Electromagnetic stove time-limiting automatic switch on and off protection device

A protection device, the technology of electromagnetic cooker, applied in the direction of signal device, visible signal device, household stove/stove, etc., can solve the problem of not being able to power off automatically, and achieve the effect of avoiding manual power off and reducing the possibility of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

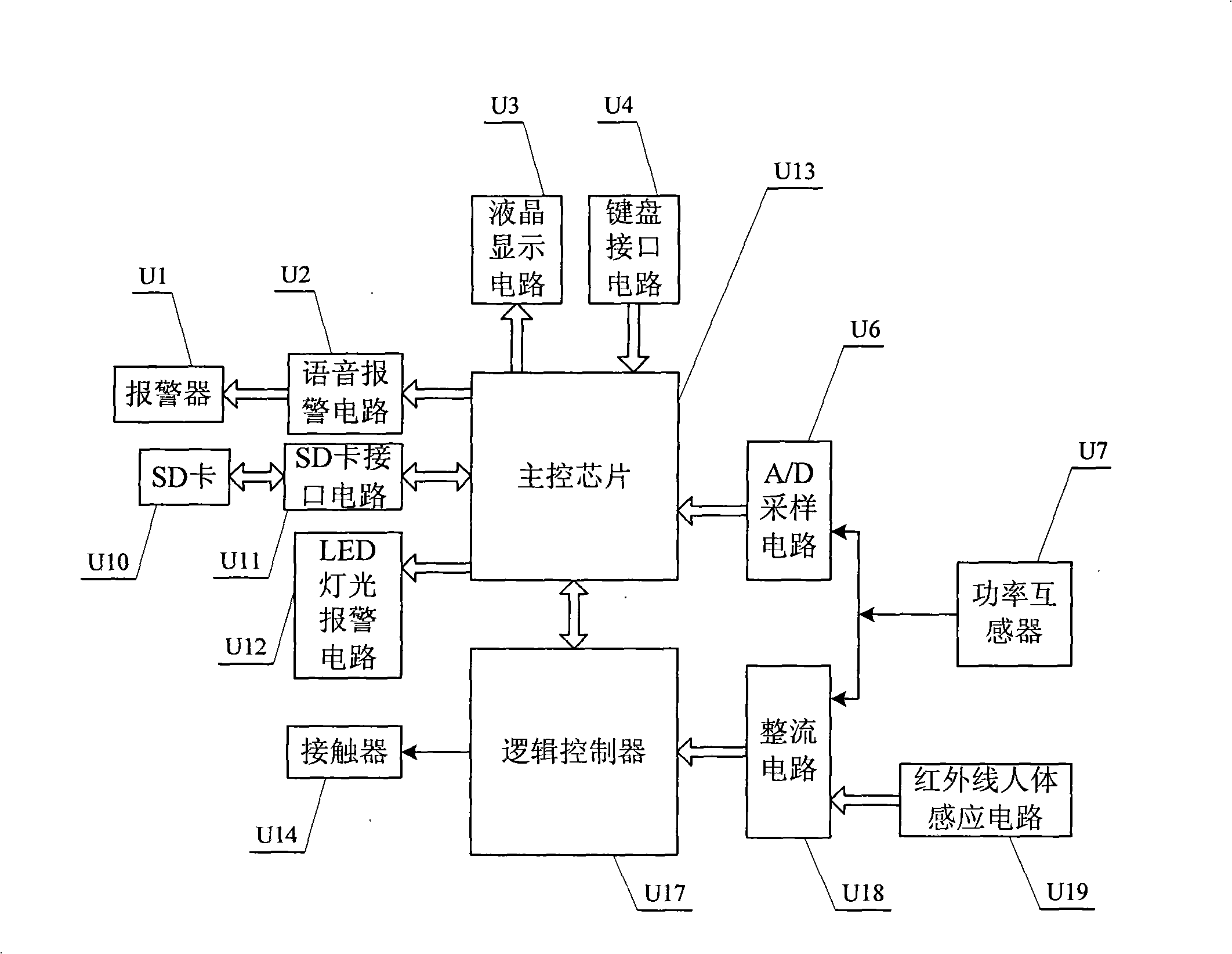

[0014] Specific implementation mode one: see figure 1 , this embodiment consists of the following units:

[0015] The power sensor U7, when monitoring the working signal of the electromagnetic cooker, sends the start-up signal of the electromagnetic cooker to the PLC programmable logic controller U17 through the rectifier circuit U18, and at the same time sends the output signal of the power sensor U7 through the A / D sampling circuit U6 Convert it into A / D sampling signal and send it to the main control chip U13;

[0016] PLC programmable logic controller U17, when receiving the start power signal of the electromagnetic cooker from the power sensor U7, starts the internal timer to time the working time of the electromagnetic cooker, and after the working time ends, sends a control signal to disconnect the contactor U14, and At the same time, start the internal timer to set the power-off time. After the power-off time is over, send the control signal to make the contactor U14 ...

specific Embodiment approach 2

[0024] Specific implementation mode two: see figure 1 , this embodiment adds the following units on the basis of the specific embodiment one:

[0025] The SD card interface circuit U11 stores the automatic power-off time of each induction cooker, the unmanned time of the dining car and the consumed electric energy value in the SD card U10, and calls the information in the SD card U10 according to the requirements of the main control chip U13.

[0026] SD card U10 and SD card interface circuit U11 form an SD card storage system. The stored data includes three parts: the cumulative value of electric energy, the unmanned time of the dining car and the automatic power-off time, which can be used by operators and maintenance personnel to understand the operation of the entire system and increase system security and operational efficiency.

specific Embodiment approach 3

[0027] Specific implementation mode three: see figure 1 , this embodiment adds the following units on the basis of the specific embodiment one:

[0028] The LED light alarm circuit U12 receives the alarm signal from the main control chip U13 and starts the LED light alarm.

[0029] It can be used in conjunction with the alarm U1, or used alone or when the alarm U1 fails, to warn the staff.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com