Solid state encapsulation device of X light tube for X fluorescent spectrometer

A fluorescence spectrometer and packaging device technology, which is applied to measuring devices, parts of X-ray tubes, X-ray tube shells/containers, etc., can solve problems such as complex X-ray tube structures, pollute the environment, and inconvenient maintenance, and achieve structural Simple, easy and reliable operation, convenient installation and maintenance

Inactive Publication Date: 2008-10-15

JIANGSU SKYRAY INSTR

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a brand-new X-ray tube solid-state packaging technology for X-ray spectrometers, which can completely solve the problems of aging, high cost, short life, inconvenient maintenance, environmental pollution, Defects such as complex structure of X-ray tube

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

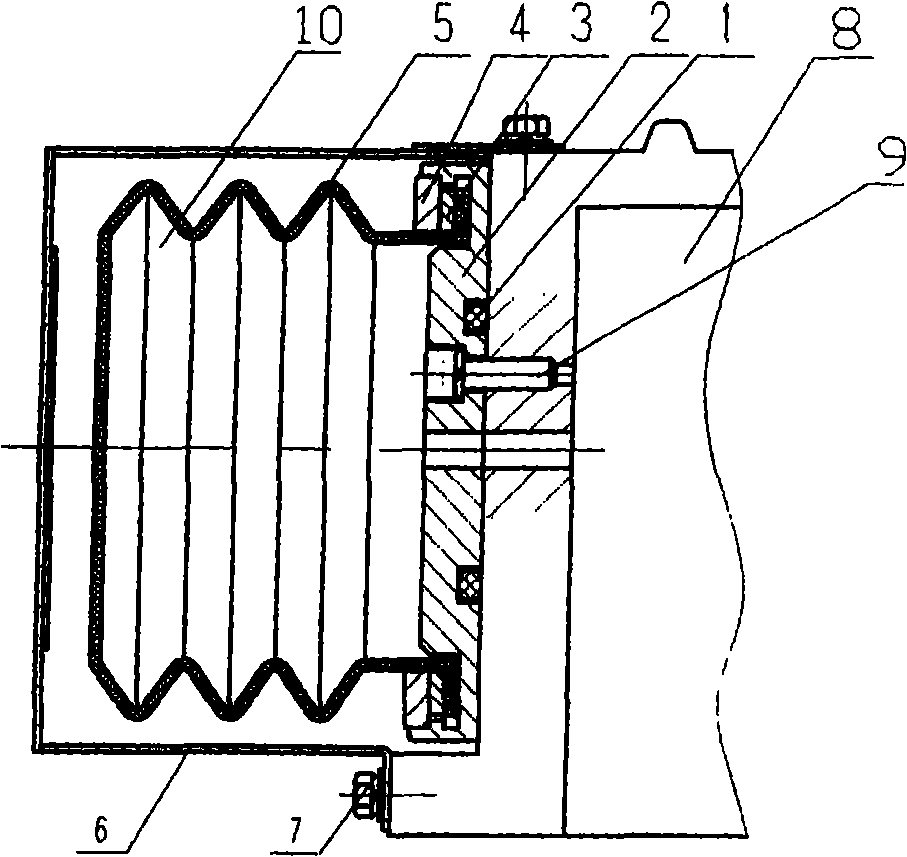

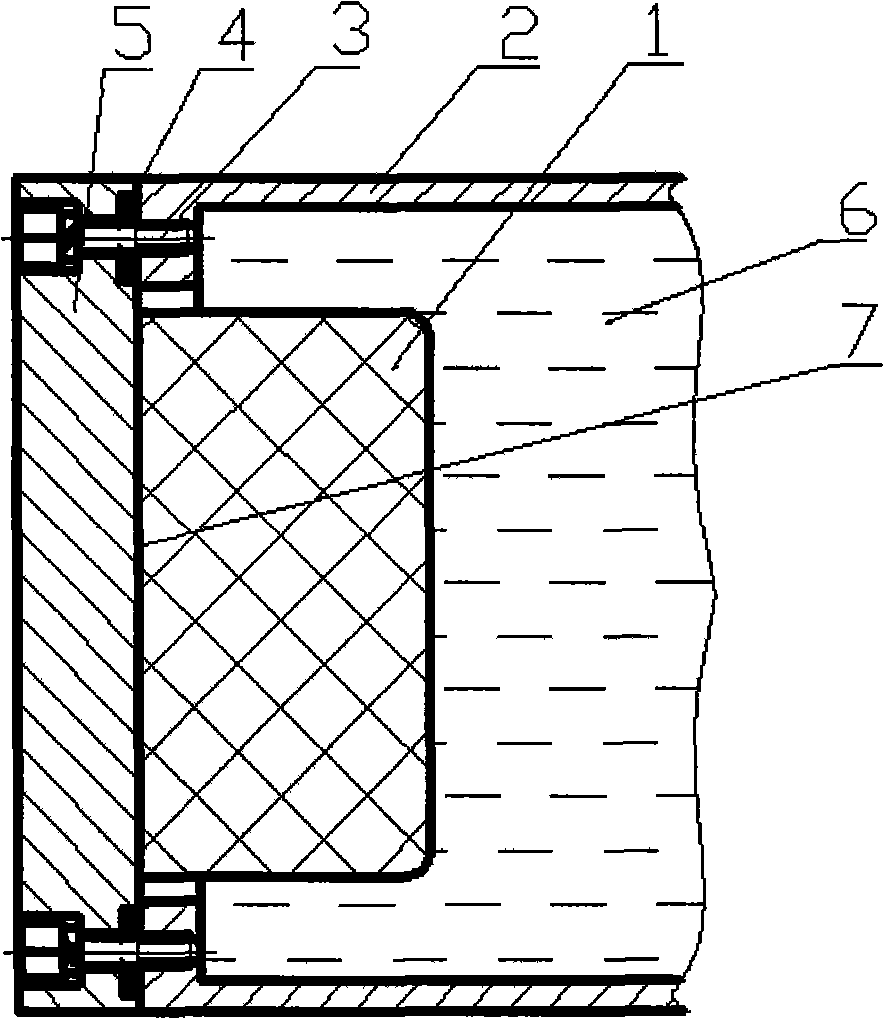

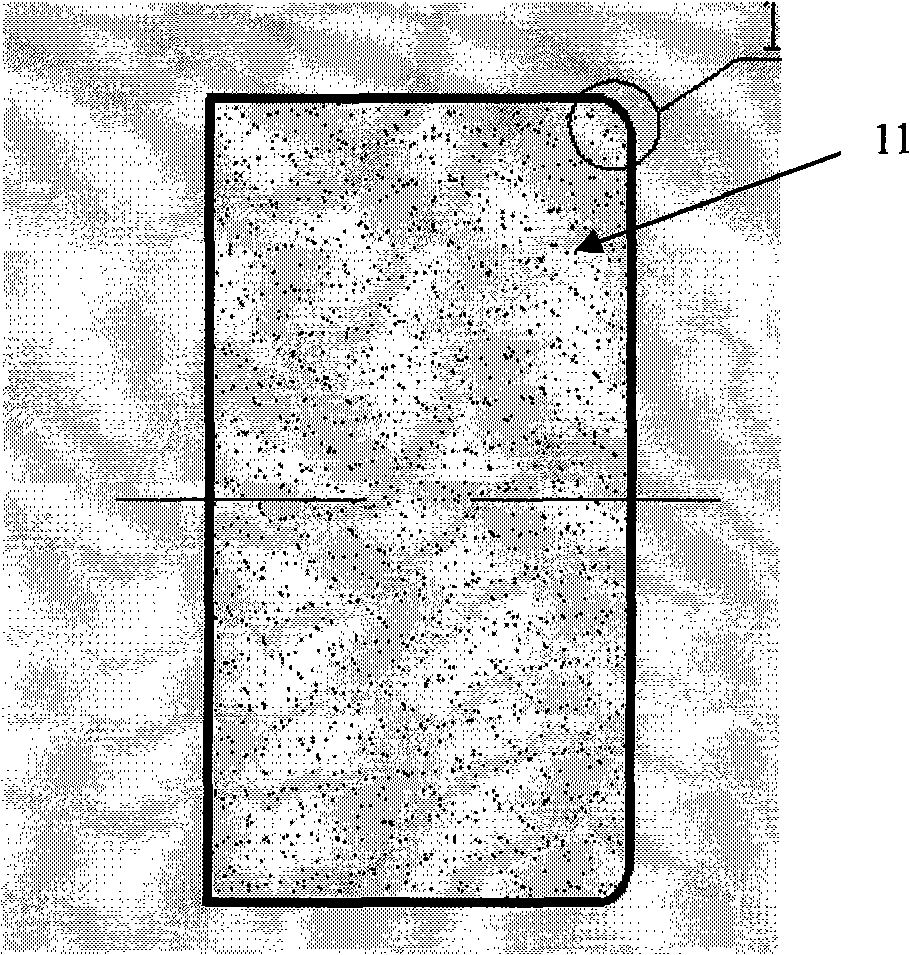

The invention relates to an X-ray tube solid packaging device, comprising an X-ray tube body (2), an inner hexagon screw (3), a sealed rubber flange (4), an end face sealed flange plate (5), an insulating oil (6) and an assembly glue (7); wherein, the inner surface of the end face sealed flange plate is bonded with at least one vacuum hole pressure-reducing rubber (11); the assembly glue (7) is evenly painted at one end (1) without reversed angles of vacuum hole pressure-reducing rubber (1); the vacuum hole pressure-reducing rubber (11) is in the middle of the end face sealed flange plate (5) with sealed ring-shaped slot section; the vacuum hole pressure-reducing rubber (11) comprises a rubber base (111) and a plurality of vacuum cavity (112) therein. Compared with the expansion capsule in the prior art, the vacuum hole pressure-reducing rubber of the invention does not bear the effect of sealing, and effectively reduces the phenomenon caused by that the fatigue deformation, aging, crack and break, etc. of the expansion capsule.

Description

X-ray tube solid packaging device used in X-ray fluorescence spectrometer technical field The invention relates to a sealing part of an X-ray tube used in an X-ray fluorescence spectrometer, in particular to a sealing device which adopts solid vacuum hole pressure-relieving rubber to assist in sealing the X-ray tube. Background technique At present, the oil-immersed sealed X-ray tube is mainly in the form of a rubber telescopic capsule, as shown in Figure 1, an insulating oil expansion part for an X-ray source. It consists of a shell, a sealing ring, a sealing flange, a telescopic capsule, a pressure ring, and a pressure ring. It is characterized in that the telescopic capsule is arranged in the shell, and its opening is outward, and one end is closed and integrated, and the other end is a The flanging plane form, the pressure ring ring and the pressure ring are sequentially arranged on the inner cylindrical surface of the flanging plane of the telescopic capsule, and the ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01J35/16G01N23/223

Inventor 胡晓斌

Owner JIANGSU SKYRAY INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com