Composite plastic film water cavity type solar flat-board heat collector

A flat-plate collector and composite plastic technology, applied in solar thermal devices, solar thermal power generation, heating devices, etc., can solve the problems of reducing heat conduction efficiency, prone to defective products, product scrapping, etc. Defective rate, overall lightweight effect

Inactive Publication Date: 2008-10-15

贺晓华

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the prior art, the water cavity of the solar flat collector is mostly made of metal materials, such as copper, aluminum, etc., and the solar flat collector water cavity with such a structure has many disadvantages: 1. The cost of the metal material is high, The production process is complicated, and defective products are prone to appear; 2. The service life is short, and the scale generated in the metal material water cavity of the collector is difficult to clean and will reduce the heat transfer efficiency; 3. When used in winter, the metal material water cavity is easy to Frost cracking occurs, which brings a lot of inconvenience to users and scrapping of products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

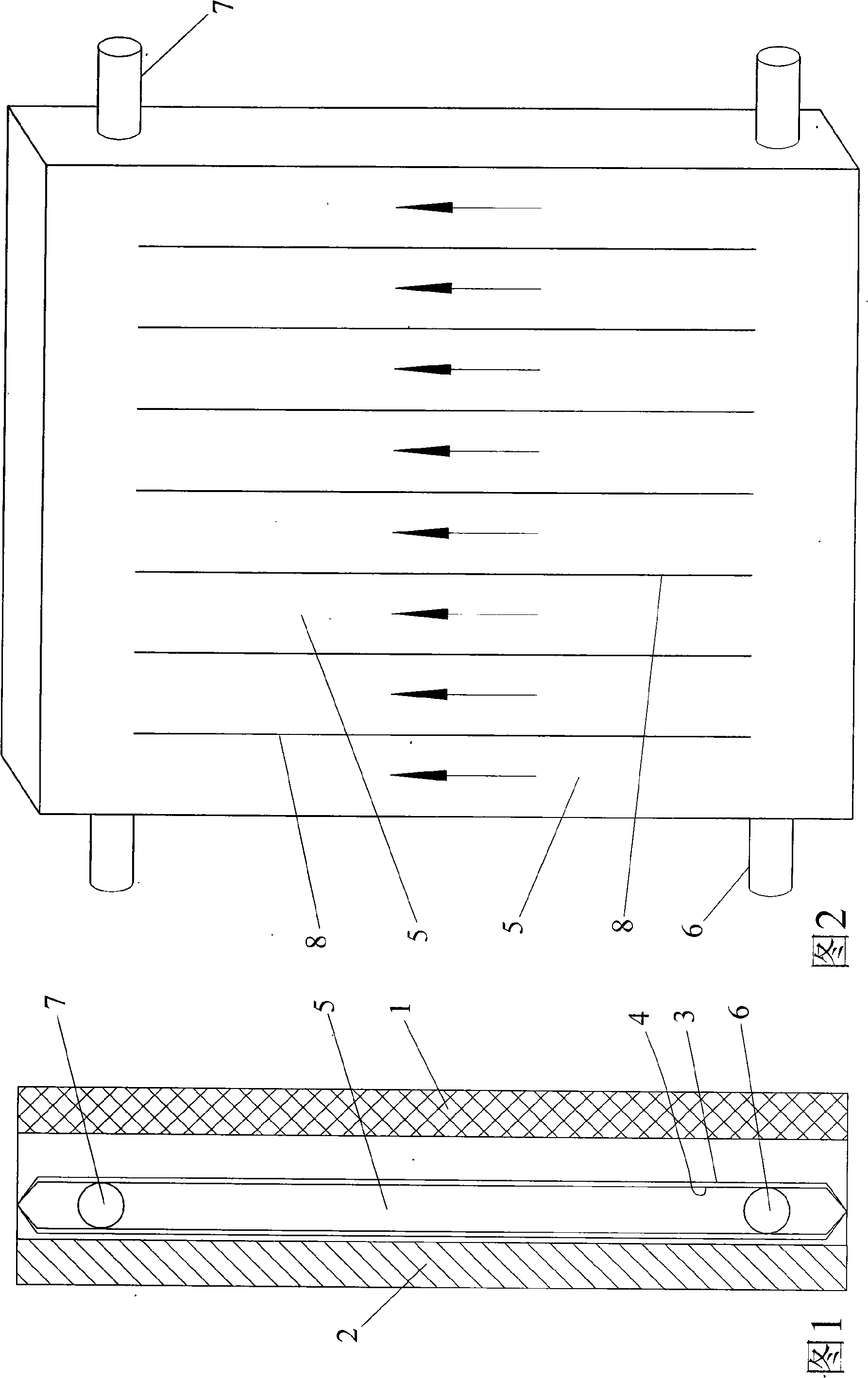

The invention discloses a composite plastic film water jacket solar panel heat collector. A water jacket component is arranged between a sunlight plate and an insulating course, wherein, the water jacket component consists of a double-layer composite plastic film which is vertically provided with a plurality of intensified scalding sticking lines to ensure that the double-layer composite plastic film form a plurality of vertical water jackets, the upper ends of the water jackets are communicated one another and are communicated to water outlets, the lower ends of the water jackets are communicated one another and are communicated to water inlets. The outer layer of the double-layer composite plastic film is an ultravioresistant black non-luminous plastic film; the inner layer of the double-layer composite plastic film is an edible plastic film. The plastic material has low cost and simple production technique and is easy to reduce the defective rate; the hot water inside the plastic material water jacket is not easy to form scale, the service life is up to ten years; when the heat collector is used in the winter, the water jacket is not easy to frost crack because the plastic film is elastic, thereby bringing convenience to a user; the whole is lighter.

Description

Composite plastic film water cavity solar flat plate collector technical field The invention relates to a solar flat plate heat collector, in particular to a composite plastic film water cavity type solar flat plate heat collector. Background technique In the prior art, the water cavity of the solar flat plate heat collector is mostly made of metal materials, such as copper material, aluminum material, etc. The water cavity of the solar flat plate heat collector with such a structure has many disadvantages: 1. The cost of metal materials is high; The production process is complicated, and defective products are prone to occur; 2. The service life is short, and the scale generated in the water cavity of the metal material is difficult to clean and reduces the heat conduction efficiency when the collector is used for a long time; 3. When used in winter, the water cavity of the metal material is easy to Frost cracking phenomenon occurs, which brings a lot of inconvenience to ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F24J2/04F24J2/46

CPCY02E10/44

Inventor 贺晓华

Owner 贺晓华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com