Lifting anti-falling operating platform for constructional engineering

An operation platform and construction engineering technology, which is applied in the direction of construction, building structure, house structure support, etc., can solve the problem of large tensile force of the insurance wire rope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

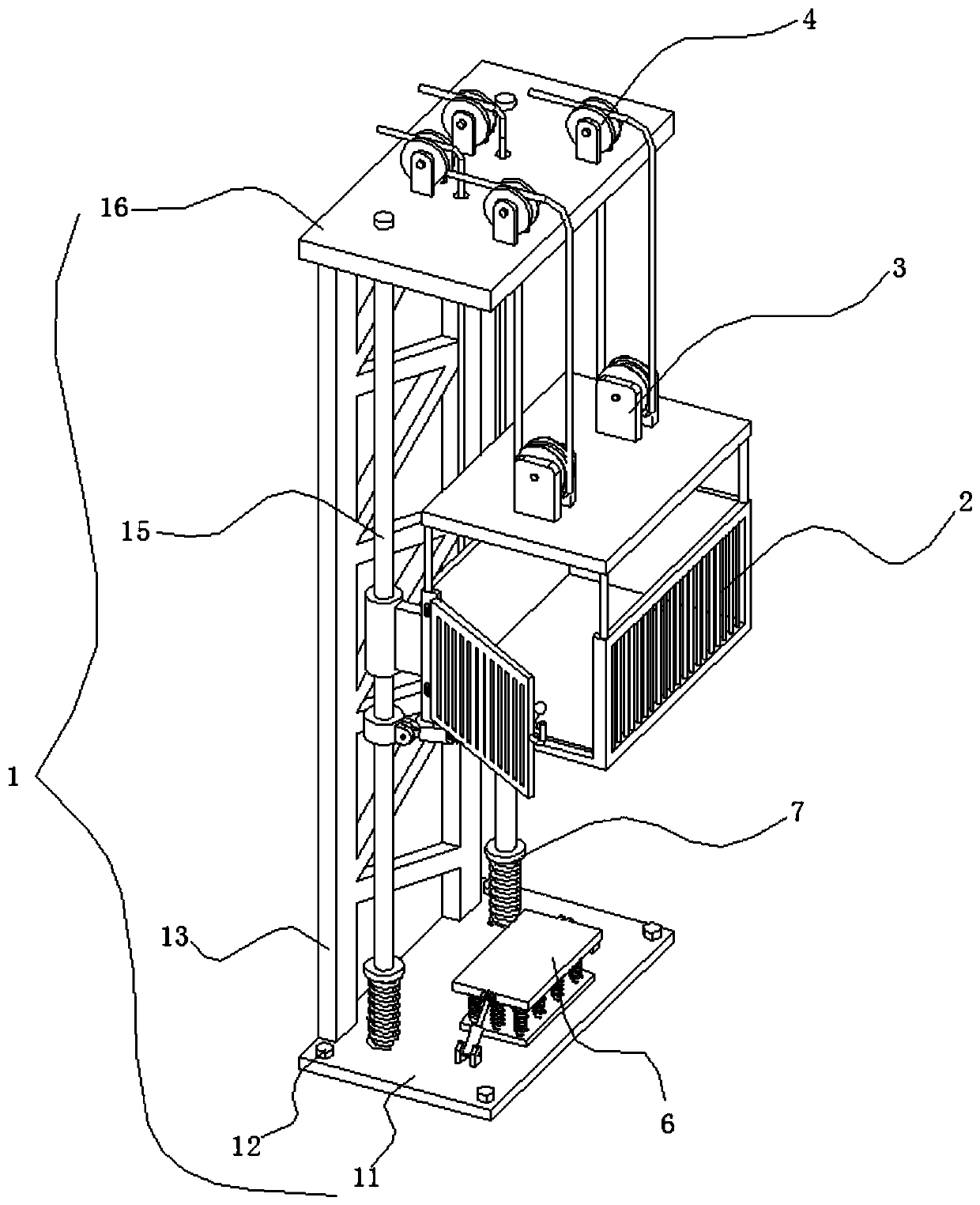

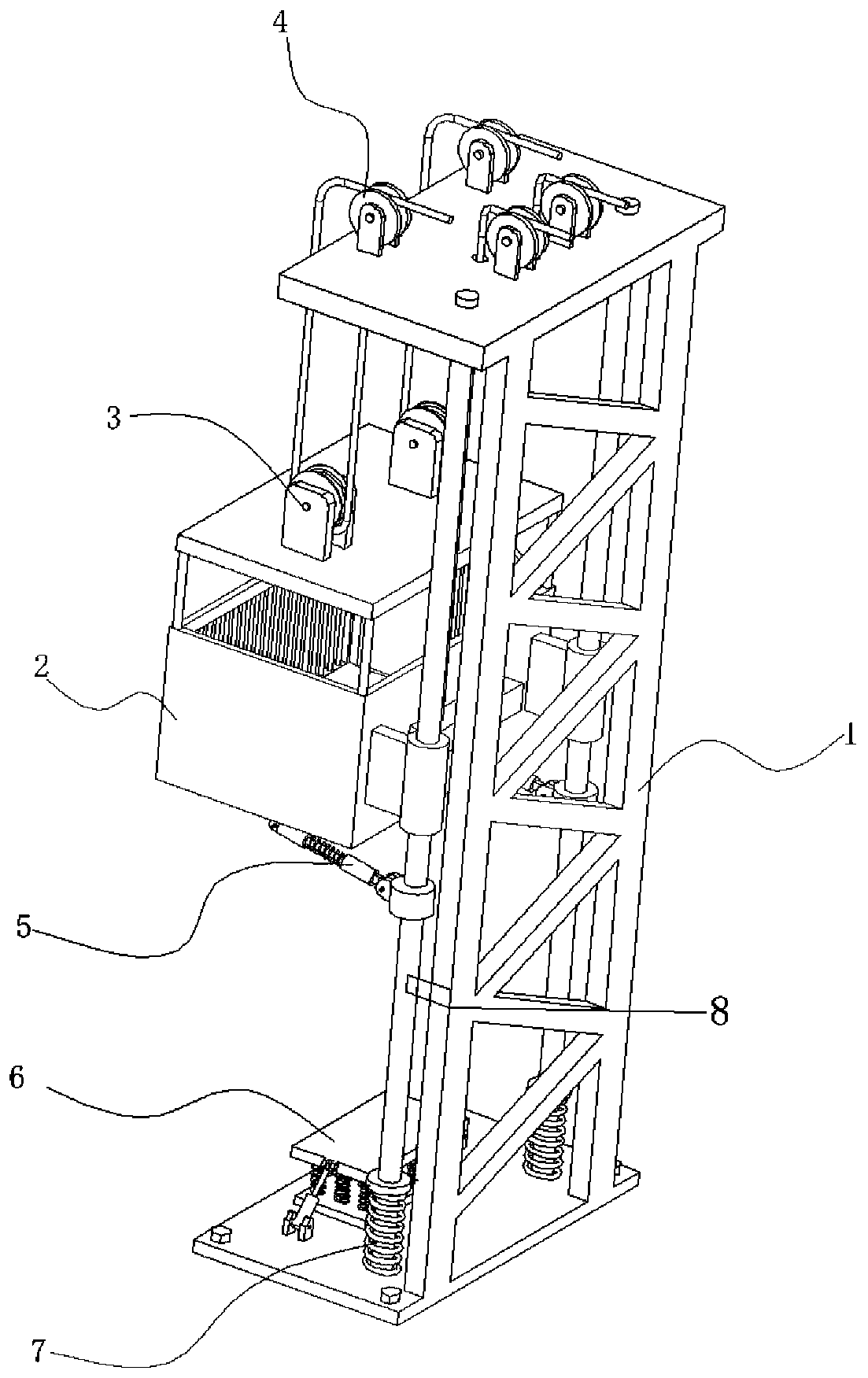

[0037] refer to Figure 1-3, a lifting anti-fall operation platform for construction engineering, including a mounting mechanism 1, the mounting mechanism 1 includes a base 11, a number of anchor bolts 12, a mounting frame 13, two guide rail columns 15 and a top seat 16, the base 11 passes through the anchor bolts 12 is fixedly installed on the ground, the bottom of the mounting frame 13 is fixedly mounted on the base 11, the top of the mounting frame 13 is fixedly connected with the top base 16, and two guide rail posts 15 are fixedly installed between the top base 16 and the base 11, and two Guide rail columns 15 are arranged in parallel;

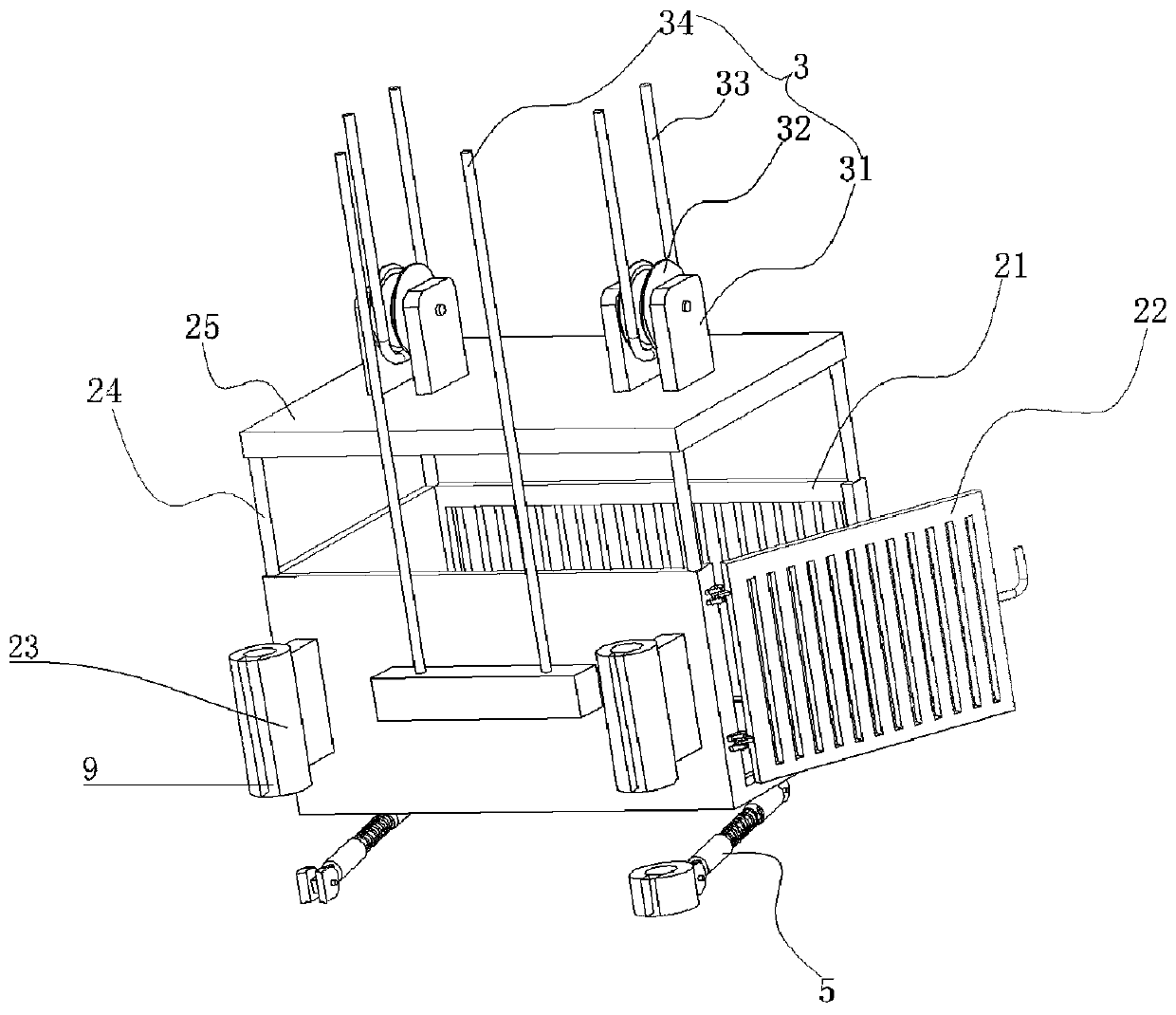

[0038] The platform assembly 2 is installed on the rail column 15, and the platform assembly 2 includes a support platform 21, a protective door 22, two sliding seats 23, several connecting rods 24 and a top plate 25, and the two sliding seats 23 are respectively sleeved on the corresponding rail column 15. on, and is slidably connected ...

Embodiment 2

[0042] refer to Figure 1-4 As another preferred embodiment of the present invention, the difference from Embodiment 1 is that a guide mechanism 4 corresponding to the lifting mechanism 3 is installed on the top of the top seat 16, and the guide mechanism 4 includes two first mounting seats 41, two A first guide wheel 42, two second mounts 43 and two second guide wheels 44, the two first mounts 41 are fixedly mounted on the top of the top seat 16, and parallel to each other, the two first guide wheels 42 Rotately connect with the corresponding first mounting base 41 through pin shaft; Two mounting bases 43 are rotationally connected;

[0043] The first lifting cable 33 is set on the corresponding first guide wheel 42, and is connected with the first guide wheel 42 in transmission; the second lifting cable 34 is set on the corresponding second guide wheel 44, and is connected with the second guide wheel 44 Drive connection. The first guide wheel 42 and the second guide wheel...

Embodiment 3

[0045] refer to Figure 1-5 , as another preferred embodiment of the present invention, the difference from Embodiment 1 or Embodiment 2 is that two brake mechanisms 5 are installed on the bottom of the support platform 21, and the brake mechanism 5 includes a brake ring 51, a first set Seat 52, first spring 53, sleeve rod 54, push rod 55 and second sleeve seat 56, brake ring 51 is sleeved on the corresponding guide rail post 15, and is slidably connected with guide rail post 15; the first sleeve seat 52 One end of one end is rotationally connected with the brake ring 51 through a hinge, and the two ends of the sleeve rod 54 are inserted into the first sleeve seat 52 and the second sleeve seat 56 respectively, and the sleeve rod 54 is connected to the first sleeve seat 52 and the second sleeve seat 56. Both are slidingly connected; the first spring 53 is sleeved on the sleeve rod 54, the push rod 55 is rotatably connected with the second sleeve 56 through a hinge, the push rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com