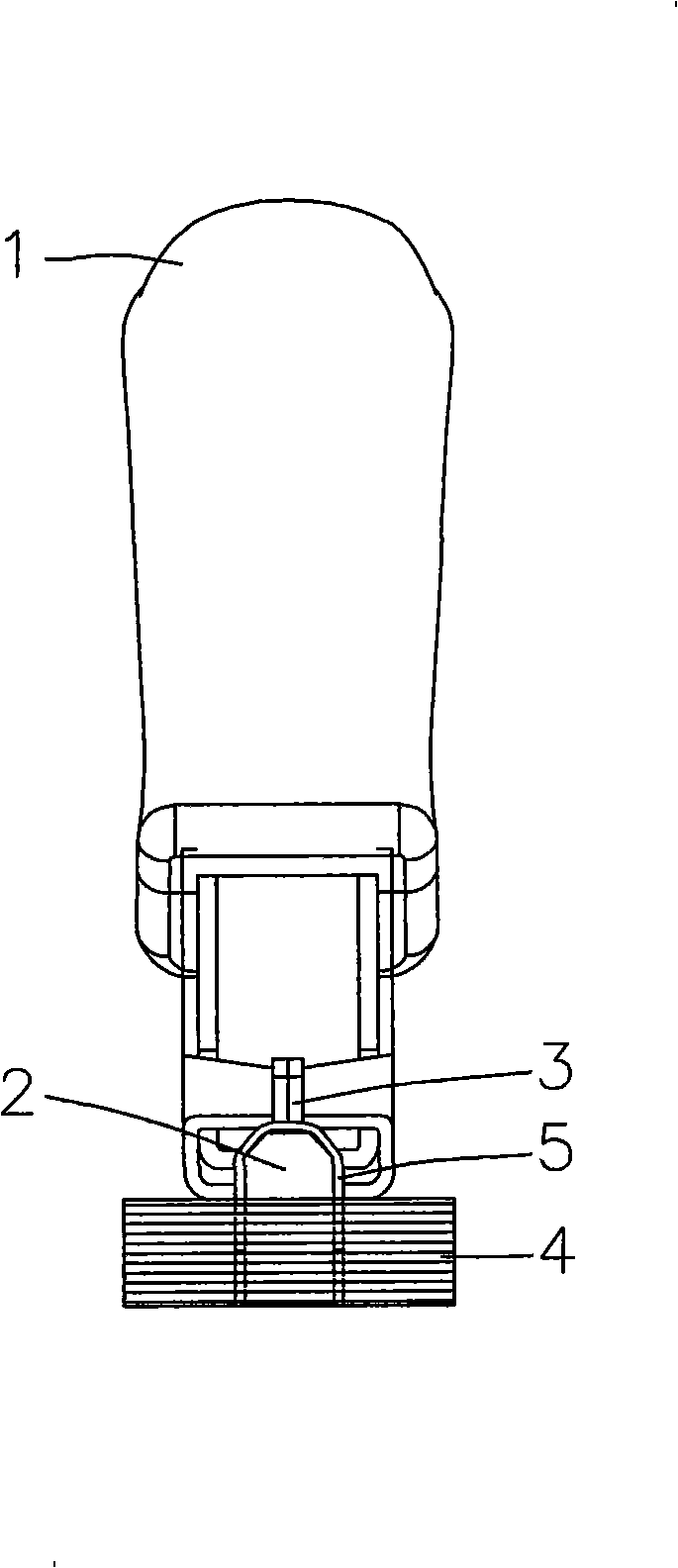

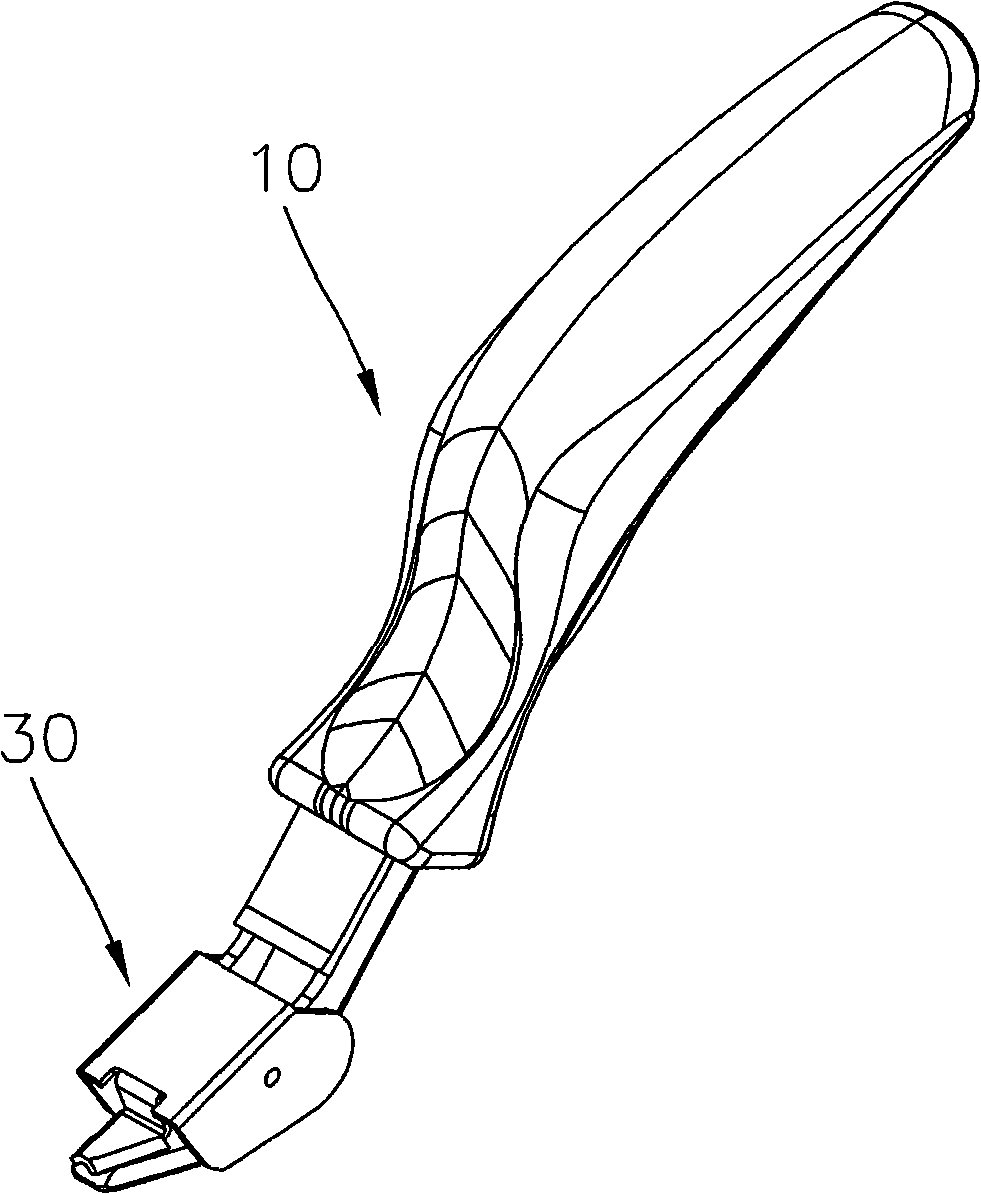

[0047] refer to image 3 Referring to Fig. 5, the present invention includes a handle 10, a nail puller 20 and a nail presser 30; wherein:

[0048] The handle 10 has a first end and a second end. The first end forms a grip portion 11 for the user to hold, and the second end of the handle 10 defines a coupling groove 12 . The handle 10 has a blocking piece 13 extending from the upper side of the open end of the coupling groove 12 .

[0049] The nail pulling member 20 is fixed at one end of the handle 10 to achieve the effect of pulling out the nail needle 90 . The nail pulling member 20 has a U-shaped structure, and has shaft holes 21 on two side walls 201 thereof for passing a pivot shaft 22 . The front part of the nail pulling part 20 is provided with a nail pulling part 23, which is used to pull out the nail pins 90 that are nailed on the paper 91 (or wood). Tilted structure.

[0050] The rear section of the nail pulling member 20 forms a joint portion 24 for inserting a...

Embodiment 2

[0063] refer to Figure 12 , is the second embodiment of the present invention. This embodiment is substantially the same as the above-mentioned embodiments, the difference lies in that a nail-pulling hole 231 is defined in the nail-pulling portion 23 . The nail-pulling hole 231 is used for the user to pull out the nails that still have one-side stitches left in the paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com