Accurate method for verifying pressure of low-pressure instrument

A technology of instrument accuracy and pressure, applied in the field of low-pressure instrument pressure calibration, it can solve the problems of large pressure fluctuation, difficult pressure control, slow pressure increase, etc., to achieve the effect of small pressure fluctuation, easy pressure control, and rapid pressure increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

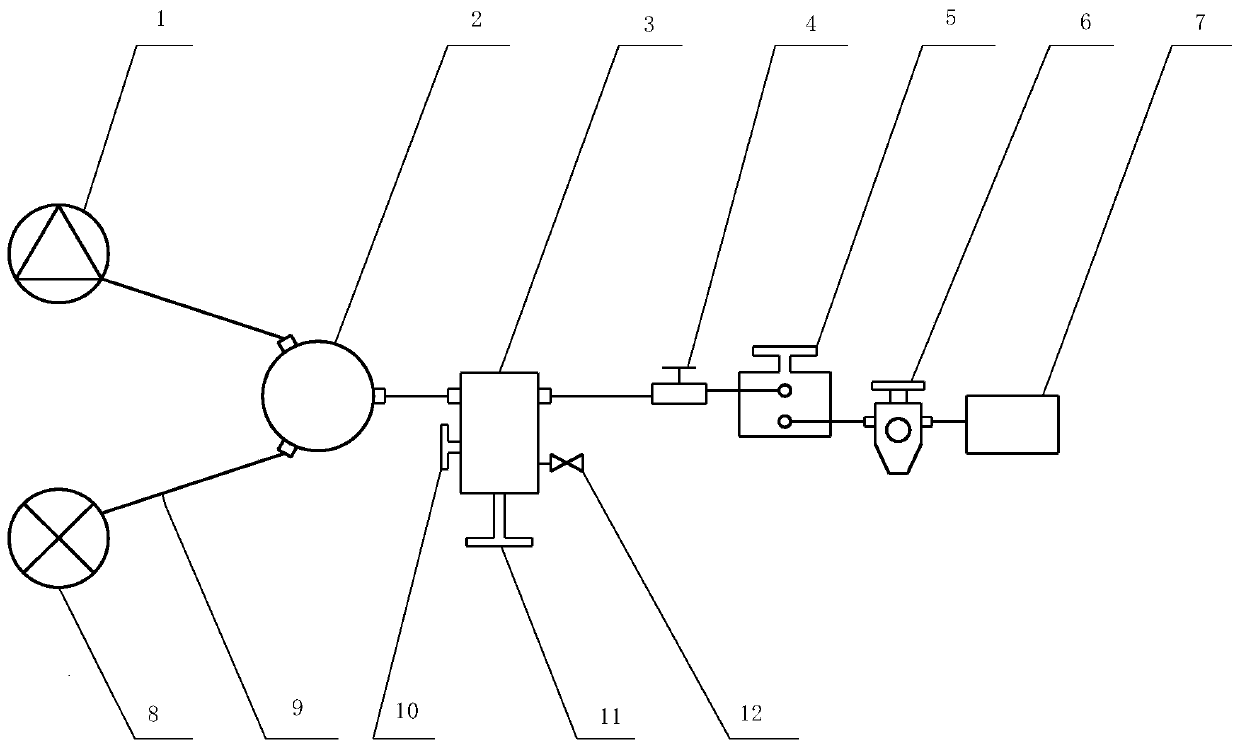

[0021] like figure 1 As shown, the accurate method of checking low-pressure gauge pressure of the present invention comprises the following steps:

[0022] (a), connect the standard meter 1 and the meter 8 to be calibrated with the verification device respectively, and the verification device includes: a tee 2 connected in sequence, a pressure trimmer 3, a stop valve 4, a constant value device 5, a filter reducing Pressure valve 6 and pressure source 7, precision fine-tuning handle 10, fine-tuning handle 11 and pressure relief valve 12 are installed on the pressure trimmer 3, the standard meter 1 and the calibrated meter 8 are respectively connected with the two ports of the tee 2, the standard meter 1 , Calibrated meter 8, tee 2, pressure trimmer 3, stop valve 4, constant value device 5, filter pressure reducing valve 6 and pressure source 7 are connected through connecting pipe 9, which is 4mm in diameter Nylon tube;

[0023] (b), the pressure source 7 provides a rated pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com