Industrial nano-water and uses thereof

A nano-water and industrial technology, which is applied in the chemical industry, water, sustainable manufacturing/processing, etc., can solve the problems of no affinity between crystal nuclei and can no longer participate, and achieve enhanced penetration, increased energy, and fast evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

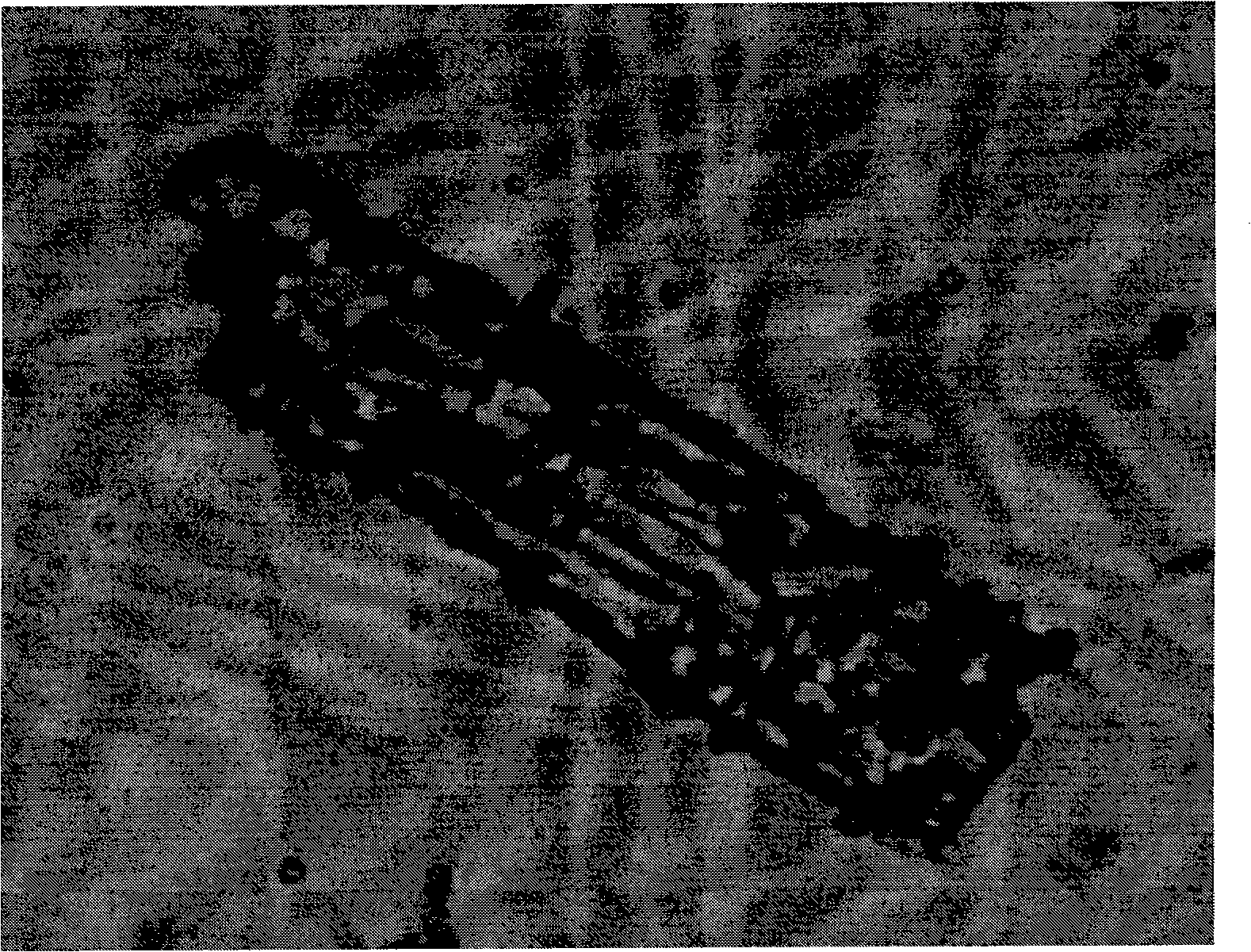

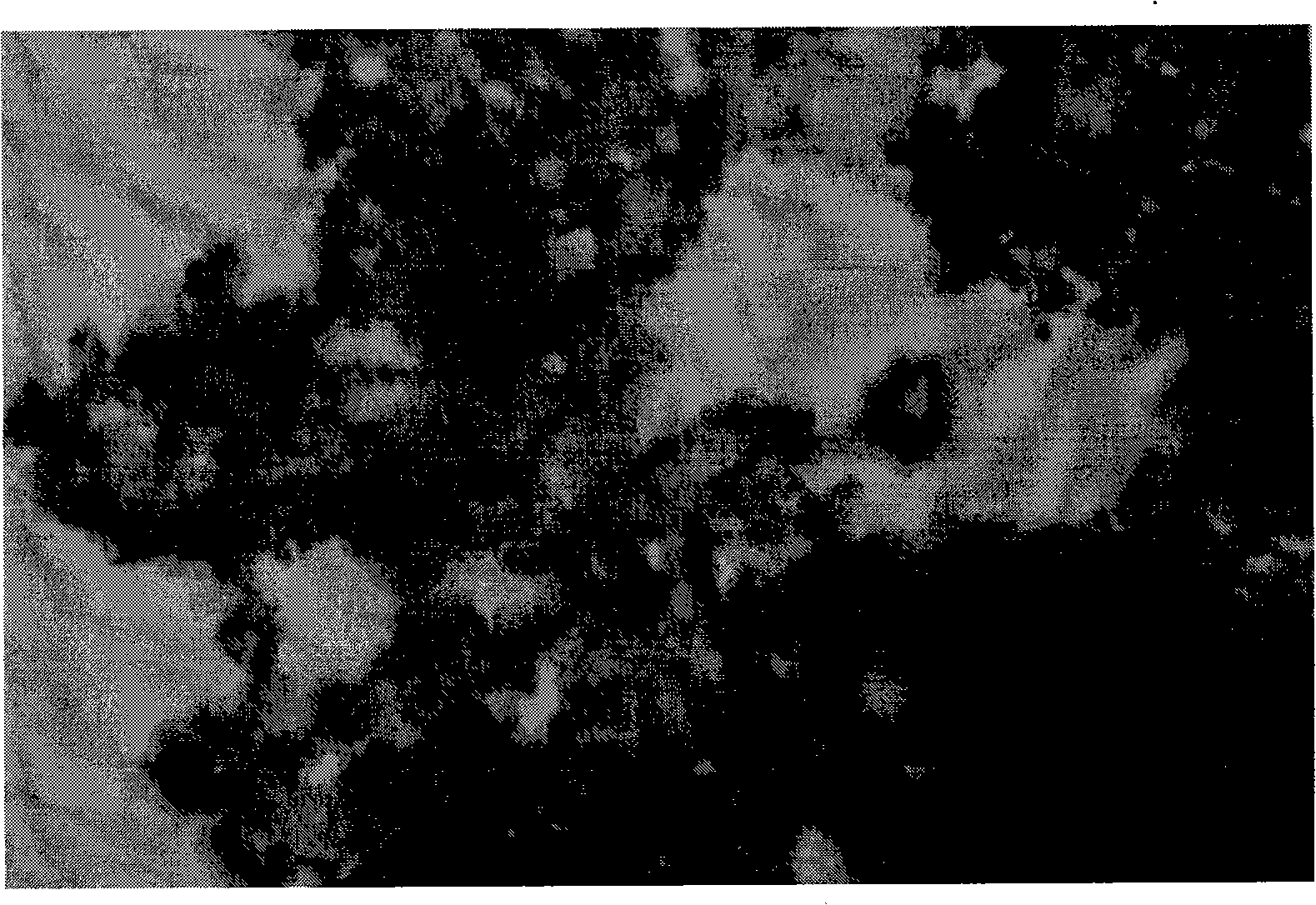

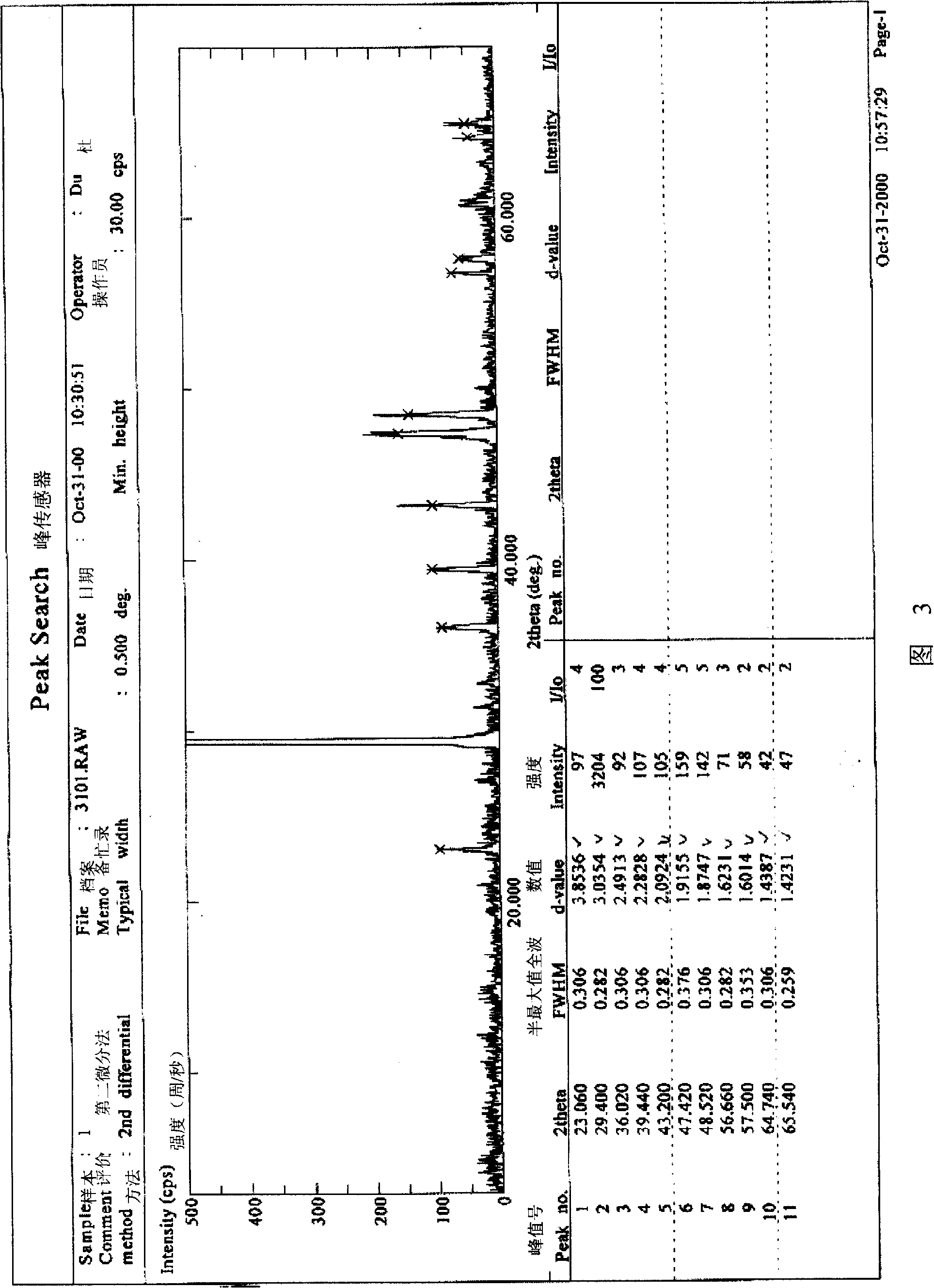

Image

Examples

Embodiment

[0039] The industrial nano water of the present invention can be obtained by passing softened water, demineralized water or industrial pure water meeting the boiler water treatment water quality standard, that is, water hardness ≤0.03mmol / L, through the paramagnetic resonance field system with energy synergy effect.

[0040] The action mechanism of the paramagnetic resonance field system is to use permanent magnetic field rays, spontaneous electron flow, particle flow, and photon flow to co-excite RF-BCC nanomaterials; at the same time, the energy of the excitation source also directly acts on water heteroions (atomic numbers below 25 Substance) produces a synergistic effect of "energy". Therefore, the resonance effect of the paramagnetic resonance field with the compound "energy" synergistic effect triggers the "resonance" movement in the water molecule, affects the rearrangement mechanism of the hydrogen bond network, and realizes the change of the cluster structure of the wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Scale | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com