Vertical type calcining kiln falling control device

A control device and calcining kiln technology, applied in vertical furnaces, furnaces, lighting and heating equipment, etc., can solve problems such as raw burning, material sintering, over-burning, etc., to ensure high quality, improve production efficiency, and eliminate raw burning and the effect of overheating

Inactive Publication Date: 2008-10-15

黄官禹

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved by the present invention is to provide a vertical calcination kiln blanking control device to solve the problems of sintering, raw burning and over-burning of materials

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

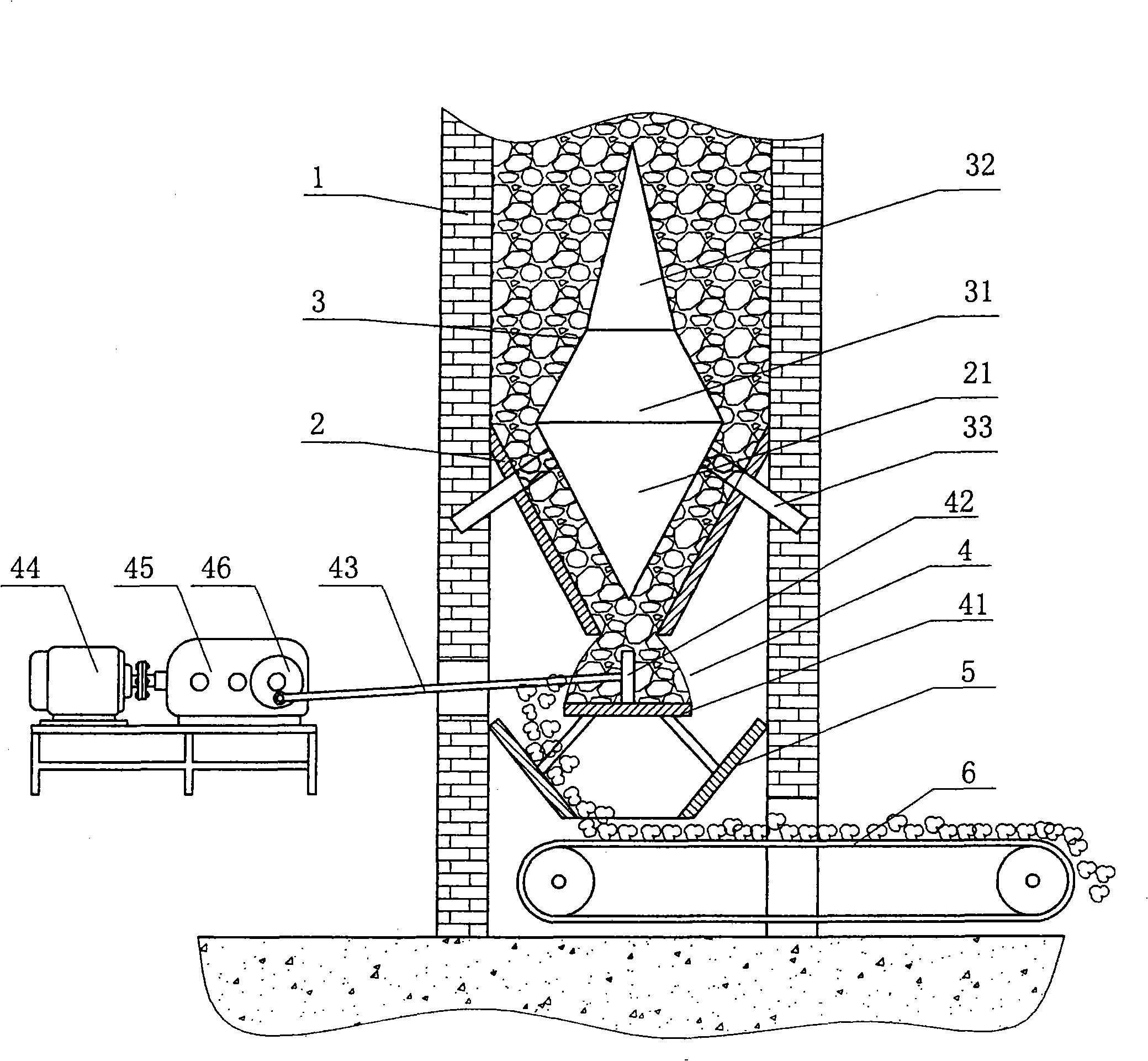

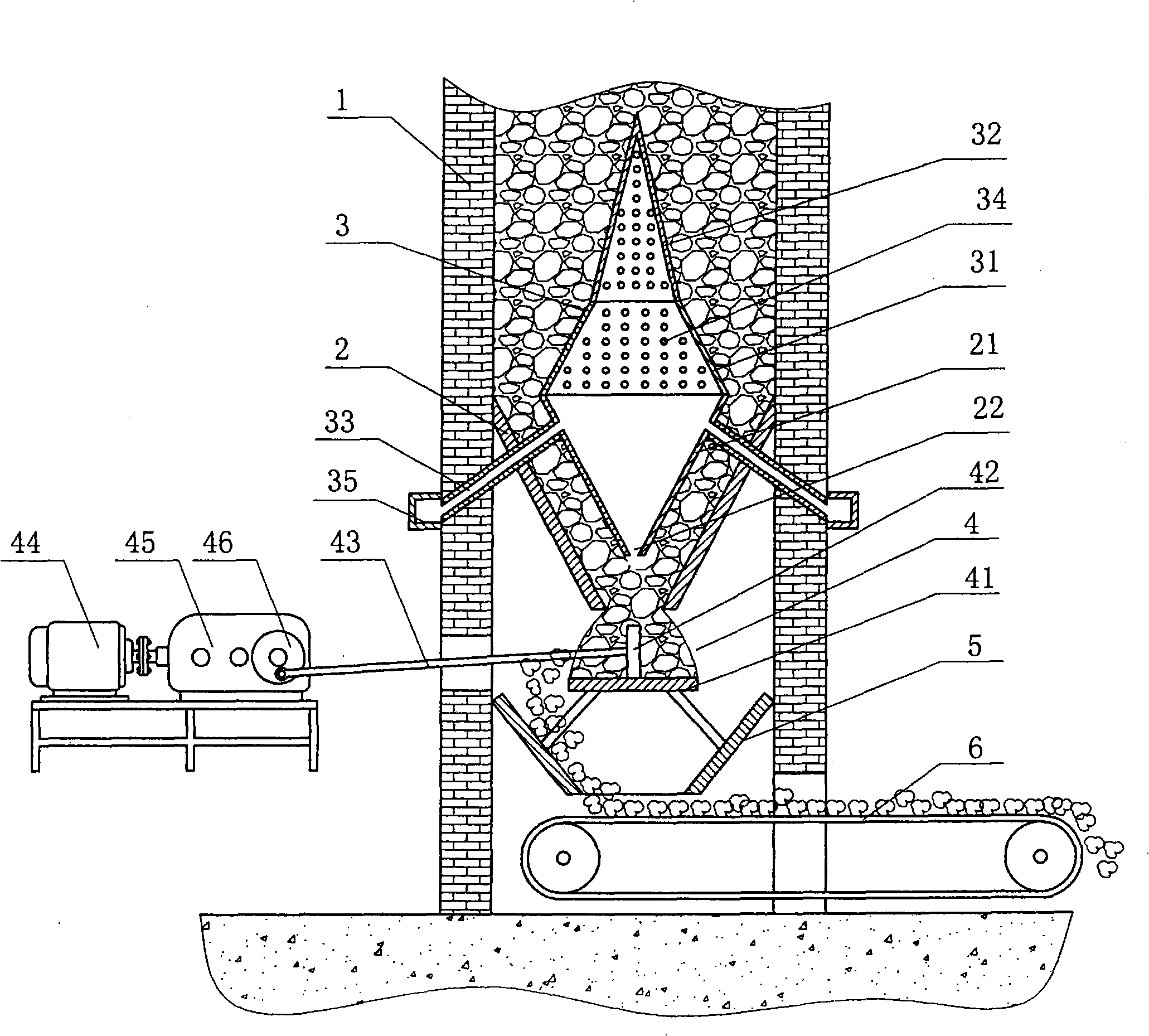

The invention discloses a vertical calcining kiln blanking control device, comprising a kiln body, wherein, the lower part of a cooling area inside the kiln body is provided with a funnel-shaped discharging car, the upper part of the discharging car is provided with a separatory cone with an upward tip, the bottom of the separatory cone is fixed with a guide cone, a cone supporting rack is arranged between the guide cone and the kiln body, the guide cone and the discharging car have the same conicity, the lower part of a discharging opening of the discharging car is provided with a continuous discharging device; the arrangement of the separatory cone and the guide cone controls the material to fall down on every horizontal surface inside the kiln at the same speed, thereby completely avoiding the less burnt and over burnt phenomena as well as the retention in dead angle and agglomeration and guaranteeing the high quality of the product; the arrangement of the continuous discharging device controls the falling speed of the material; the device realizes the continuous production and improves the production efficiency.

Description

Vertical calciner blanking control device technical field The invention relates to a vertical calcination kiln, in particular to a device for controlling the uniform fall of calcined materials in the vertical calcination kiln. Background technique At present, all vertical kilns (including lime calcining kiln, magnesia calcining kiln, etc.) due to the structure of the blanking part, the charge can only fall from the center of the kiln, and the falling speed of the material close to the inner wall of the kiln is slow or stagnant, resulting in material Uneven calcination, raw burning or over-burning will affect the quality of the finished product, and the space around the kiln is not fully utilized, which greatly reduces the production efficiency of the kiln, wastes resources and pollutes the environment. Contents of the invention The technical problem to be solved by the present invention is to provide a vertical calciner blanking control device to solve the problems of s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Applications(China)

IPC IPC(8): F27B1/20F27D3/10

Inventor 黄官禹

Owner 黄官禹

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap